Lithium secondary battery

A lithium secondary battery and battery casing technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of battery overheating, Joule heat, expansion, etc., and achieve excellent short-circuit resistance and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

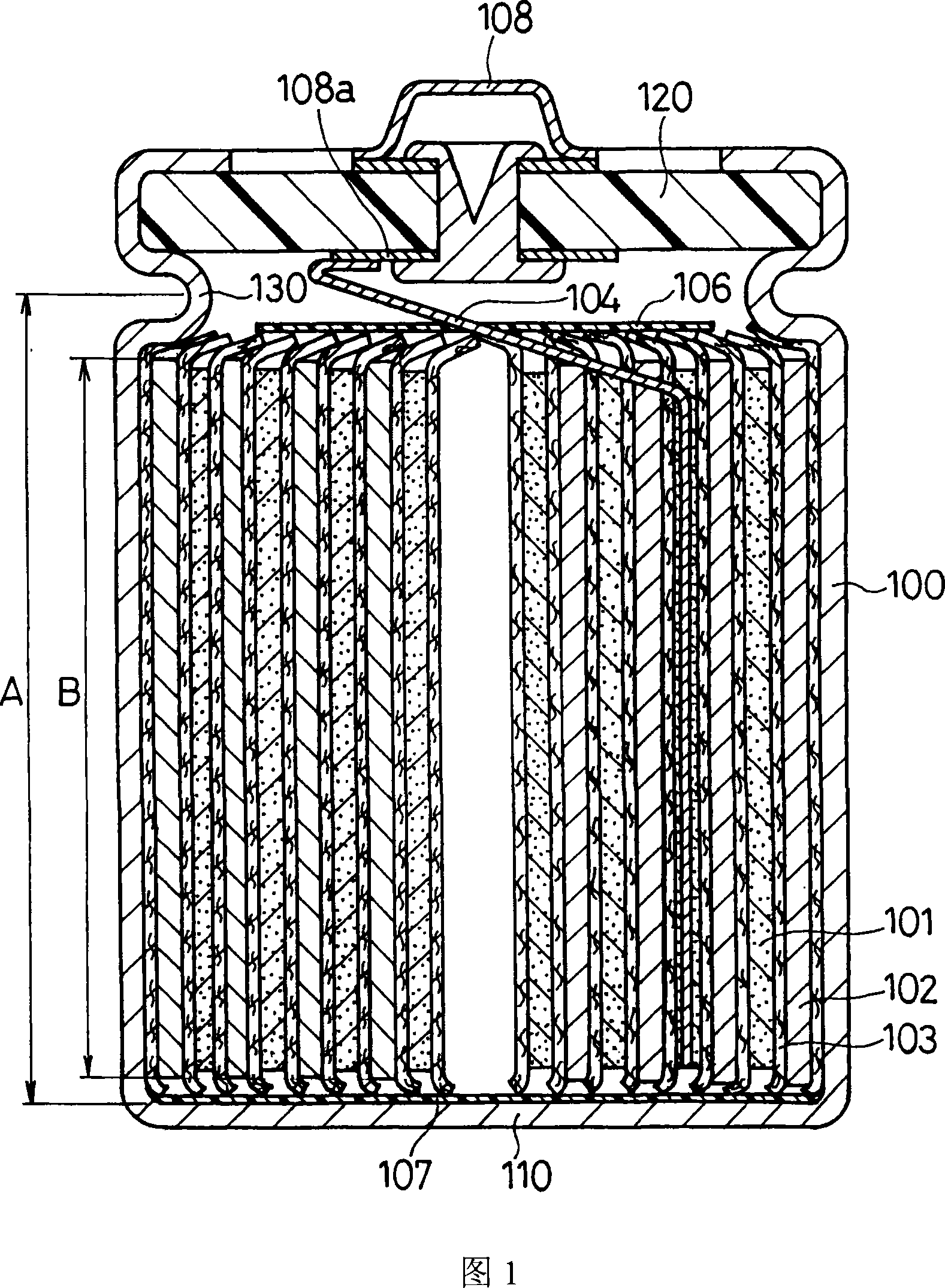

[0066] In this embodiment, the cylindrical lithium secondary battery shown in FIG. 1 is explained.

[0067] (Battery 1)

[0068] (i) Preparation of positive electrode

[0069] Using a double-arm kneader, 3 kg of lithium cobaltate, 1 kg of PVDF#1320 (N-methyl-2-pyrrolidone (hereinafter referred to as NMP) solution containing 12 wt % PVDF), 90 g of Kureha Chemical Industry Co., Ltd. Acetylene black and an appropriate amount of NMP were stirred to prepare a positive electrode mixture slurry. The resulting slurry was coated on both sides of a positive electrode core member comprising a 15 μm thick aluminum foil, dried and rolled to form a positive electrode with a positive electrode active material layer. The total thickness of the positive electrode was 160 μm. The positive electrode was cut into strips with a width of 56.5 mm.

[0070] (ii) Preparation of negative electrode

[0071] Using a double-arm kneader, the BM-400B (water dispersion containing 40wt% modified styrene-...

Embodiment 2

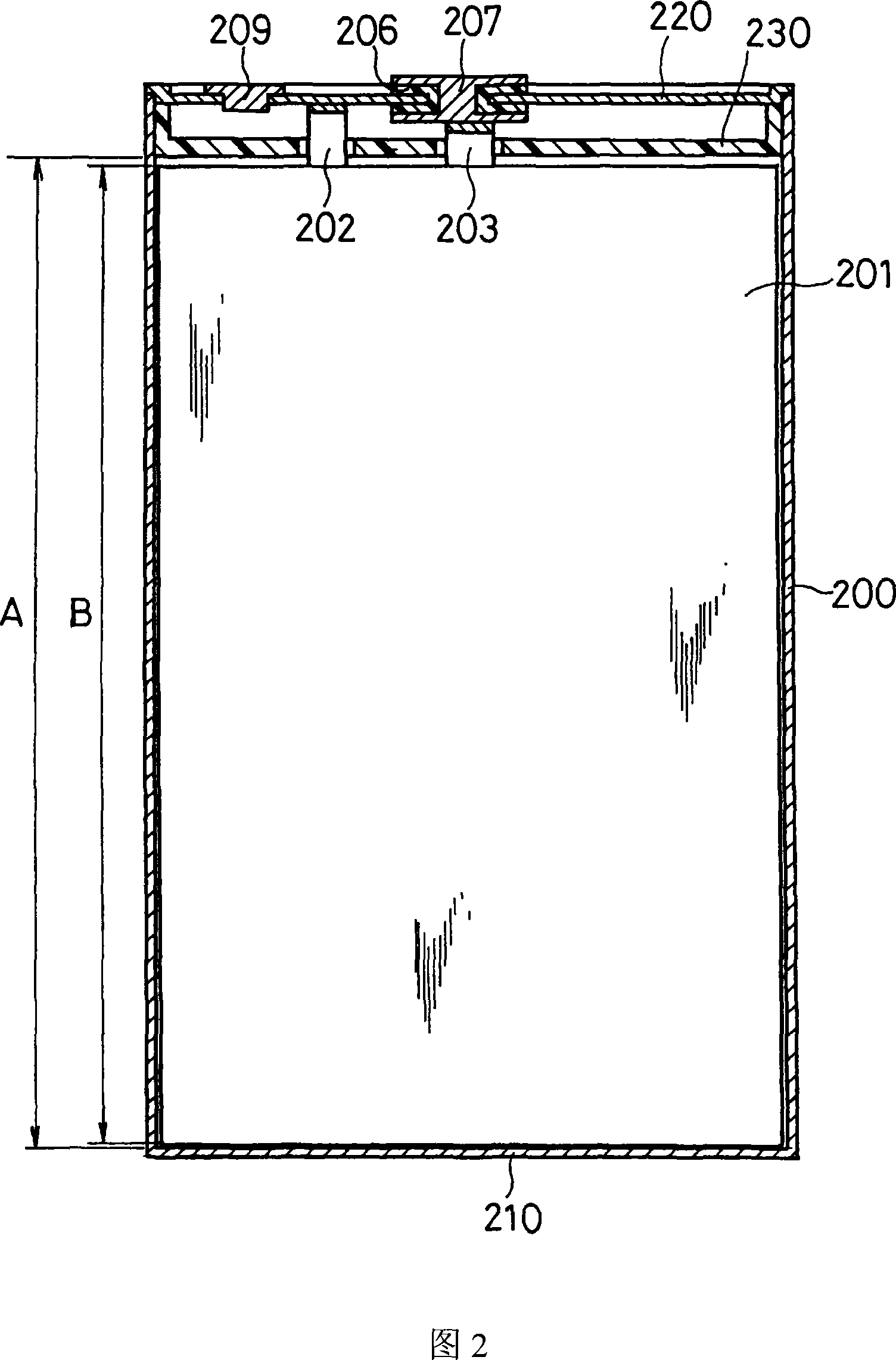

[0172] In this embodiment, the prismatic lithium secondary battery shown in FIG. 2 is explained.

[0173] (battery 31)

[0174] An electrode assembly was produced in the same manufacturing method as in Example 1 except for the following differences. The total thickness of the positive electrode becomes 150 μm, and the width of the positive electrode becomes 42.7 mm. The total thickness of the negative electrode became 150 μm, and the width of the negative electrode became 43.7 mm. The width of the diaphragm becomes 47 mm. The shape of the electrode assembly becomes an elliptical cylinder.

[0175] The resulting electrode assembly was inserted into an aluminum prismatic battery case of 49 mm high (bottom thickness: 0.5 mm), 34 mm wide, and 5.2 mm thick. After installing a 1.5 mm thick insulator on top of the electrode assembly, 2.5 g of the same electrolyte as in Example 1 was injected into the battery case. The distance A from the inner bottom surface of the battery case ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com