Particles for display media and information display panel using the particles

A display medium and information display technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of complex structure, charge injection, lack of stability, etc., and achieve excellent durability, high heat resistance, and excellent display quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

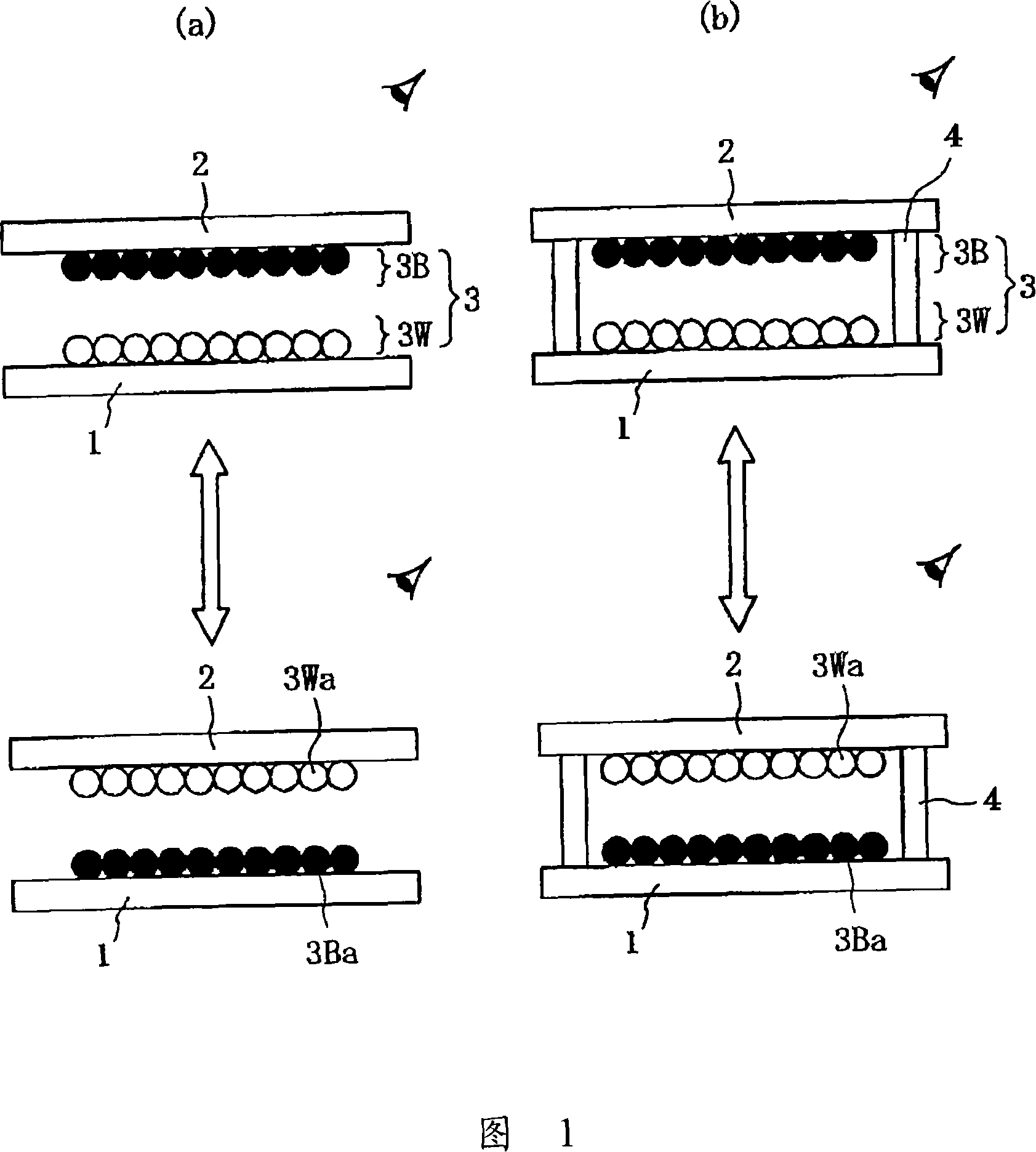

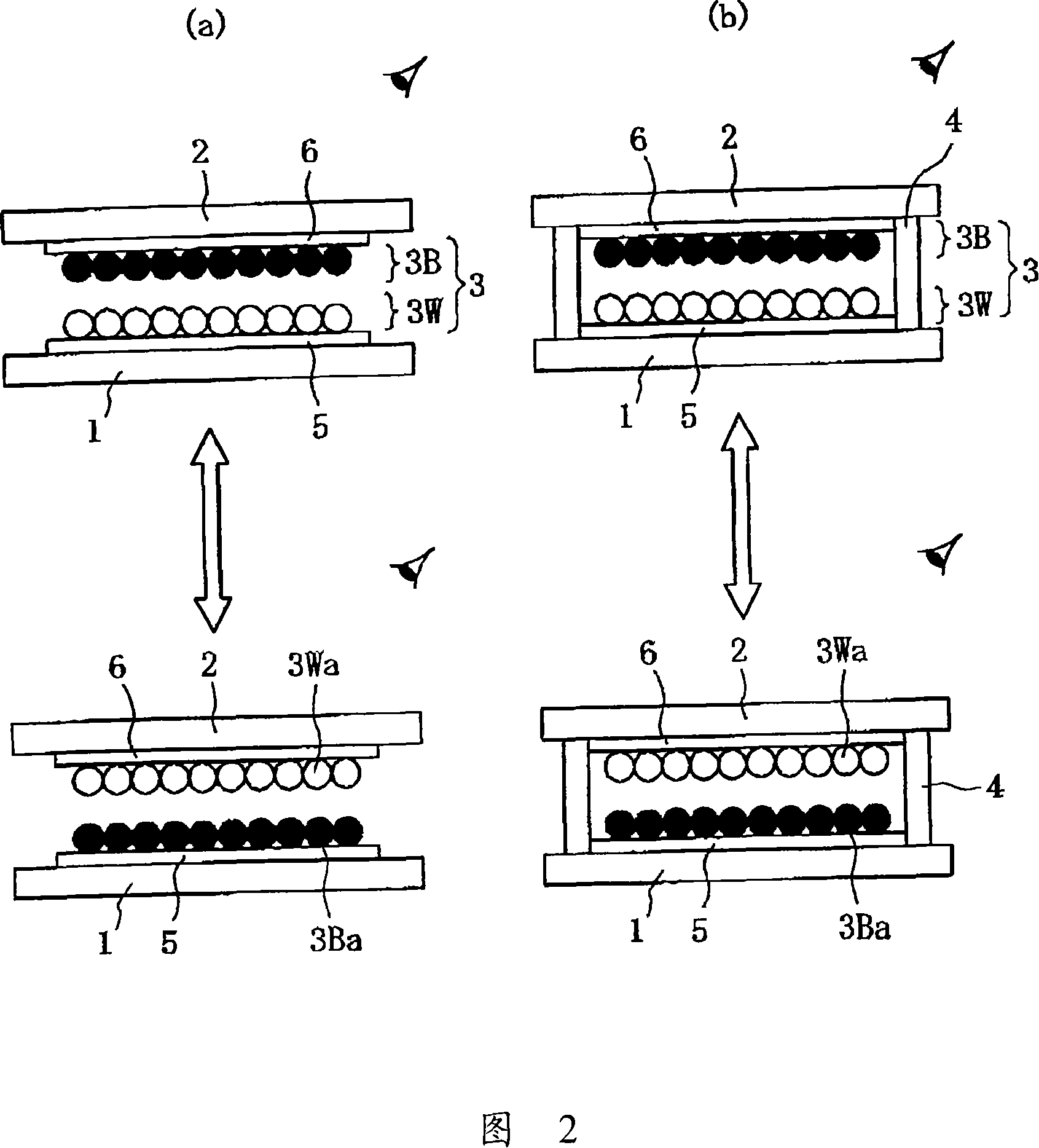

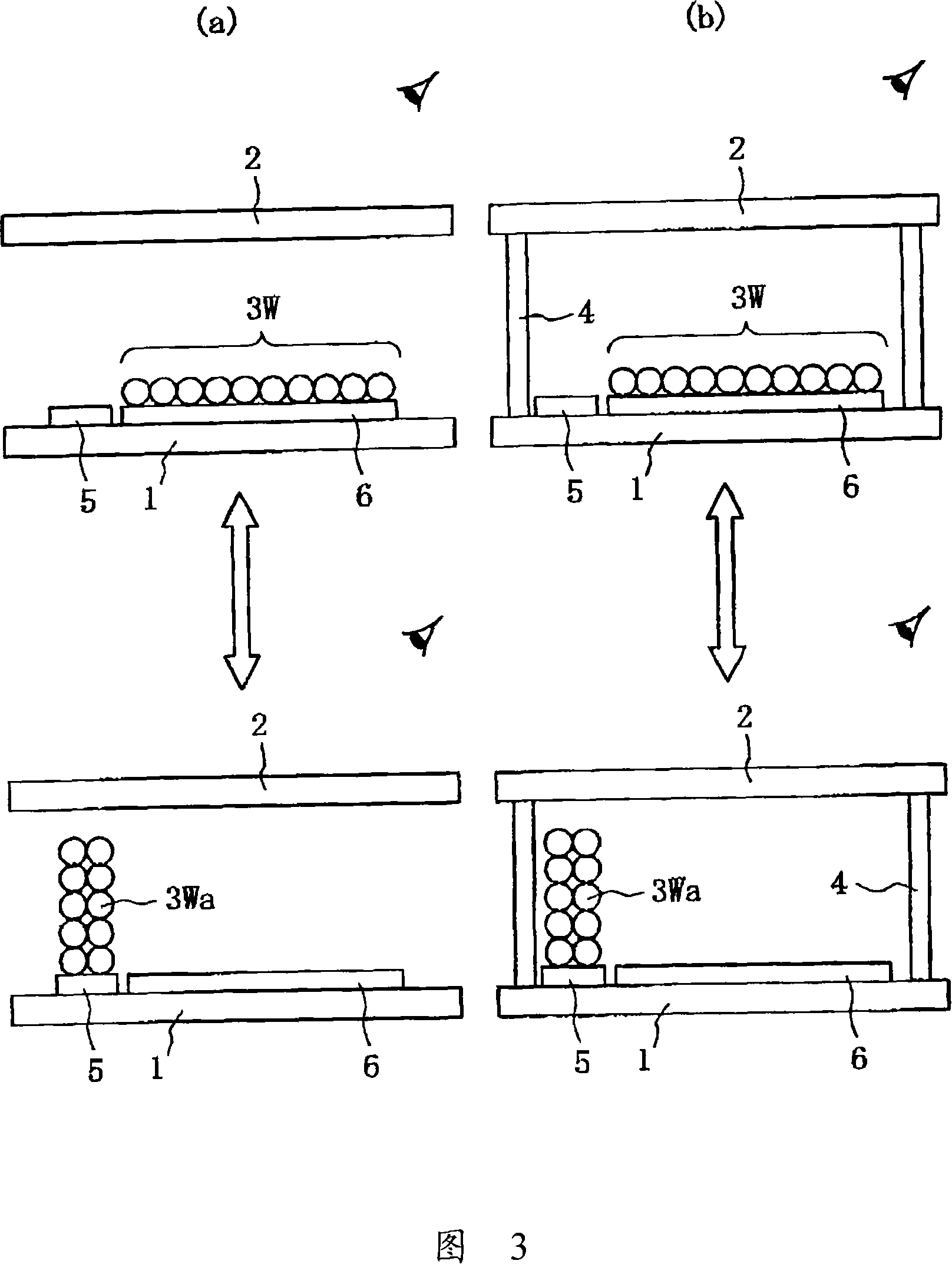

Method used

Image

Examples

Embodiment 1

[0094] As particles for black display media, 3 parts by weight of aniline black compound (BONTRON N07: produced by Orient Chemical Industries, Ltd.) as a positively charged charge control agent and 5 parts by weight of carbon black as a black colorant were made by a sand mill. (Special Black5: produced by Degussa) was dispersed in 60 parts by weight of methyl methacrylate (Kanto Chemical Chemicals) and 40 parts by weight (about 25 mol%) of ethyl as a polyfunctional monomer having a plurality of polymerizable reactive groups in one molecule. In diol dimethacrylate (Wako Pure Chemical Chemicals), make 5 parts by weight of (acrylic and methacrylic) resin-(acrylic and methacrylic with hydrocarbon or fluorinated hydrocarbon in the side chain) resin Block copolymer (MODIPER F600: produced by NOF, fluorocarbon component C 8 f 17 ) was dissolved, and then 2 parts by weight of lauryl peroxide (PEROYL L: produced by NOF) was dissolved, and the resulting solution was suspended in sodium...

Embodiment 2

[0098] Except that in Example 1, when manufacturing the particles for white display media, 50 parts by weight of cycloolefin resin (ZEONEX 330R: produced by ZEON Corporation) and 50 parts by weight of cycloolefin resin (ZEONOR 1410R: produced by ZEON Corporation) were mixed, and the above-mentioned implementation The particles W1 for white display media of Example 1 were carried out in the same manner to produce particles W2 for white display media. Table 1 shows the properties of the resin itself and the properties of the particles W2 for white display media.

Embodiment 3

[0100] Except using cycloolefin resin (ZEONEX 480R: produced by ZEON Corporation) instead of cycloolefin resin (ZEONEX 330R: produced by ZEON Corporation) in Example 1, the same procedure as the particles W1 for white display media in Example 1 above was used to produce a white display medium Use particle W3. Table 1 shows the properties of the resin itself and the properties of the particles W3 for white display media.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com