Glue-jointed hardalloy composite roller ring

A cemented carbide ring, cemented carbide technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of expensive cemented carbide cost, increased thickness of cemented carbide roll ring, and decreased performance of cemented carbide. , to achieve the effect of convenient manufacturing, improved impact resistance and torque transmission capacity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

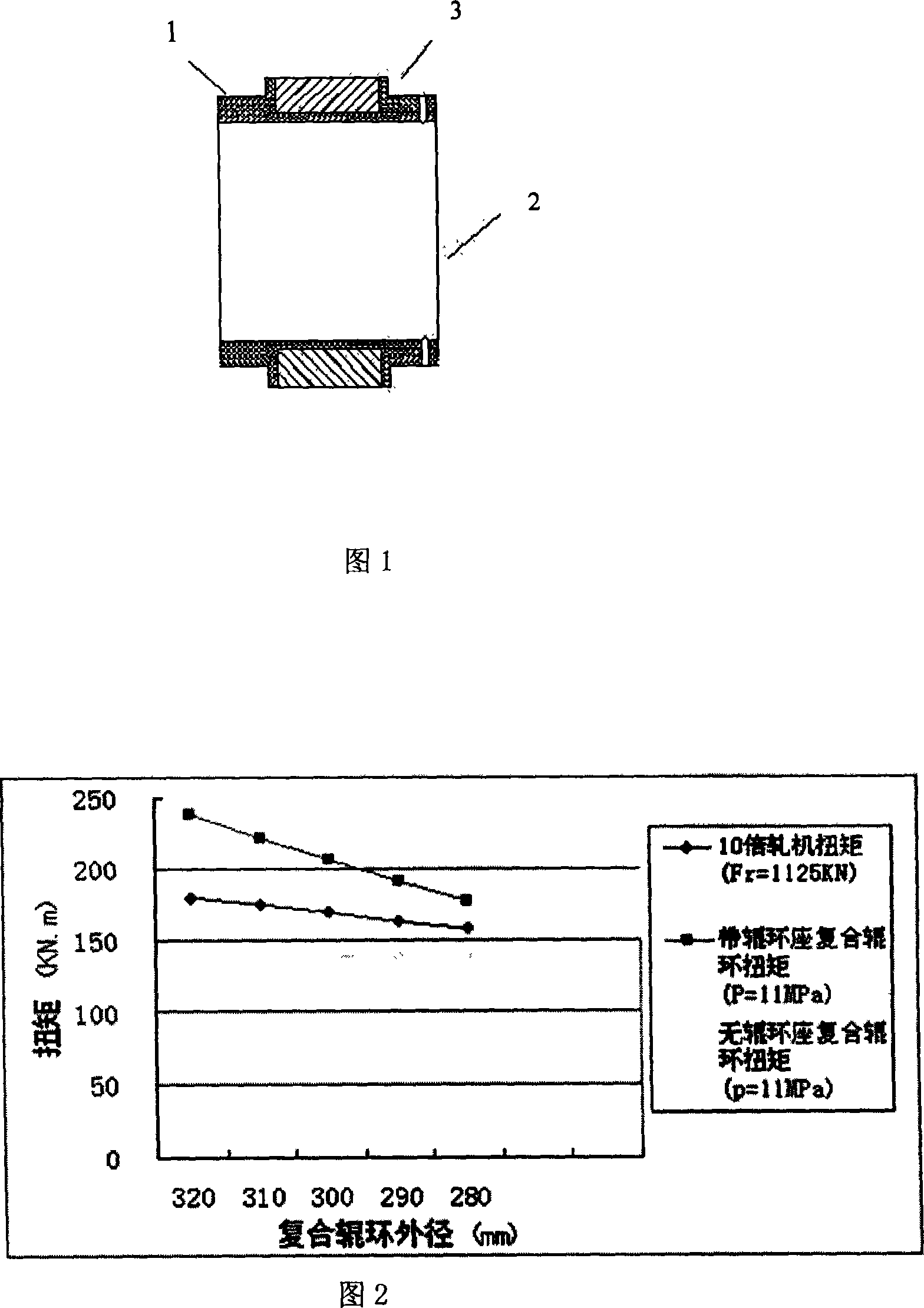

[0020] Example 1: Application on finished stand of bar mill

[0021] The invented cemented composite roll ring is combined with the roller R6 to form a composite roll. The test is carried out on the finished stand of the Pomini bar mill. The mill torque: M1=18KN, the diameter of the rolling groove is Φ116mm; 250mm, length 130mm, and the roller ring seat is bonded with chemical glue; the inner diameter of the composite roller ring seat is 230mm, and the end surface is combined with a keyway and a fastening nut. The experimental results are shown in Table 1.

[0022] Table 1: The amount of steel passing through the composite roll ring on the finished bar frame

[0023] rack

[0024] Average steel passing capacity of single groove

example 2

[0025] Example 2: Application on the front frame of the finished bar

[0026] The invented cemented composite roll ring is combined with the roller R6 to form a composite roll. The test is carried out on the finished stand of the Pomini bar mill. The mill torque: M1=18KN, the diameter of the rolling groove is Φ18mm; the outer diameter of the hard alloy roll ring is 320mm, The inner diameter is 250mm, the length is 130mm, and the roller ring seat is bonded with chemical glue; the inner diameter of the composite roller ring seat is 230mm, and the end surface is combined with a keyway and a fastening nut. The experimental results are shown in Table 2.

[0027] Table 2: The amount of steel passed by the composite roll ring in the front frame of the finished bar

[0028] rack

example 3

[0029] Example 3 Strip Mill

[0030] Assume that the maximum torque of a strip mill M=80KN.m, the radial rolling force Fr=5000KN, the width of the working face h=100mm, the outer diameter of the hard alloy roll is r=320mm, the allowable grinding is 20mm, and the inner diameter d=250mm, Composite roll ring transmits torque safety factor = 10. It can be seen from calculation that the composite roll ring without end faces requires a composite layer shear strength of 82MPa. Obviously, it is difficult for chemical glue to guarantee this strength. However, if the composite roller ring with a roller ring seat is used, the shear strength of the cemented layer can reach 50 MPa. Obviously, this can be achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com