Device for measuring paramagnetic oxygen and method for manufacturing and operating the said device for measuring oxygen

A measuring device, paramagnetic technology, applied in the direction of analysis using electron paramagnetic resonance, etc., can solve the problems of miniaturization limitation, short response time, and failure to reach, and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

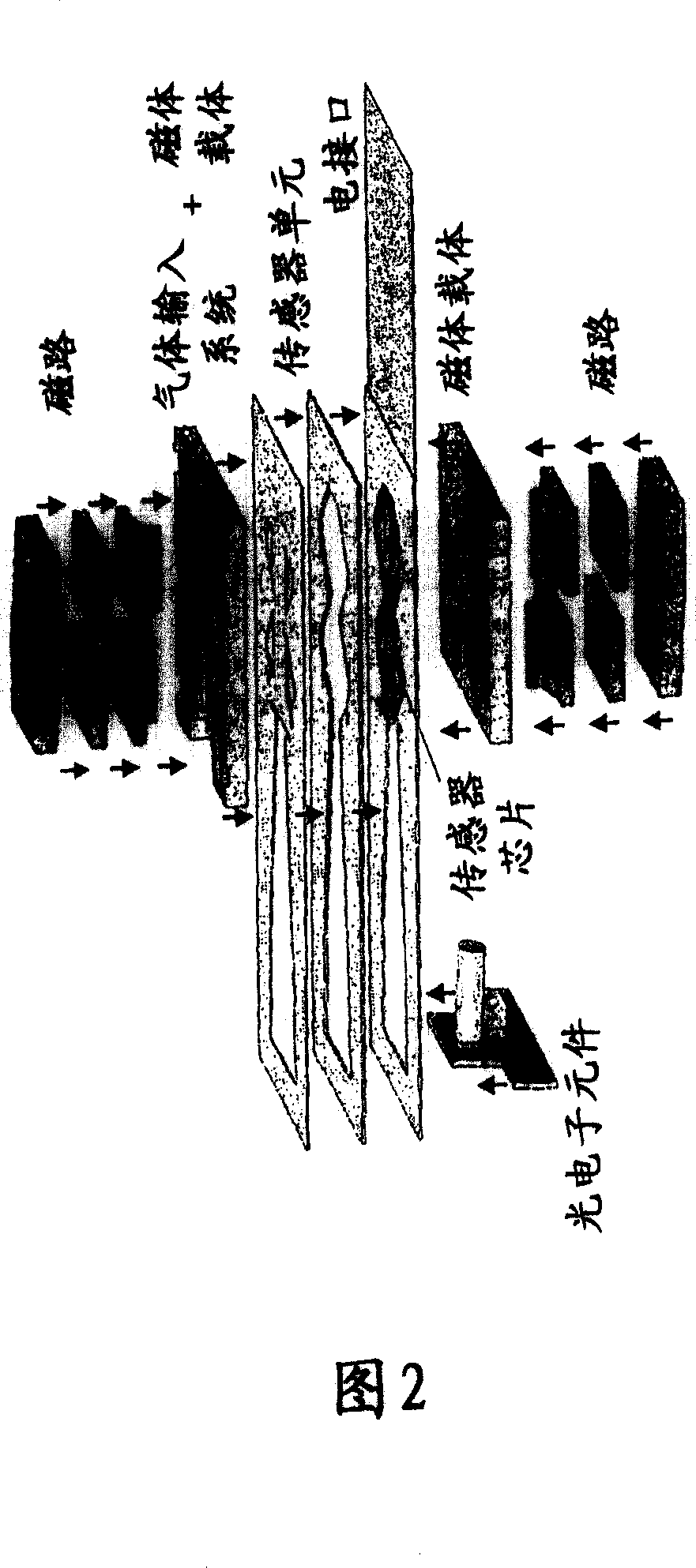

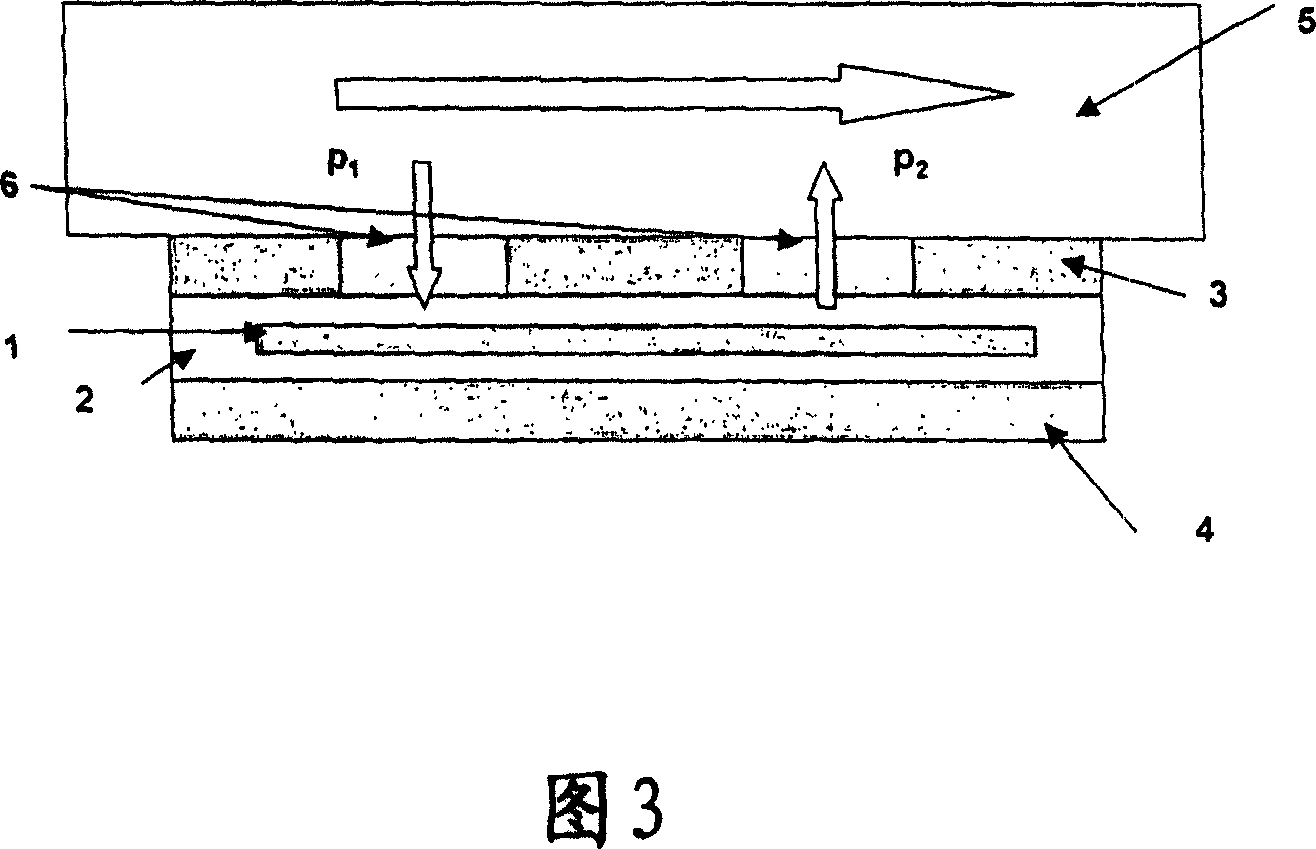

[0045] FIG. 1 shows a plan view of a paramagnetic oxygen measuring device, or a plan view of the interior of the sensor unit or of the measuring chamber, without side covers, ie open. The sample body typically has a length of 2 to 15 mm, a width of 0.5 to 3 mm and a height of 0.1 to 2 mm and consists of two compartments which are connected to each other via a bridge. Alternatively, the sample body can be designed as hollow or solid. The proportion selection of the empty chamber and the solid part on the sample body is determined by adjusting the required moment of inertia. According to the situation described here, the wall thickness of the bridge piece is 0.1mm, and the width is 0.2mm. The sample body, the spring parts and the assembly frame or holding frame are all made of silicon in one piece, for which purpose the individual parts are formed in their structure by etching methods such as anisotropic wet etching or anisotropic reaction Reactive ion etching, manufactured fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com