Alloy tool steel in multi-type super-fine carbonates

A technology of alloy tool steel and carbide, which is applied in the field of tool and die steel, can solve the problems of difficult carbide refinement, decreased hardness, lack of high-carbon medium-alloy steel varieties, etc., and achieve high sharpness, high hardness, and high wear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

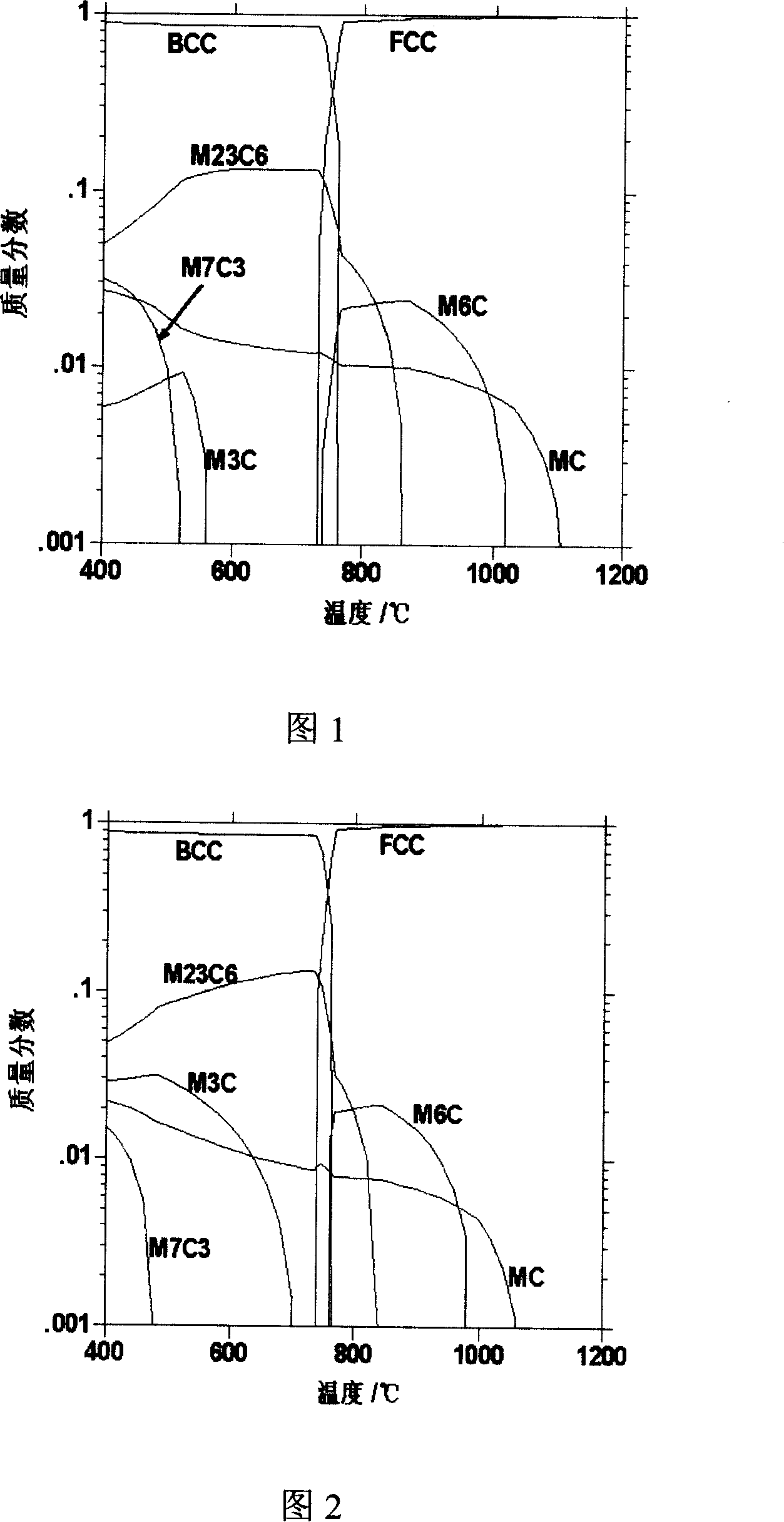

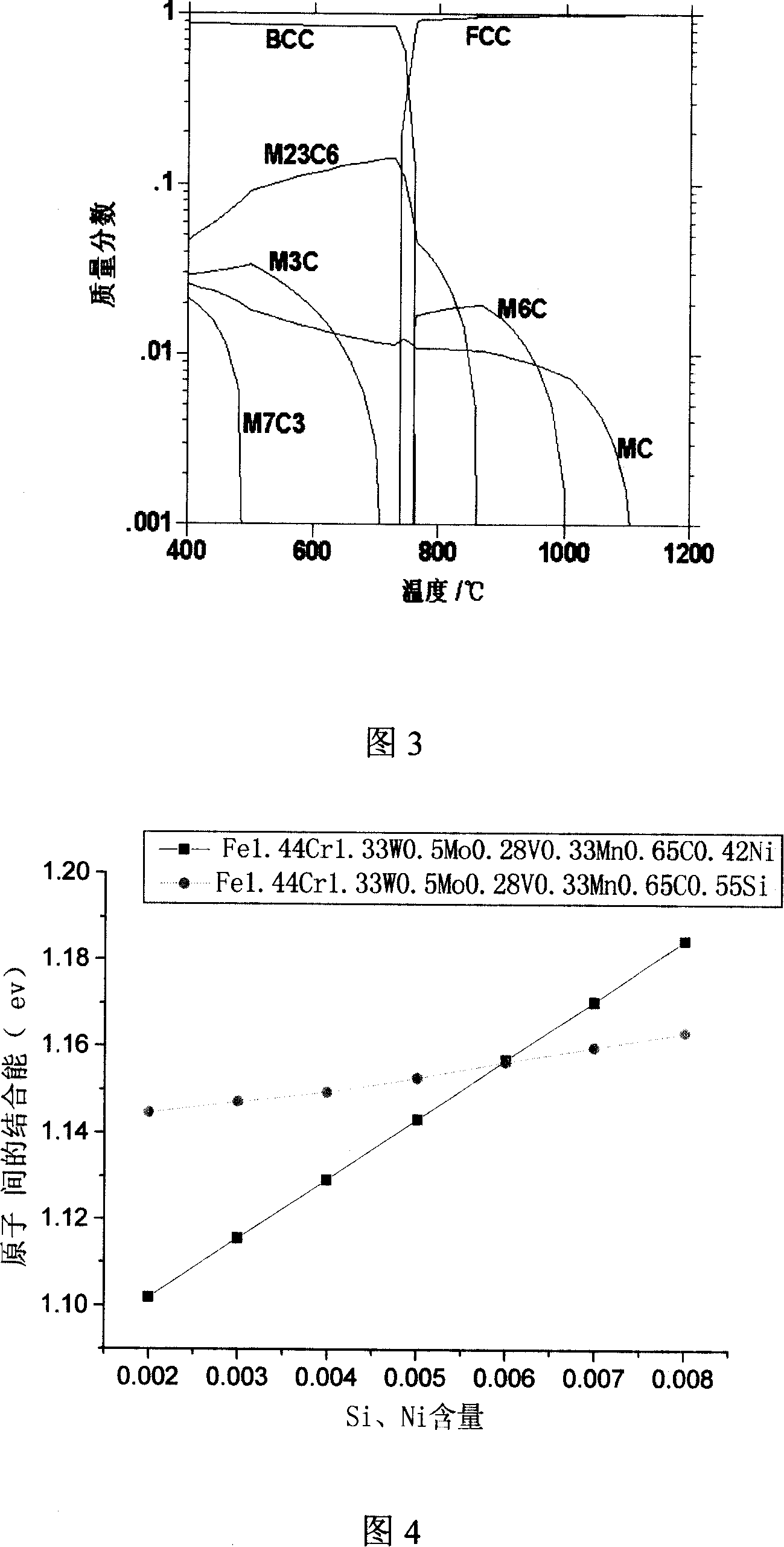

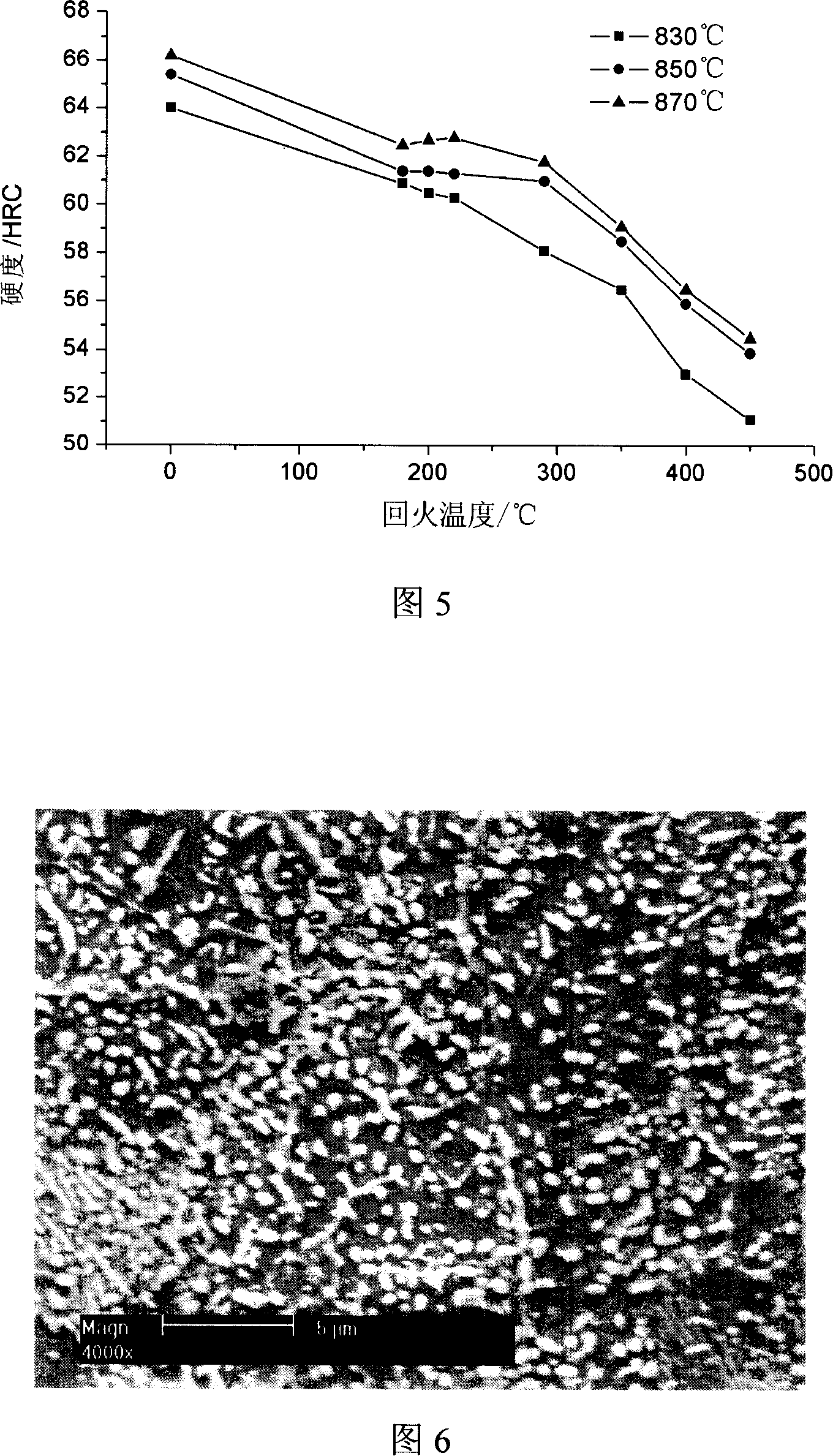

[0022] A multi-type ultra-fine carbide medium alloy tool steel as shown in Figures 1 to 3. The composition and content are shown in Table 1, the heat treatment process is shown in Table 2, and the mechanical properties are shown in Table 3. The manufacturing process route of molds and cutting tools is: forging→annealing→straightening→rough grinding→quenching→straightening→(cold treatment)→tempering→straightening→grinding→finished product.

[0023] Table 1 Ingredients

[0024] C

Si

mn

Cr

W

Mo

V

Ni

S

P

Fe

0.76-

0.85

0.45-

0.6

0.25-

0.45

1.7-2.

1

1.7-1.

95

0.9-1.

05

0.3-0.

4

0.25-0.

6

≤0.015

≤0.02

margin

[0025] Table 2 heat treatment process

[0026] work

Preface

Process and description

Organization and Notes

retreat

fire

Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com