Process for removing N-nitroso-pendimethalin from pendimethialin

A technology of nitroso pendimethalin and pendimethalin, applied in chemical instruments and methods, preparation of amino compounds from amines, preparation of amino compounds, etc., can solve the problems of reducing the content of nitrosamines and not being able to use them , to achieve the effects of lowering the denitration temperature, reducing the amount of removing agent, and lowering the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

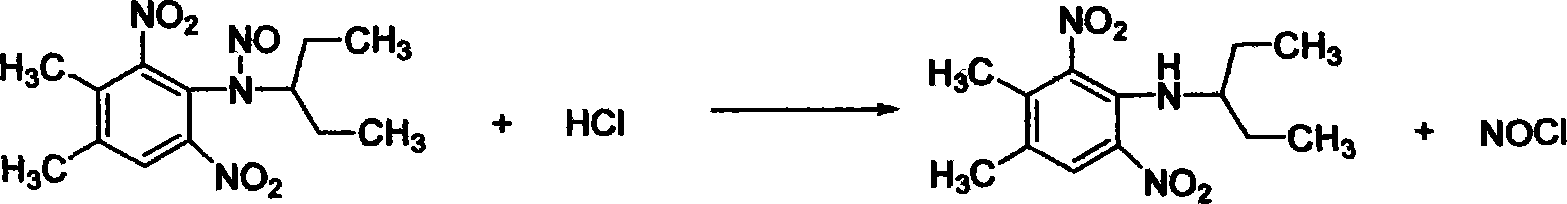

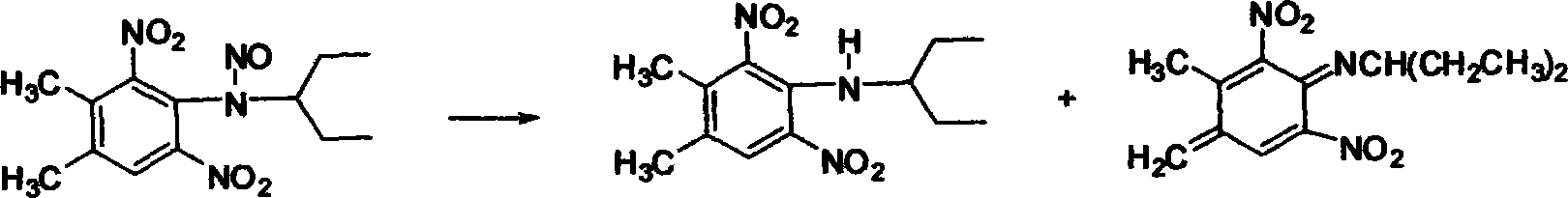

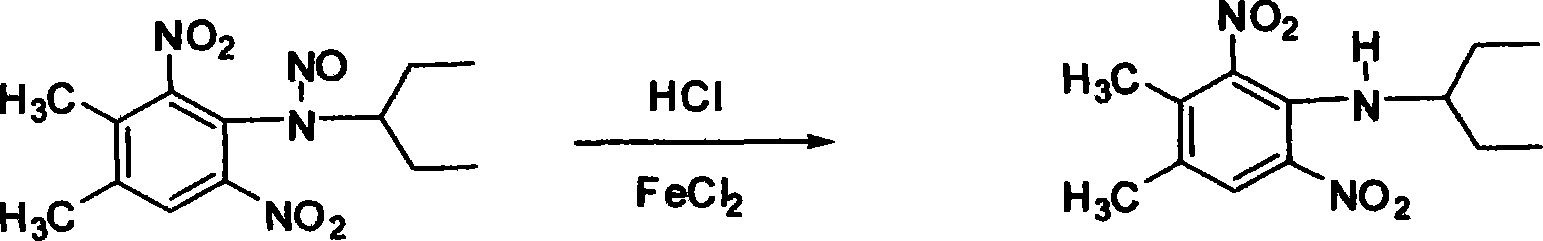

Method used

Image

Examples

Embodiment 1

[0031] 6g (0.02mol) of pendimethalin containing a certain amount of N-nitroso pendimethalin (content 30%) detected by HPLC was dissolved in 30g (24ml) of 1,2-dichloroethane, stirred Place it in a three-necked flask with a condenser, a thermometer and a stirring heating device, then add 12g of concentrated hydrochloric acid (10ml), gradually raise the temperature to 75°C, and react for 1h; then add 1.2g of FeCl 2 4H 2 O (0.006mol), continue to maintain 75 ° C for 3h, and then stop stirring. Sampling was detected by HPLC, and the content of N-nitrosodimethalin was lower than 100ppm.

[0032] Liquid chromatography analysis conditions: C18 column (150mm×4mm), mobile phase: acetonitrile: water = 80:20 (v / v), flow rate 1.0mL / min, detection wavelength 254nm, pendimethalin retention time is 5.93min , The retention time of N-nitroso pendimethalin was 3.36min, and the area was normalized and quantified (the same below).

Embodiment 2

[0034] 6g (0.02mol) is dissolved in 6g (5ml) 1, in 2-dichloroethane, starts Stir and place it in a three-necked flask with a condenser, a thermometer and a stirring heating device, then add 3g (2.5ml) of concentrated hydrochloric acid, gradually raise the temperature to 75°C, and react for 1h; then add 0.3g of FeCl 2 4H 2 O (0.0015mol), continue to keep the reaction at 75°C for 3h and then stop stirring, take a sample and detect it by HPLC, the content of N-nitrosodimethalin is less than 100ppm. (analysis method is with embodiment 1).

Embodiment 3

[0036] 6g (0.02mol) of pendimethalin containing a certain amount of N-nitroso pendimethalin (content 30%) detected by HPLC was dissolved in 60g (47.7ml) of 1,2-dichloroethane, Start stirring and place it in a three-necked flask with a condenser, a thermometer and a stirring heating device, then add 15g (12.6ml) of concentrated hydrochloric acid, gradually raise the temperature to 75°C, and react for 1h; then add 6g of FeCl 2 4H 2 O (0.03mol), continue to maintain 75 ° C for 3h, and then stop stirring. Sampling was detected by HPLC, and the content of N-nitrodimethalin was lower than 100ppm. (analysis method is with embodiment 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com