Olefin polymer, producing method and application thereof

A technology of olefin comonomers and olefins, applied in applications, other household appliances, household appliances, etc., can solve problems such as poor blending of comonomers, failure to obtain approval, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

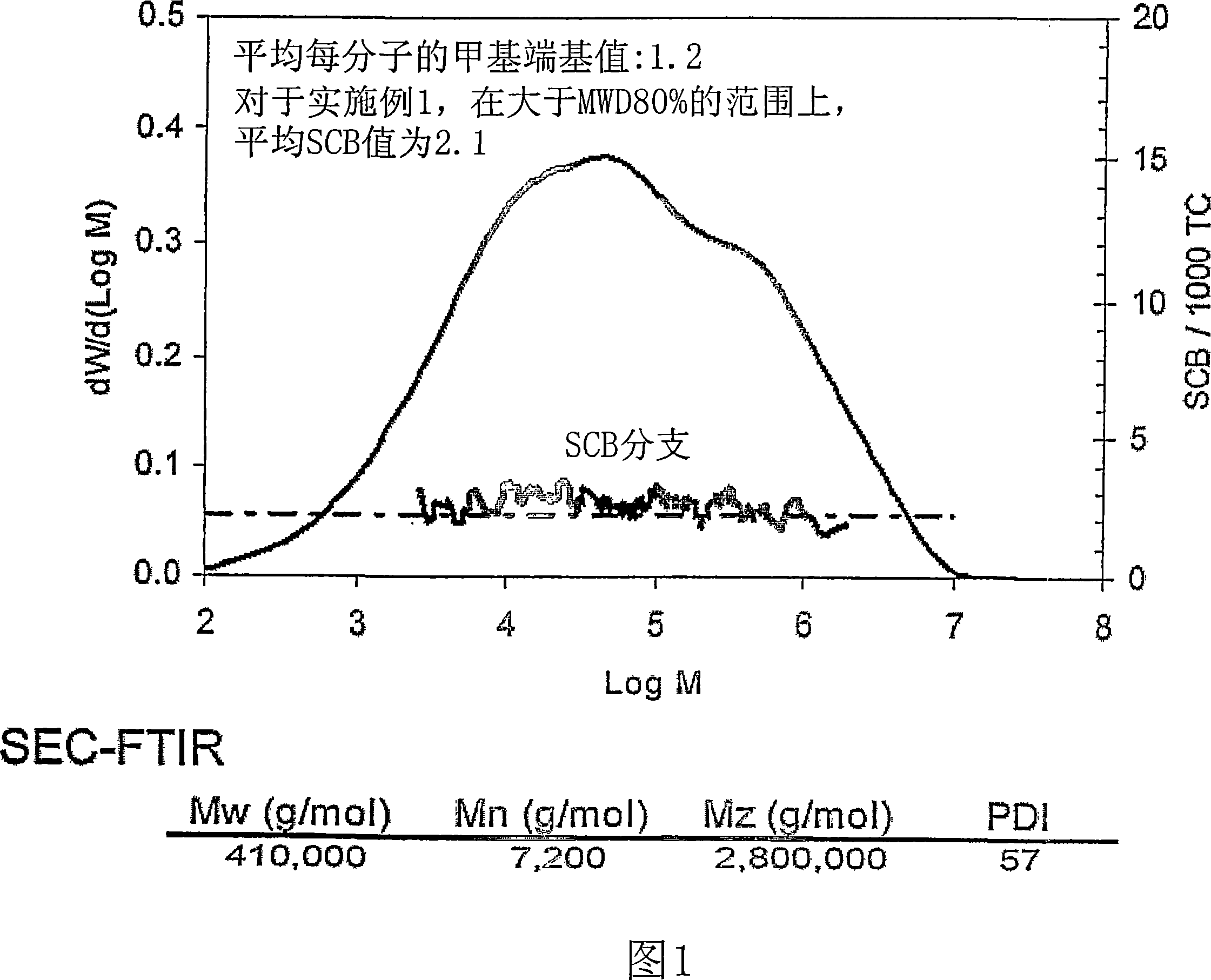

Embodiment 1

[0124] Catalyst Activation

[0125] The above-mentioned catalyst was activated by calcining in dry air at 600°C. In a typical activation batch, about 500 lbs of catalyst are charged to a commercial activator consisting of a perforated plate located inside an Inconel cylinder about 20 feet high and 42 inches in diameter. The catalyst was placed on a perforated plate and dry air passed through at a rate of about 0.2 feet per second (ft / sec) to fluidize the bed. The temperature was gradually increased to about 600°C over a period of about 8-10 hours. Once the temperature reached 600°C, the activator was maintained at that temperature, while fluidizing, for about 10 more hours. The activated catalyst is then cooled to about 300°C, at which temperature the activated catalyst is removed from the activator. During the last 2-3 hours of the cooling process, the fluidizing air was replaced with dry nitrogen. Catalyst removed from the activator was kept in nitrogen-blanketed airtigh...

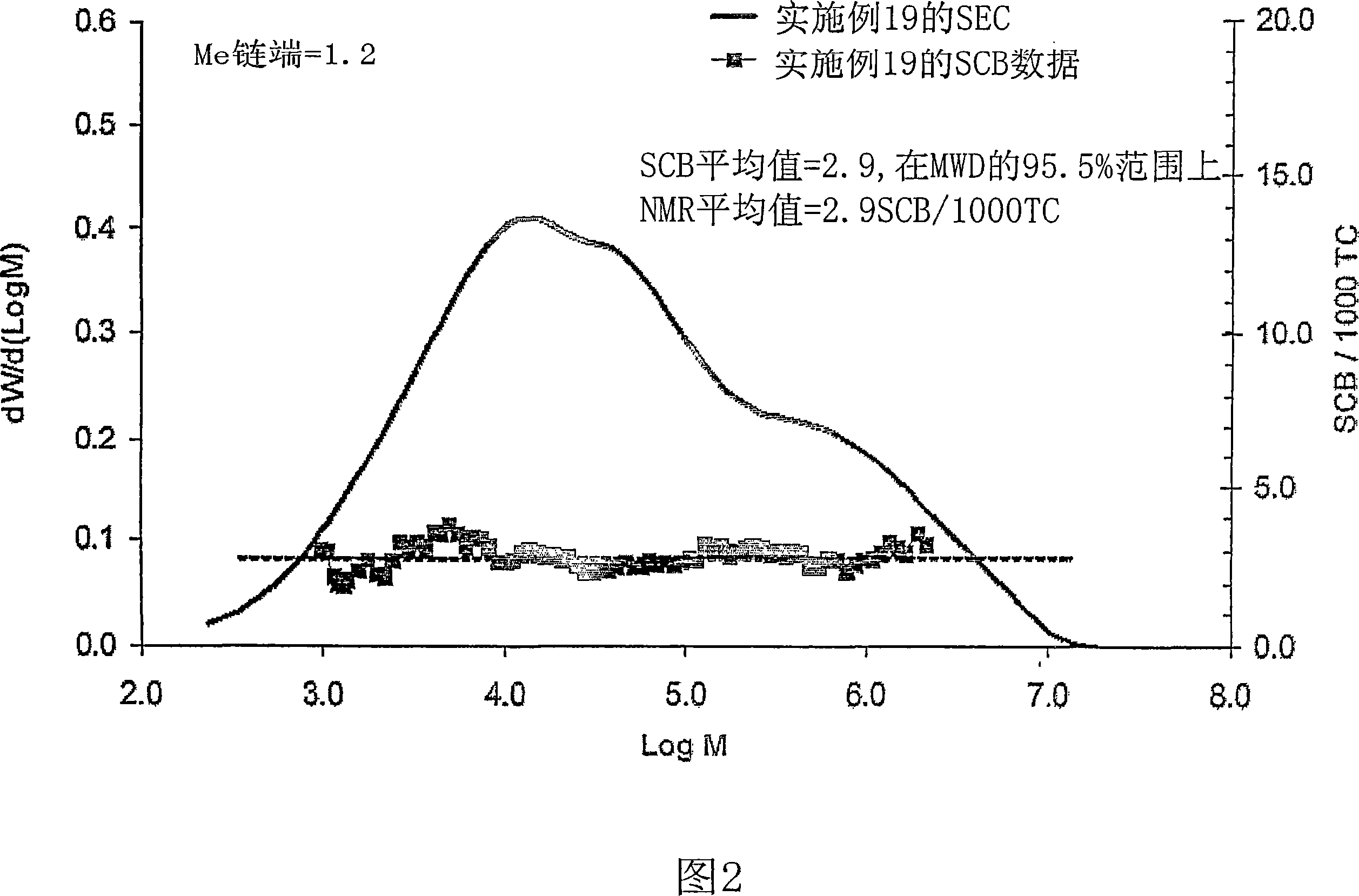

Embodiment 2-19

[0133] Catalyst preparation:

[0134]Several pilot runs were carried out using the catalyst system of the present invention. These examples also adopt the steps of preparing the catalyst in Example 1, only adjusting the amount of phosphoric acid added to the preparation process and changing the P / Al molar ratio in the final catalyst. Other steps are the same. In all cases, catalyst activation was carried out analogously in a fluidized bed at about 600°C under air conditions. 1.5 lbs of catalyst was charged into a 6 inch diameter cylinder with a distribution plate for fluidization. The catalyst was fluidized with dry air during the temperature rise to about 600°C. This process takes about 8 hours, and then the catalyst is fluidized for another 6 hours at about 600°C in dry air. The catalyst was purged with dry nitrogen during cooling and then kept under nitrogen until use.

[0135] polymerization

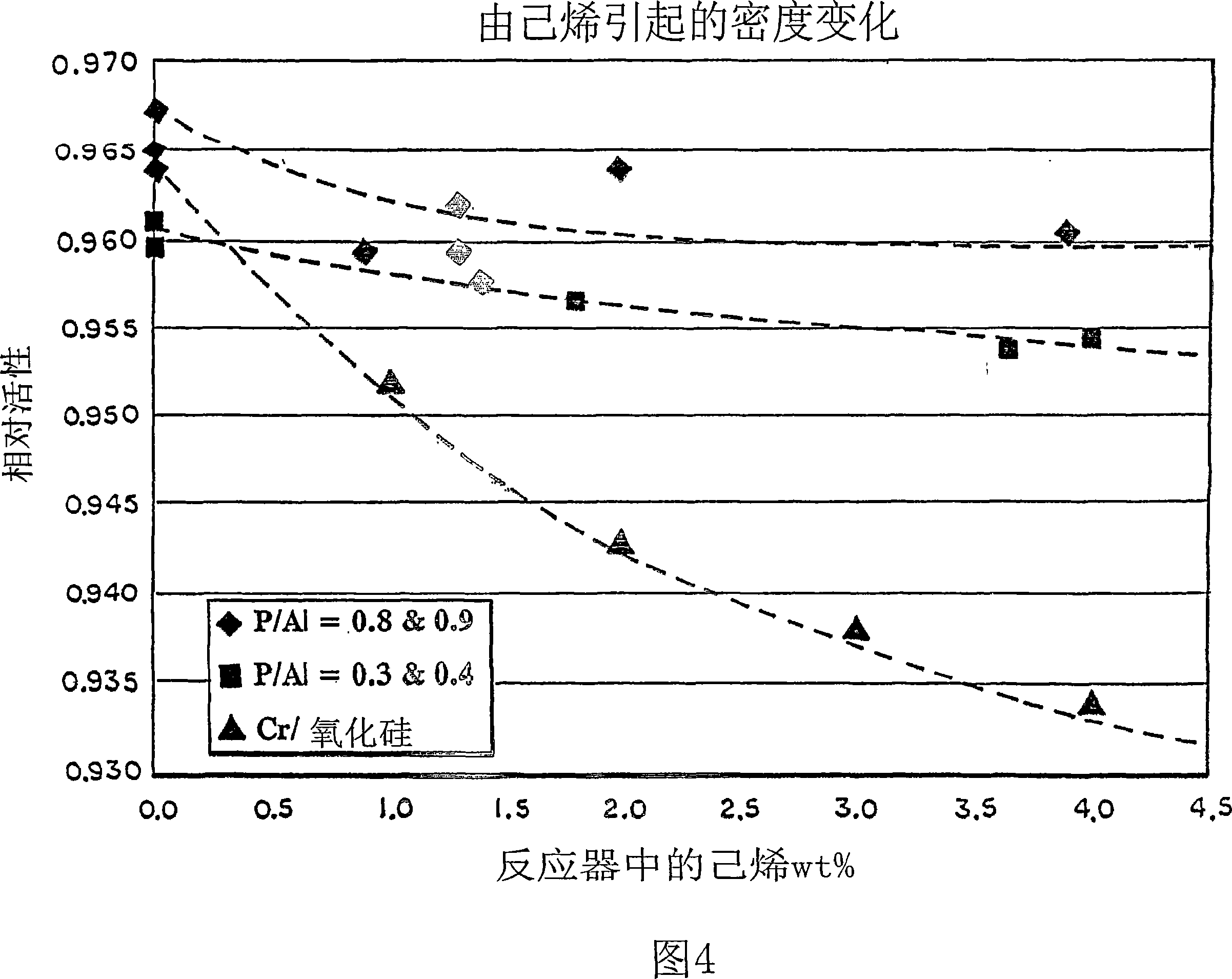

[0136] In Examples 2-19, ethylene polymers were prepared in a continuous p...

Embodiment 20

[0161] This example illustrates the preparation of various catalyst systems employed in the following examples.

[0162] Chromium / Aluminophosphate Catalyst System

[0163] (Chromium / Aluminophosphate Catalyst Systems)

[0164] The aluminum phosphate catalyst system is prepared from a thick slurry comprising anhydrous aluminum nitrate, monobasic ammonium phosphate and chromium nitrate. A small amount of water is added, usually about the amount of aluminum nitrate, and the temperature is raised to about 40°C (104°F) to dissolve the mixture. The addition amount of aluminum nitrate and monobasic ammonium phosphate is the required amount according to the expected molar ratio of phosphorus to aluminum (P / Al). For example, in order to make the phosphorus-aluminum molar ratio (P / Al) of the final catalyst system 0.2, for each mole of anhydrous aluminum nitrate, 0.2 mole of monobasic ammonium phosphate (or ammonium phosphate monobasic, (ammonium phosphate monobasic)) is correspondingly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com