Digital sun sensor calibration method and device

A sun sensor and calibration method technology, which is applied in the direction of measuring devices, photometry, and sunlight measurement, can solve the problems of internal model parameter errors, calibration method errors, and sun sensor installation deviations, etc., to achieve easy implementation, Easy to operate and improve the effect of calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

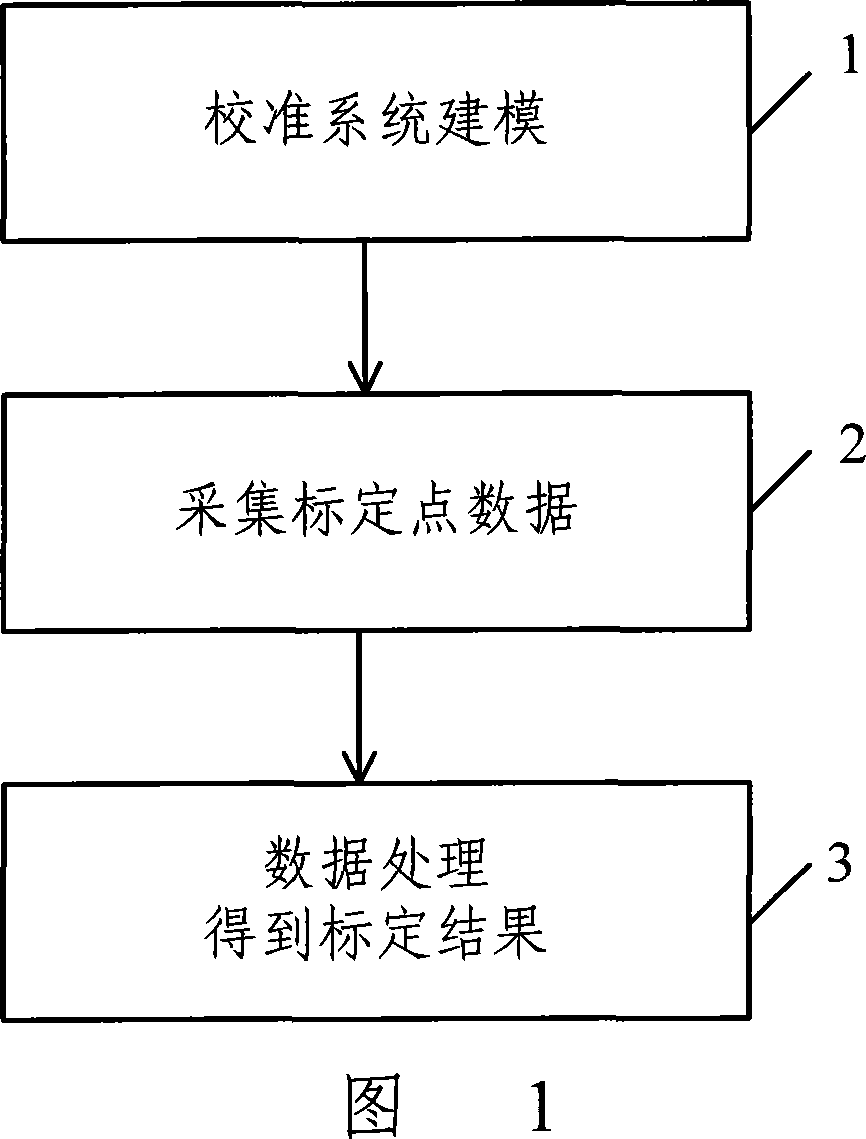

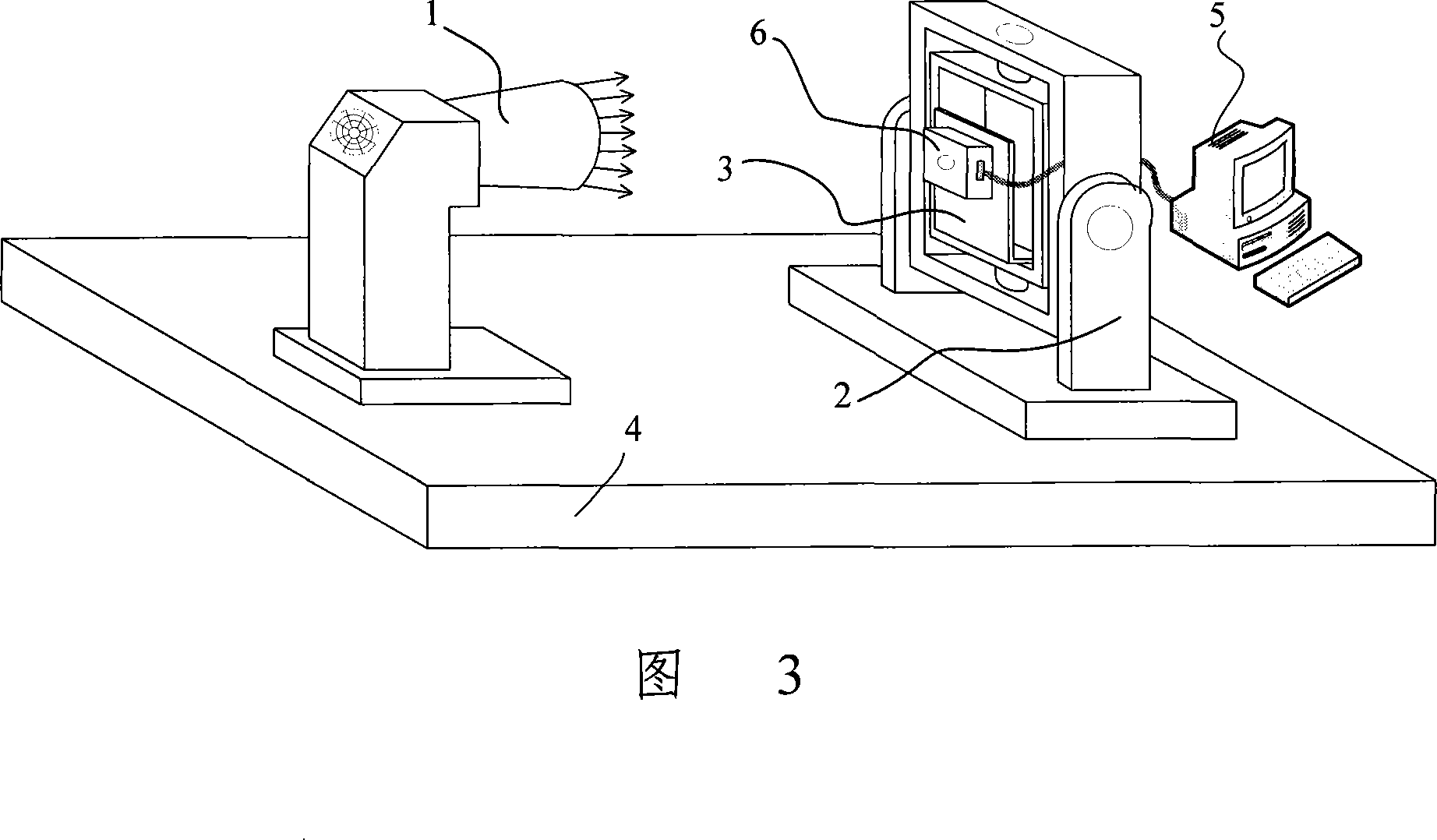

[0030] The basic idea of the present invention is: by establishing a unified mathematical model of solar sensor imaging internal and external parameters, factors such as the installation error of the solar simulator, the installation error of the sun sensor on the two-axis turntable, the installation error and distortion of the optical mask are considered in a unified manner , using a two-step method to calibrate the parameters involved, which improves the calibration accuracy.

[0031] The present invention adopts the method for unified modeling of internal and external parameters to the establishment of solar sensor imaging mathematical model, and concrete steps are:

[0032] Step 1: According to the external parameters and internal parameters of the solar sensor calibration system, a unified model of solar sensor imaging is established.

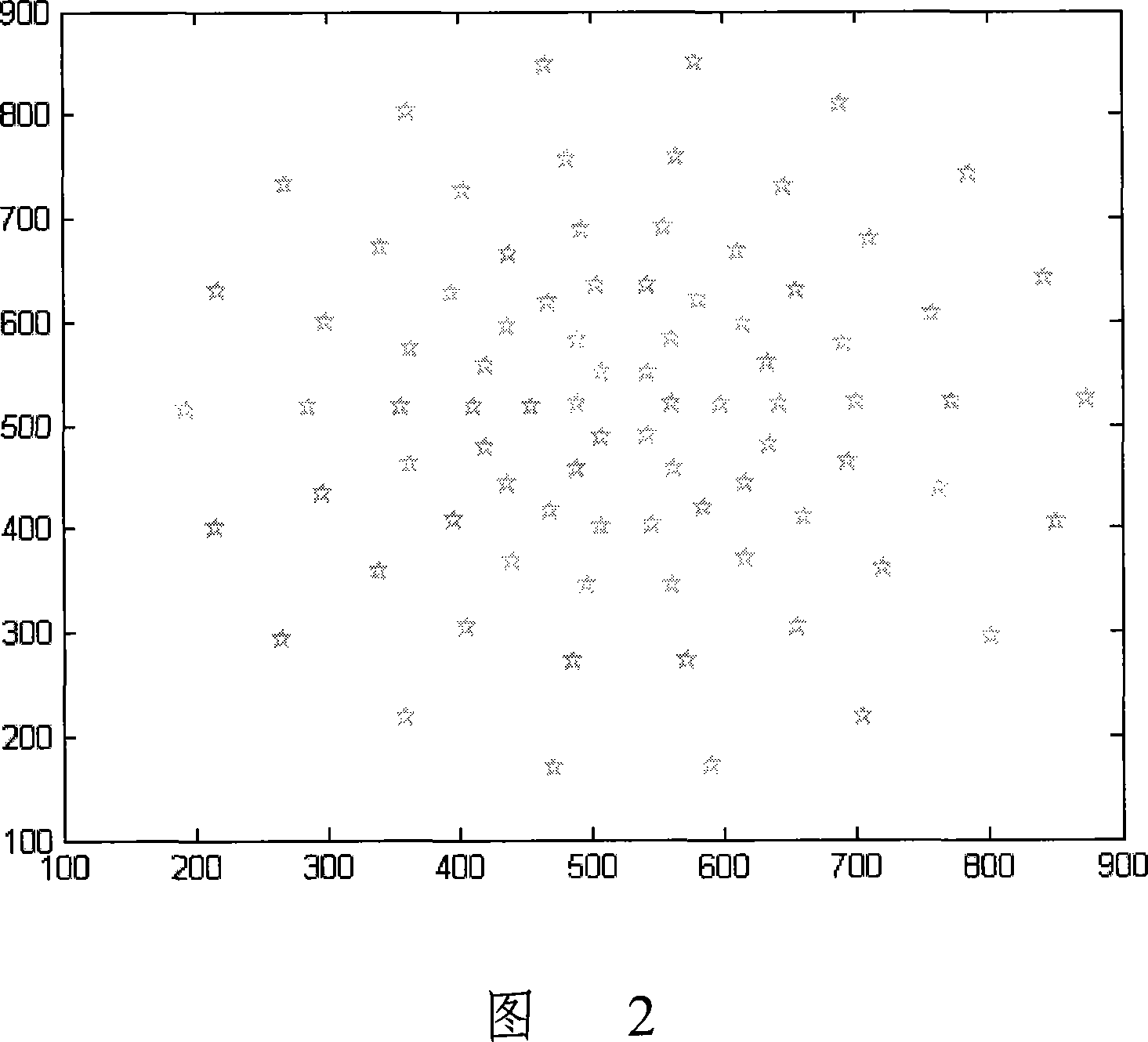

[0033] Step 101: Establish a coordinate system.

[0034] When describing the external parameter modeling method, at first illustrate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com