Linear motor accelerated impact spring fatigue test device

A linear motor, fatigue test technology, applied in the direction of impact test, measuring device, machine/structural component test, etc., can solve the problem that the vibration frequency and amplitude range cannot reach a large value at the same time, the impact force and speed cannot meet the actual needs, Small amplitude and other problems, to achieve the effect of simple structure, easy operation, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments.

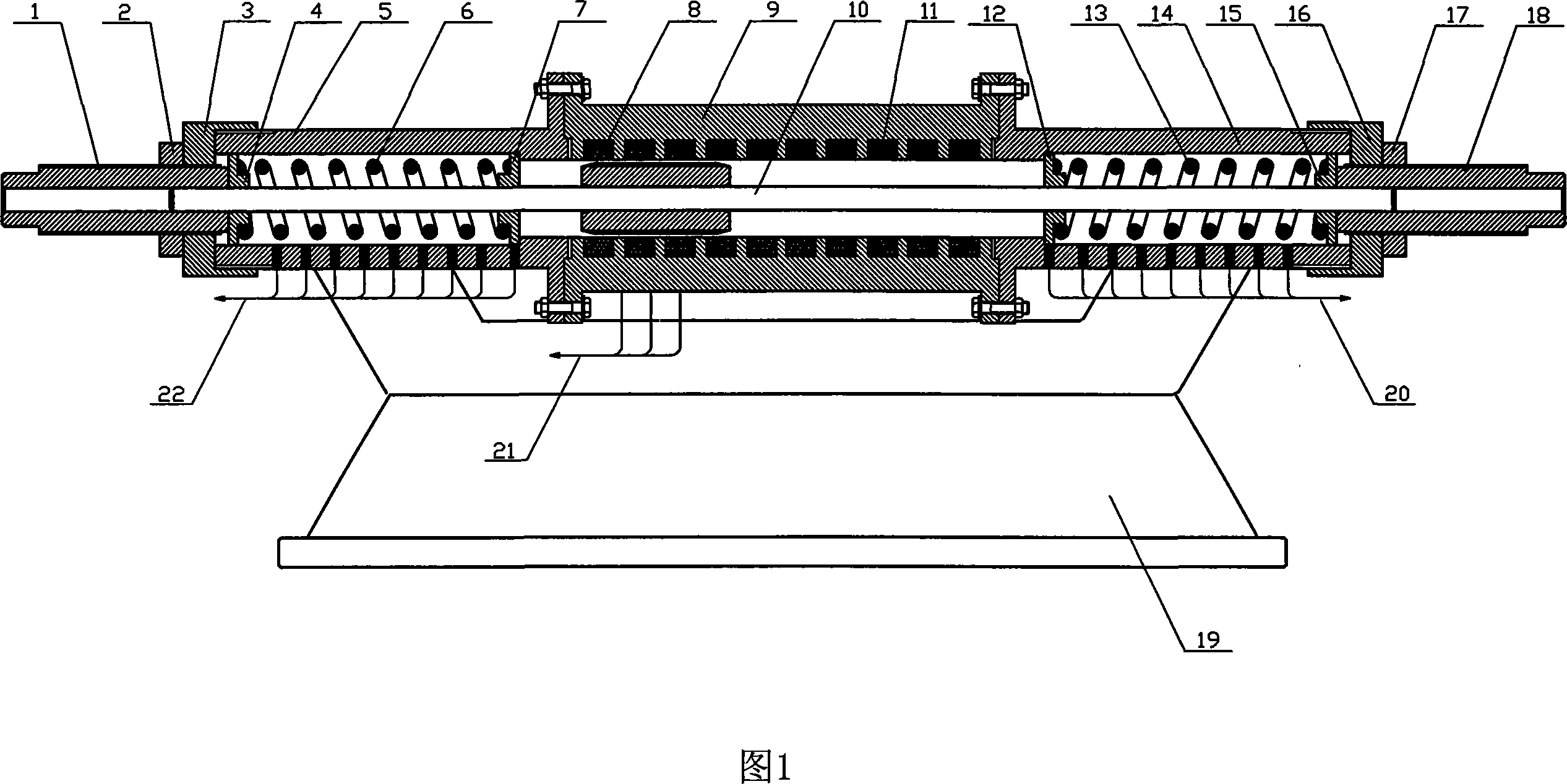

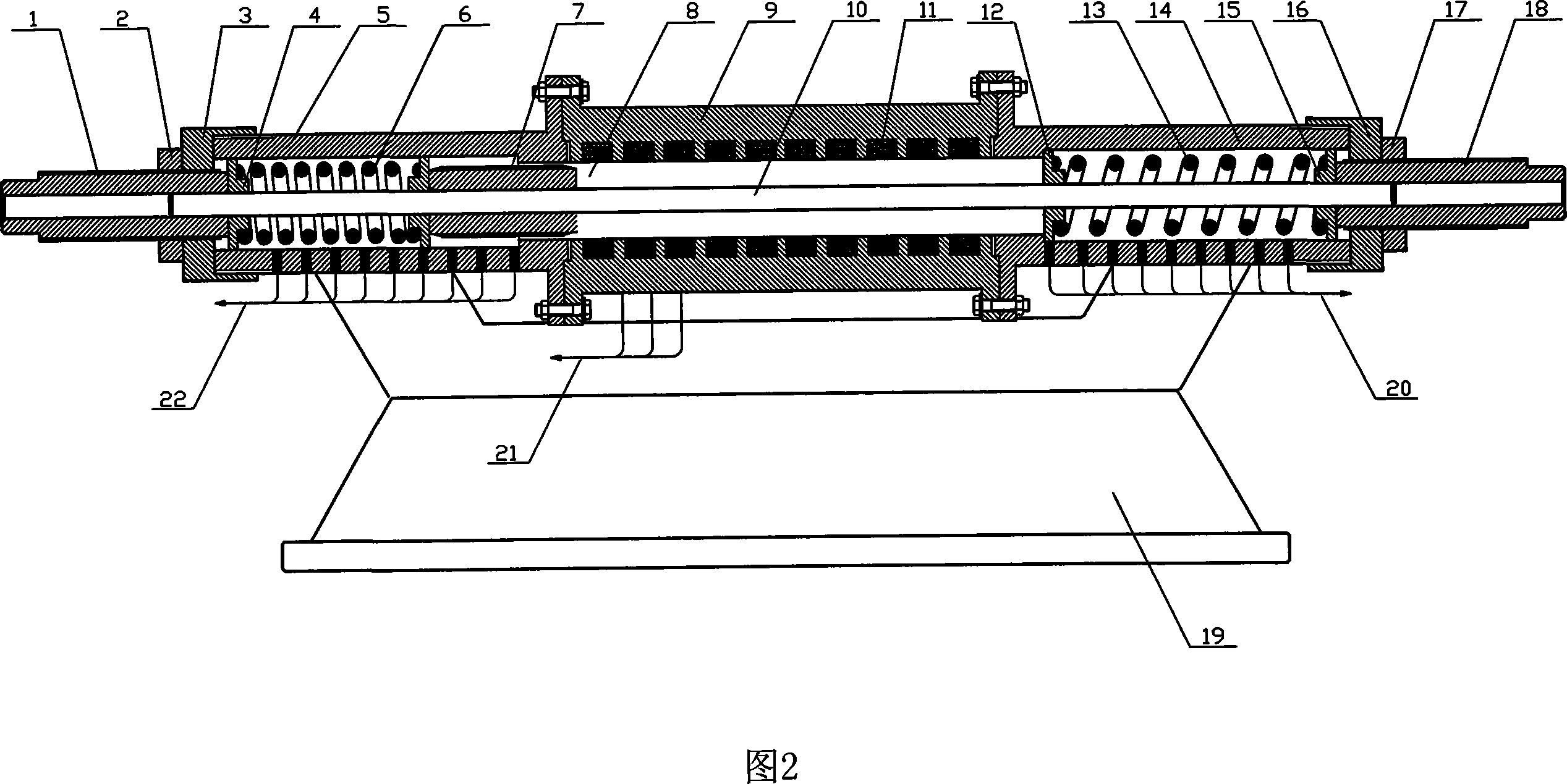

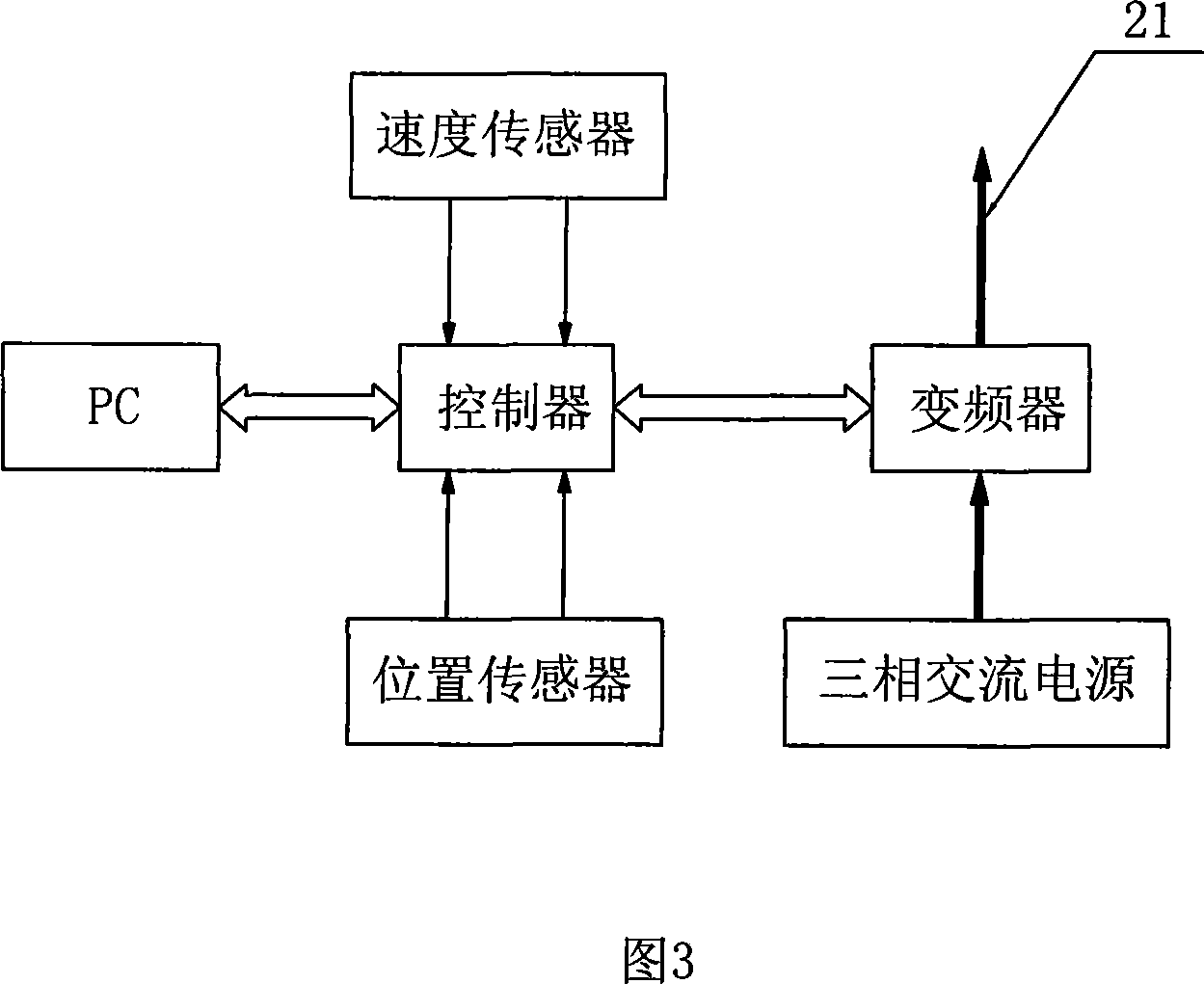

[0024] As shown in Figures 1 to 3, a linear motor accelerated impact spring fatigue test device mainly includes a cylindrical linear motor, an electrical control part and a fuselage. Among them, the cylindrical linear motor is mainly composed of primary 9 (including winding 11) and secondary 8; the electrical control part mainly includes three-phase AC power supply, frequency converter, 2 speed sensors and 2 sets of position sensors, etc.; the fuselage mainly Including machine base 19, 2 adjusting screws 1, 18, 2 lock nuts 2, 17, 2 nuts 3, 16, 2 rear baffles 4, 15, 2 jackets 5, 14, 2 front baffles 7,12 and guide bar 10 etc.

[0025]2 adjusting screws 1, 18, 2 lock nuts 2, 17, 2 nuts 3, 16, 2 rear baffles 4, 15, 2 outer jackets 5, 14 and 2 front baffles 7, 12 is horizontally symmetrically installed on the support 19, and the support 19 is affixed to the ground and is the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com