Fluidized bed pelletizing process and special coating machine for coating tree seed

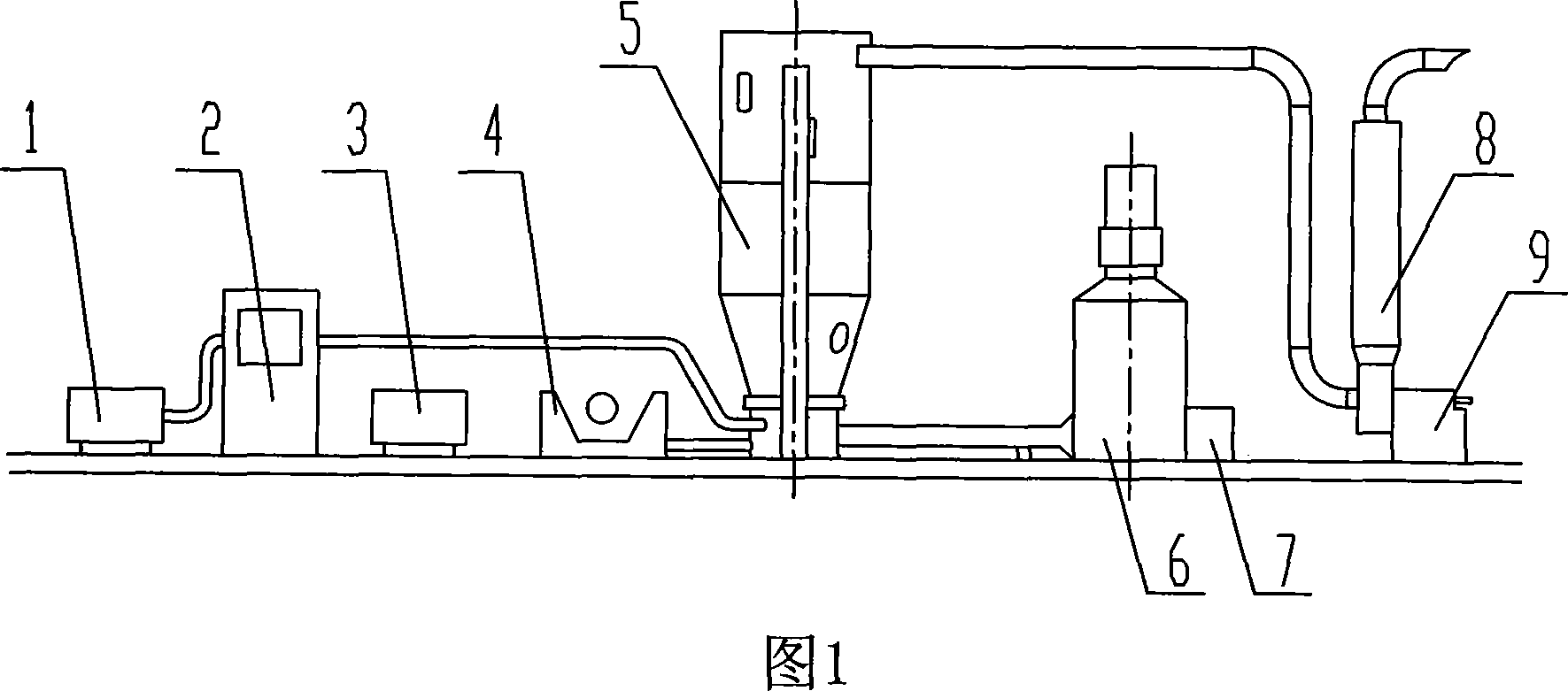

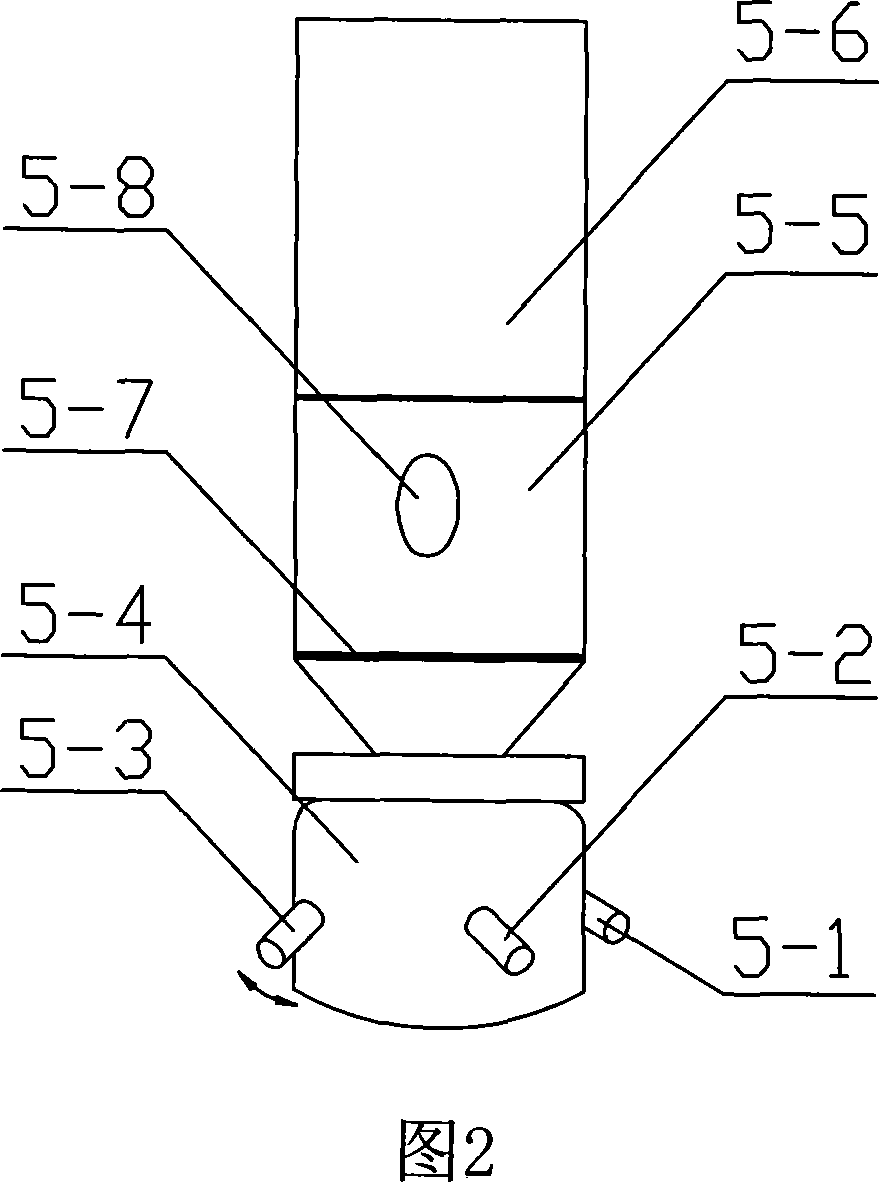

A technology of boiling granulation and sandwich pills, applied in the direction of seed coating/seed dressing, etc., can solve the problems of difficulty in ensuring single seed rate, easy to bond and form agglomeration, lack of research on granulation technology, etc. , the effect of increasing growth and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

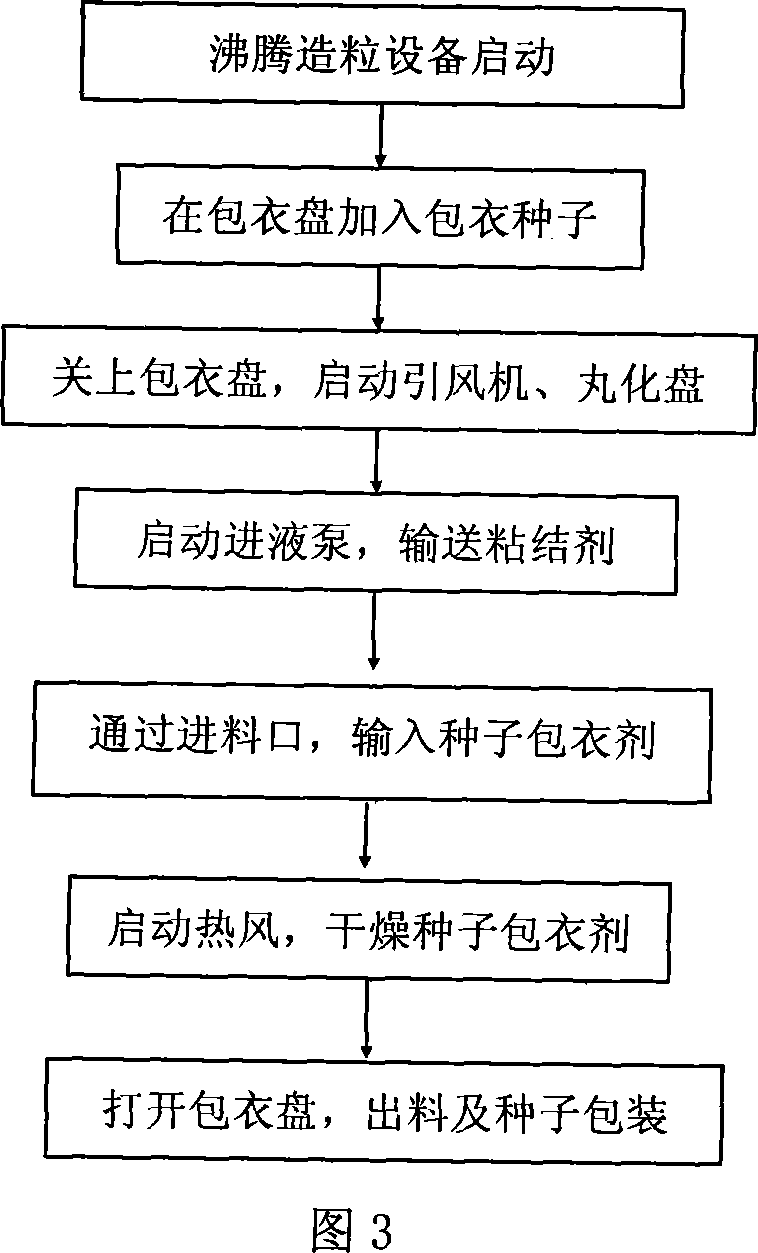

[0056]Embodiment 1, this example is used for the coating pelletization of sweetgum sweetgum seed, and seed pitchy, oblong shape, processing technology flow is as follows (referring to Fig. 4):

[0057] a) Seed pre-selection, the main purpose is to use manual screening to remove most of the large impurities such as dust and chaff and light impurities such as dander and dust, so as to lay the foundation for further seed processing and effectively ensure the air cleanliness of the processing site , Eliminate the hidden danger of dust explosion and protect the health of operators.

[0058] b) The air sieve selects the seeds, and uses frequency conversion to control the wind speed and adjust the air volume, so that the seeds in free fall will be separated due to the different quality under the action of wind force. Unsaturated seeds with low mass are blown away by the wind, which also effectively removes dust.

[0059] c) Inner layer coating, pour 500 grams of selected seeds into ...

Embodiment 2

[0066] Example 2. This example is used for the coating pelletization of Schima superba seeds, which are flat, kidney-shaped, and have wings on the edges. The processing process is as follows:

[0067] a) Seed pre-selection, the main purpose is to use manual screening to remove most of the large impurities such as dust and chaff, and light impurities such as dander and dust.

[0068] b) The air sieve selects the seeds, and uses frequency conversion to control the wind speed and adjust the air volume, so that the seeds in free fall will be separated due to the different quality under the action of wind force.

[0069] c) Inner layer coating, pour 500 grams of selected seeds into the coating machine, start the coating machine, make the seeds boil, and spray the binder into the seeds with a high-pressure spray gun, and the binder is made of poly It is prepared by mixing 5% by weight of vinyl alcohol and 98% by weight of water.

[0070] The first dosage is about 5% of the seed we...

Embodiment 3

[0074] Embodiment 3, this example is used for the coating pelletization of duying seed, and the seed is generally oval and spherical. The processing process is as follows:

[0075] a) Seed pre-selection, the main purpose is to use manual screening to remove most of the large impurities such as dust and chaff, and light impurities such as dander and dust.

[0076] b) The air sieve selects the seeds, and uses frequency conversion to control the wind speed and adjust the air volume, so that the seeds in free fall will be separated due to the different quality under the action of wind force.

[0077] c) Inner layer coating, pour 1500 grams of selected seeds into the coating machine, start the coating machine, make the seeds boil, and spray the seeds with a high-pressure spray gun. It is prepared by mixing 4% by weight of vinyl alcohol and 96% by weight of water. The first dosage is about 5% of the seed weight, i.e. 75g, so that the binding agent is evenly distributed on the seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com