Dicyclopentadiene continuous cracking novel process

A technology of dicyclopentadiene and monocyclopentadiene, which is applied in the field of continuous production of monocyclopentadiene, can solve the problems of uneven flow velocity distribution of cracking tubes, large radial temperature difference of cracking tubes, insufficient energy supply, etc., and achieve reduction The effect of coking amount, extension of coke cleaning cycle and reduction of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

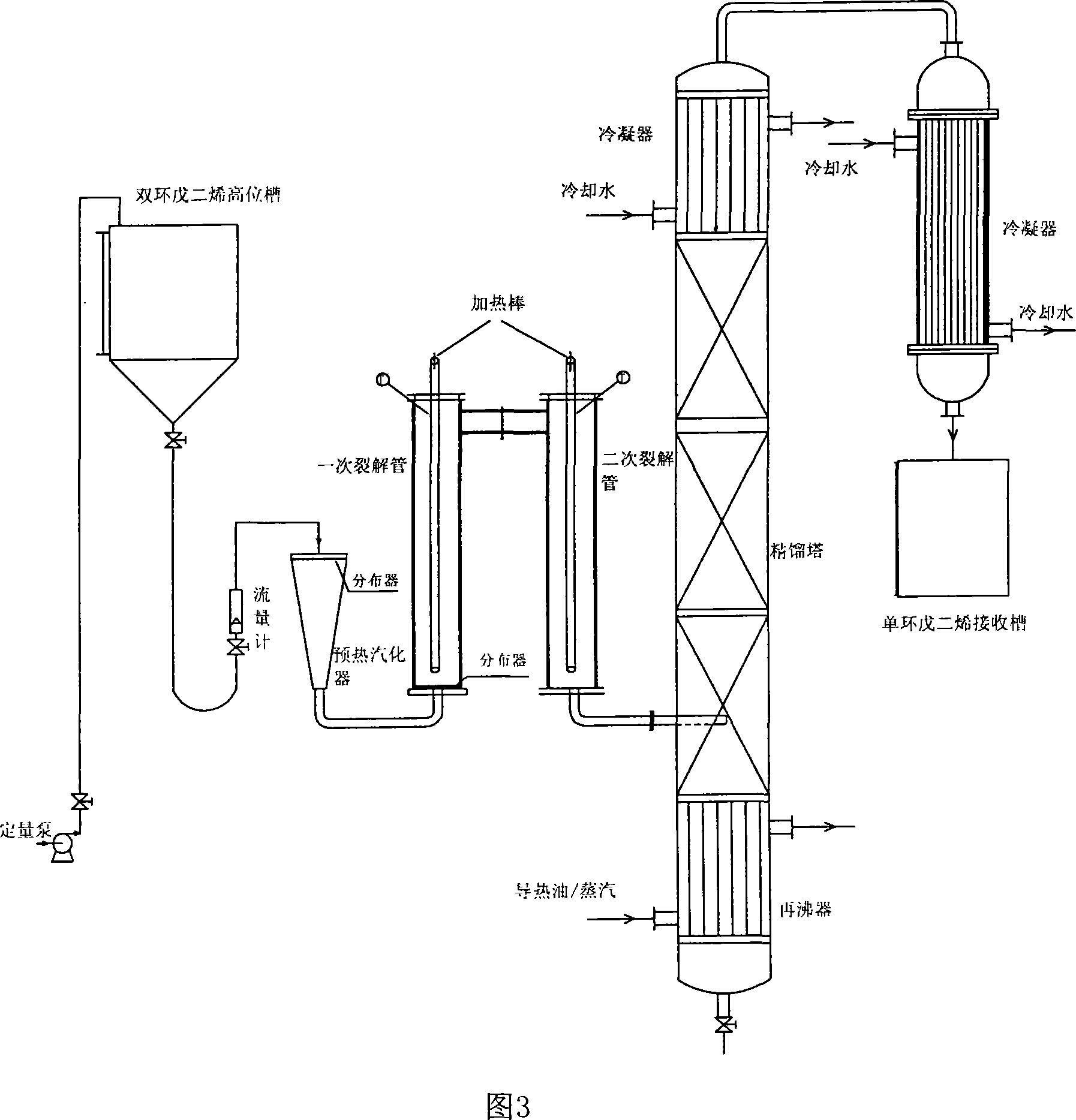

[0026] The specific equipment and process flow are shown in Figure 3, and the inside of the cracking tube is heated by a heating rod.

[0027] Equipment selection: the vaporizer is made of stainless steel, the heat exchange area is 4 square meters, the electric heating power of the primary cracking tube is 30KW, and the electric heating power of the secondary cracking tube is 36KW. The cracking tube is made of stainless steel 316L with a diameter of Φ315×10mm and a length of 2000mm. The stainless steel filler has a diameter of 600×8mm and a height of 8000mm.

[0028] First, put dicyclopentadiene into the dicyclopentadiene high tank with a quantitative pump. When the temperature of the preheated vaporizer reaches 200°C, start quantitatively feeding dicyclopentadiene into the vaporizer at a speed of 5kg / min to ensure that dicyclopentadiene is in the vaporizer. Completely vaporized in the medium, then enter the primary cracking tube, the temperature of the primary cracking tube i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com