Collagen-chitosan / fibrin glue asymmetric bracket and the preparing method and the application thereof

A technology of fibrin glue and fibrinogen, applied in medical science, prosthesis, etc., to achieve the effect of good cell compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

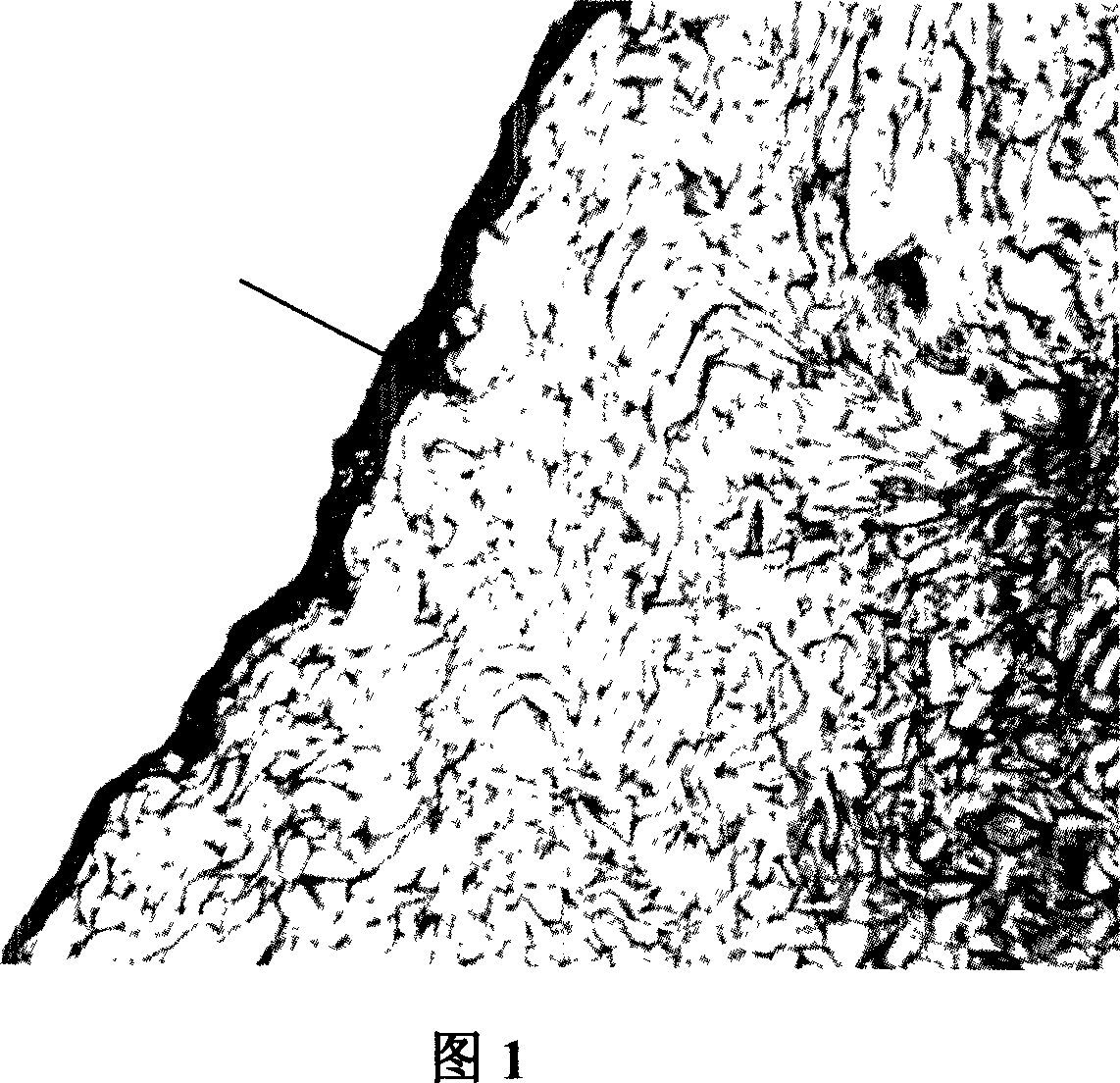

[0043] Histological observation of collagen-chitosan / fibrin glue asymmetric scaffold.

[0044] Collagen and chitosan were dissolved in 0.5mol / L acetic acid solution respectively, and a concentration of 0.5% collagen solution and a 0.5% chitosan solution were prepared, and the chitosan solution was added to the collagen solution, wherein chitosan The content of sugar (by weight) is 10%, and it is stirred evenly; it is frozen at -20° C. for 2 hours by a freeze-freeze-drying method, and then freeze-dried in a freeze dryer for 24 hours. The lyophilized collagen / chitosan scaffold was vacuum dry-heated and cross-linked in a vacuum oven at 105°C for 24 hours, and placed in 1-ethyl-3-3 (dimethylaminopropyl )-carbodiimide solution (40mmol / l) and N-hydroxysuccinimide mixed solution for cross-linking for 24 hours, after repeated rinsing with three distilled water, freeze-lyophilize again to obtain cross-linked collagen-chitosan Sugar porous scaffold. Place the collagen-chitosan porous ...

Embodiment 2

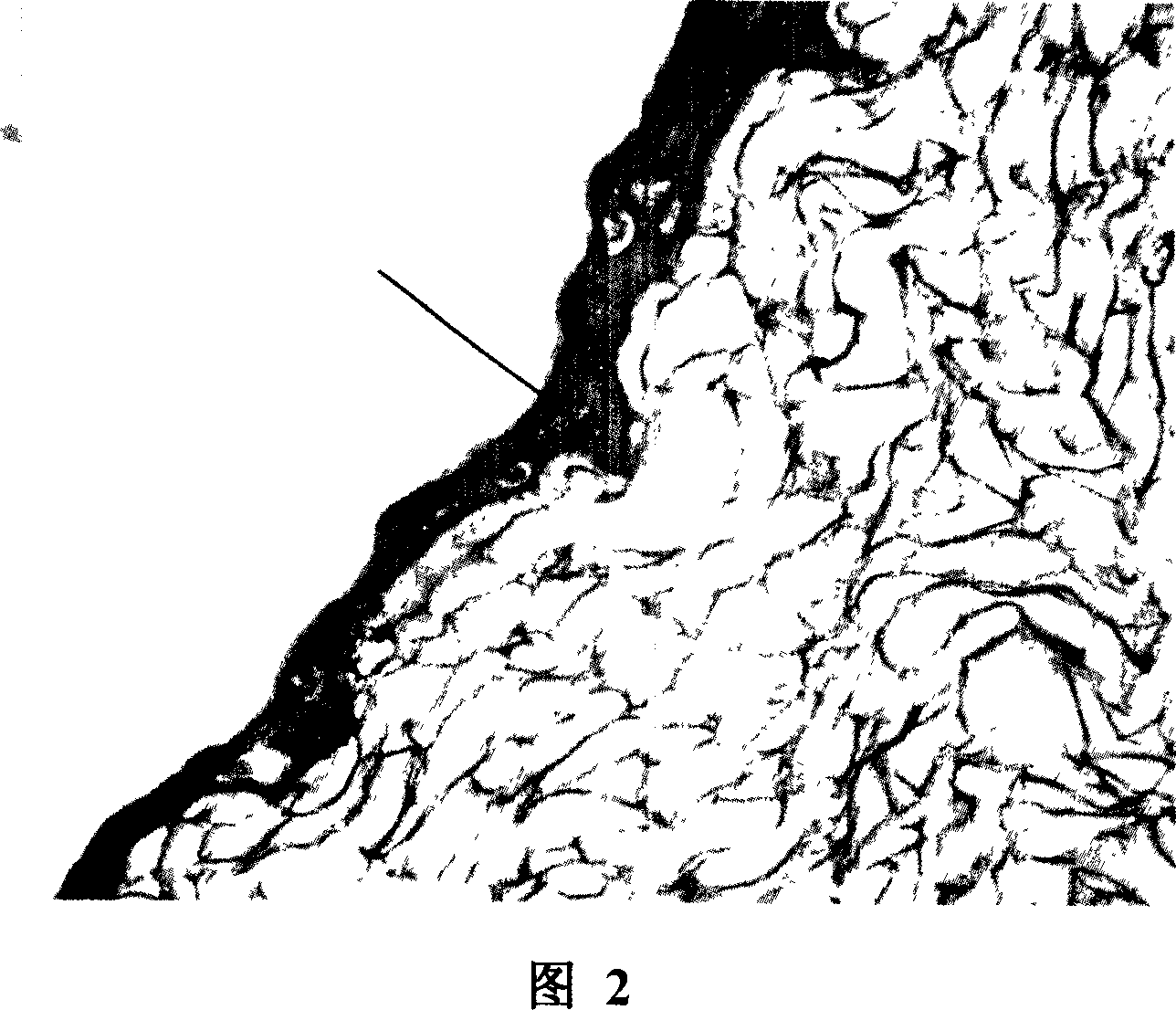

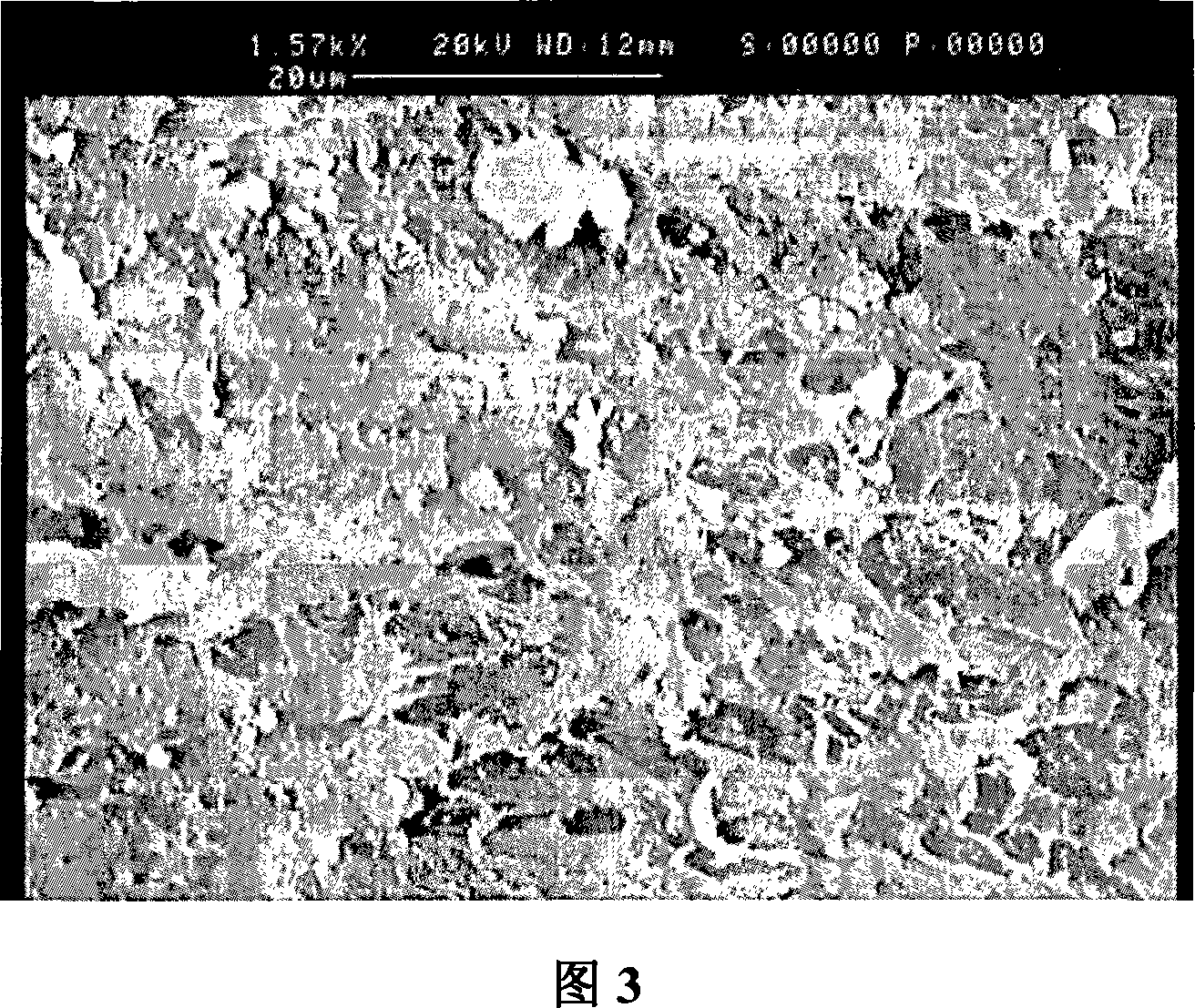

[0047] Ultrastructural observation of collagen-chitosan / fibrin glue asymmetric scaffold under scanning electron microscope.

[0048] Collagen and chitosan were dissolved in 0.5mol / L acetic acid solution respectively, and a concentration of 0.5% collagen solution and a 0.5% chitosan solution were prepared, and the chitosan solution was added to the collagen solution, wherein chitosan The content of sugar (by weight) is 10%, and it is stirred evenly; it is frozen at -20° C. for 2 hours by a freeze-freeze drying method, and then placed in a freeze dryer for 24 hours. The lyophilized collagen / chitosan scaffold was vacuum dry-heated and cross-linked in a vacuum oven at 105°C for 24 hours, and placed in 1-ethyl-3-3 (dimethylaminopropyl )-carbodiimide solution (40mmol / l) and N-hydroxysuccinimide mixed solution for cross-linking for 24 hours, after repeated rinsing with three distilled water, freeze-lyophilize again to obtain cross-linked collagen-chitosan Sugar porous scaffold. Pla...

Embodiment 3

[0051] Study on Cytocompatibility of Collagen-Chitosan / Fibrin Glue Asymmetric Scaffold

[0052] Collagen and chitosan were dissolved in 0.5mol / L acetic acid solution respectively, and a concentration of 0.5% collagen solution and a 0.5% chitosan solution were prepared, and the chitosan solution was added to the collagen solution, wherein chitosan The content of sugar (by weight) is 10%, and it is stirred evenly; it is frozen at -20° C. for 2 hours by a freeze-freeze-drying method, and then freeze-dried in a freeze dryer for 24 hours. The lyophilized collagen / chitosan scaffold was vacuum dry-heated and cross-linked in a vacuum oven at 105°C for 24 hours, and placed in 1-ethyl-3-3 (dimethylaminopropyl )-carbodiimide solution (40mmol / l) and N-hydroxysuccinimide mixed solution for cross-linking for 24 hours, after repeated rinsing with three distilled water, freeze-lyophilize again to obtain cross-linked collagen-chitosan Sugar porous scaffold.

[0053] Soak the collagen-chitosa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com