Structure of material with sereo depth-field effect and making method therefor

A manufacturing method and depth-of-field technology, which can be used in the direction of imitating patterns with three-dimensional effects, patterns characterized by projection effects, chemical instruments and methods, etc., can solve problems such as inability to make properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

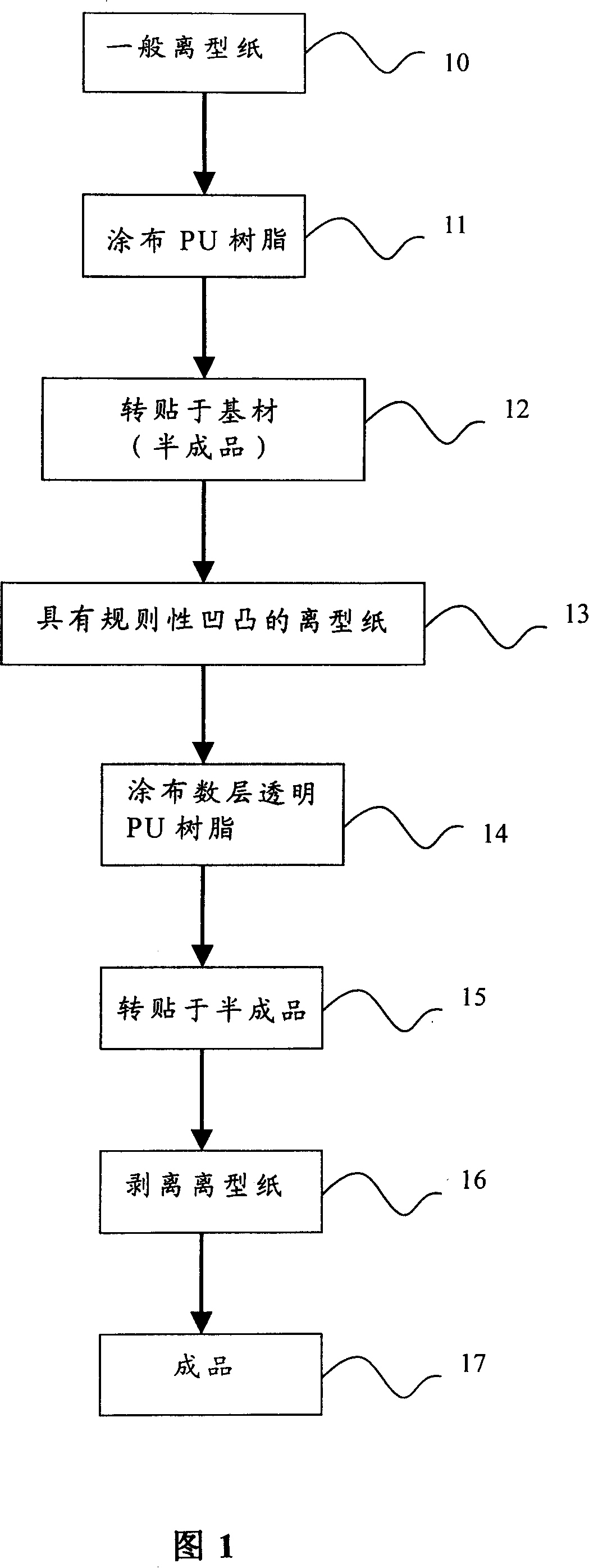

Method used

Image

Examples

Embodiment 1

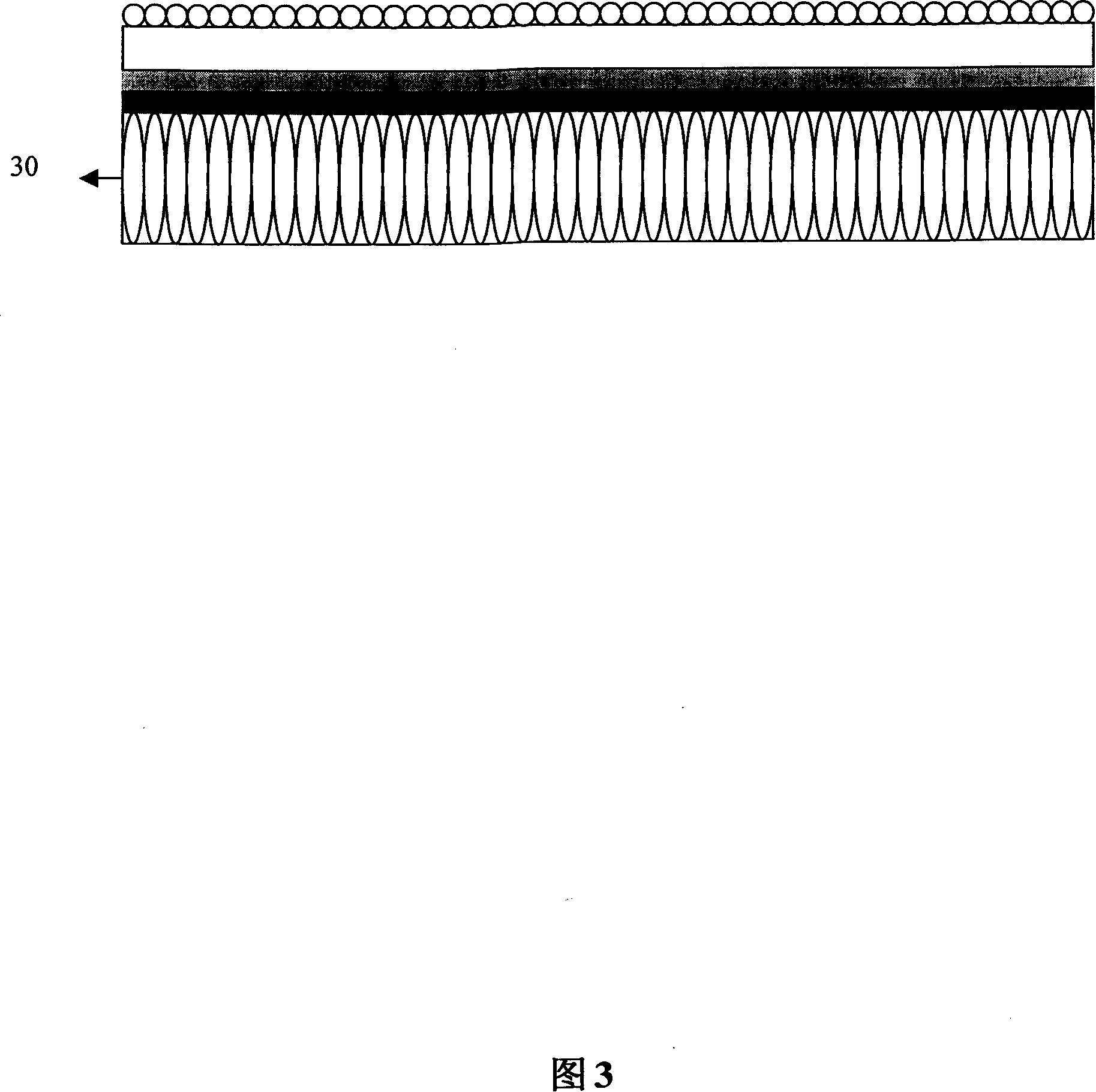

[0031] As shown in Figure 3, apply the polyurethane resin composition (attachment amount 240g / yw2) on the release paper with general texture, dry it and paste it, and transfer the texture of the release paper to a 1.1m / m ultrafine fiber sheet On the object 30; and then coated with a transparent polyurethane resin composition (attachment amount 240g / yw2) on the release paper with regular surface, thick in the middle and thin at the edge, and then laminated after drying, and transferred the texture of the release paper to the super On the thin fiber semi-finished product, a material with a three-dimensional depth of field effect is obtained.

Embodiment 2

[0033] As shown in Figure 4, apply the polyurethane resin composition (attachment amount: 240g / yw2) on the release paper with general texture, dry it and paste it, and transfer the texture of the release paper to a 1.1m / m superfine fiber sheet On the object, a printing layer 40 is formed by printing on it with chemicals (attachment amount 60g / yw2) and wheels (120Mesh), and finally, the surface is regularly coated with a concave-convex pattern release paper with regular thickness in the middle and thin edges. The cloth transparent polyurethane resin composition (attachment amount: 240g / yw2) is dried and pasted, and the texture of the release paper is transferred to the microfiber semi-finished product to obtain a material with a three-dimensional depth of field effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com