Methodc for preparing sub-micron gemfibrozil medicament powder

A gemfibrozil and submicron technology is applied in the field of preparing submicron ultrafine gemfibrozil pharmaceutical powder by a reactive crystallization method, and can solve the problems of large amount of surfactant and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

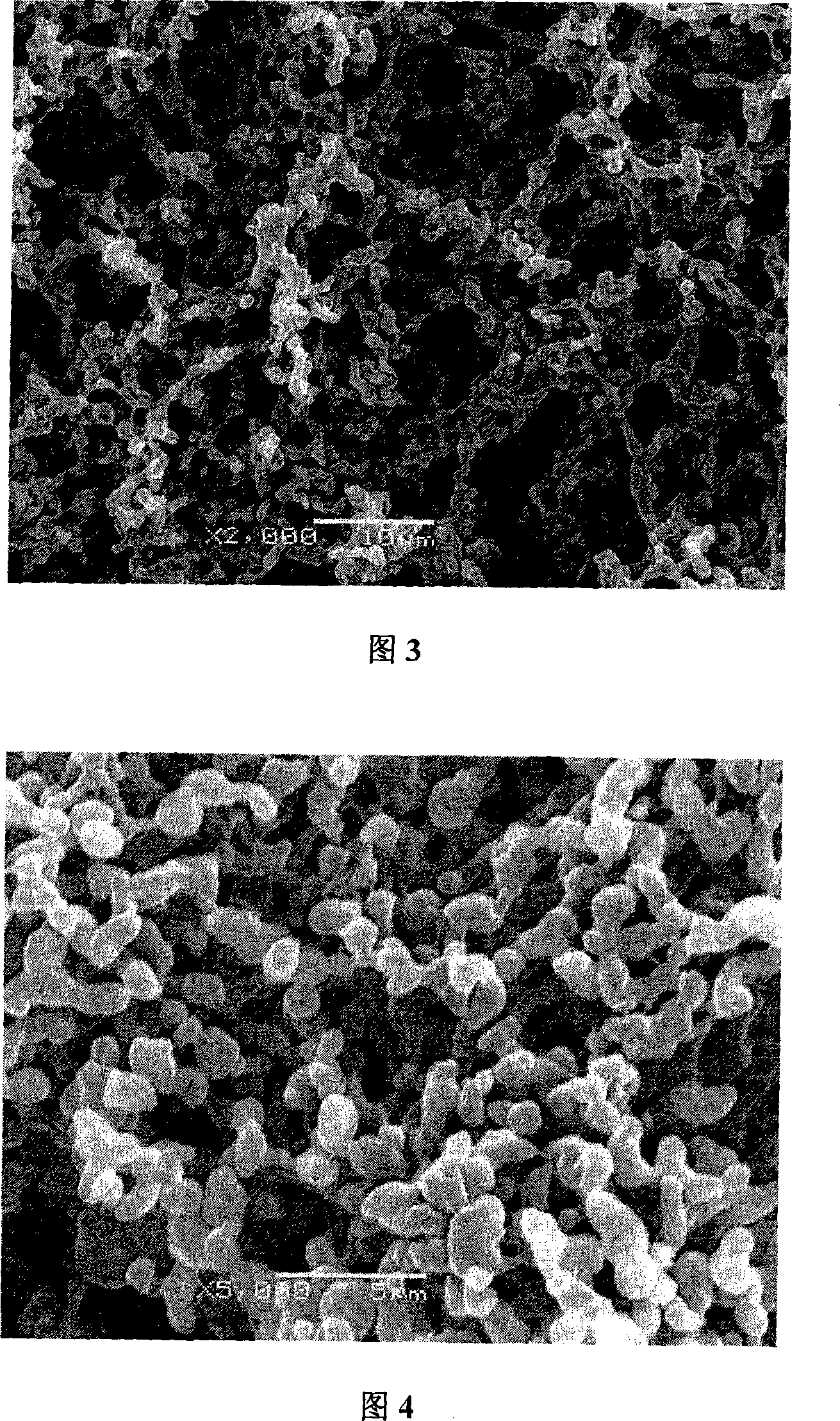

[0034] Weigh 0.16g of polyvinylpyrrolidone K30 and dissolve it in 100ml of aqueous hydrochloric acid solution with a concentration of 0.25mol / L. After it is completely dissolved, pour it into a reaction kettle and stir at a speed of 1000rpm. Then weigh 3.0 g of the gemfibrozil bulk drug and dissolve it in 100 ml of aqueous sodium hydroxide with a concentration of 0.15 mol / L to obtain a gemfibrozil bulk drug solution. The obtained bulk drug solution was quickly added into the reaction kettle, and the gemfibrozil drug was reacted and crystallized at 20° C. to obtain a suspension of gemfibrozil drug particles, and the stirring was continued for 30 minutes. Then filter and rinse the filter cake with deionized water. The obtained filter cake was put into a forced air drying oven at 40° C. to dry for more than 3 hours to obtain the dried gemfibrozil drug powder. Observation with electron scanning electron microscope, as shown in the scanning electron microscope photo in Figure 2, t...

Embodiment 2

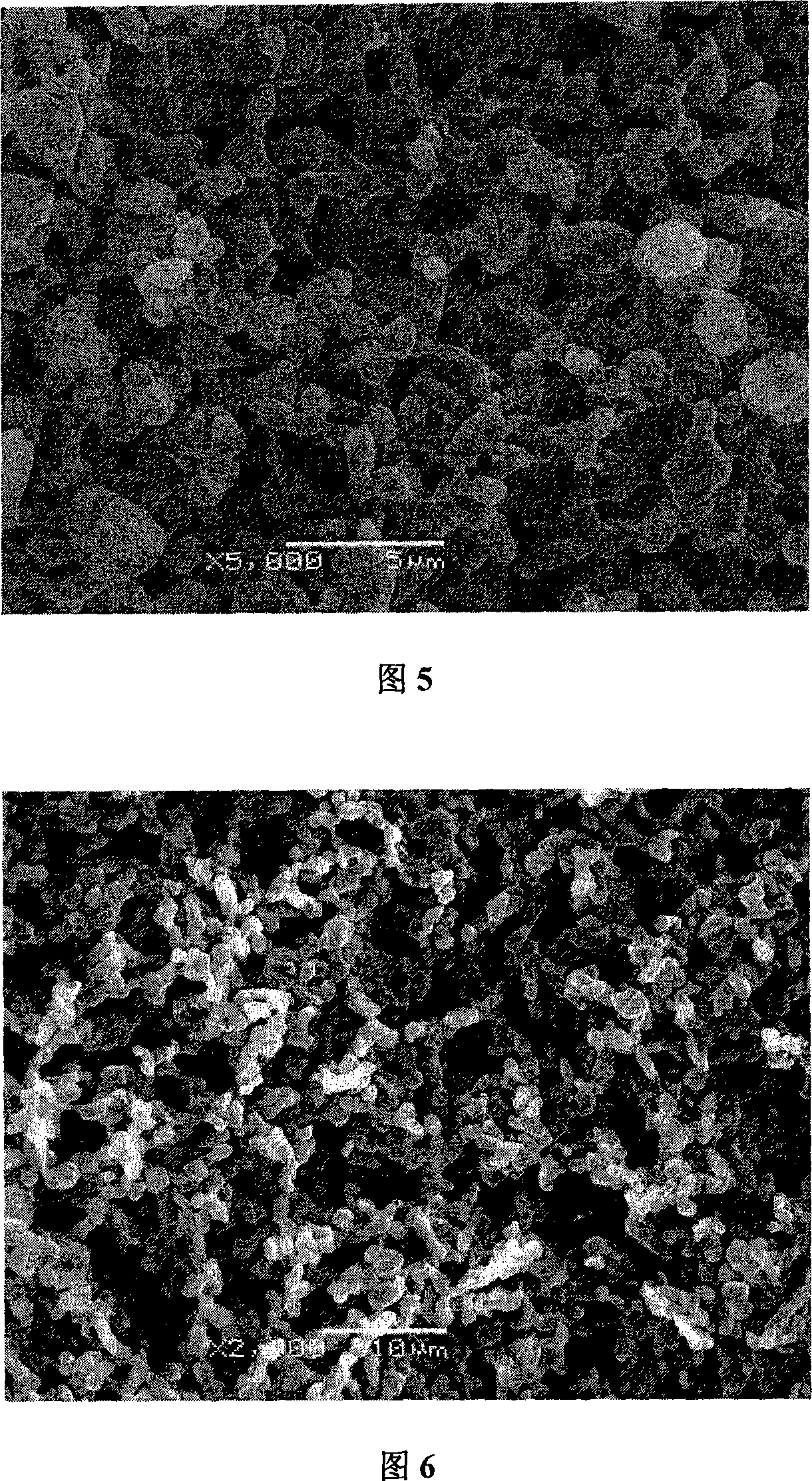

[0036] Weigh 0.15 g of methylcellulose and dissolve it in 100 ml of aqueous hydrochloric acid solution with a concentration of 0.25 mol / L. After it is completely dissolved, pour it into a reaction kettle and stir at a speed of 10,000 rpm. Then weigh 3.0 g of the gemfibrozil bulk drug and dissolve it in 100 ml of aqueous sodium hydroxide with a concentration of 0.15 mol / L to obtain a gemfibrozil bulk drug solution. Quickly add the obtained raw material drug solution into the reaction kettle, so that the gemfibrozil drug is reacted and crystallized at 18° C. to obtain a suspension of gemfibrozil drug particles, continue to stir and age for 30 minutes, then filter, and use deionized water Rinse filter cake. Put the obtained filter cake into a beaker, add water with a weight equivalent to 5 times the weight of the wet filter cake, and redisperse the filter cake in water under the action of ultrasound to obtain a uniform suspension. The resulting suspension was poured into liquid ...

Embodiment 3

[0038] Weigh 0.39g of methylcellulose and dissolve it in 500ml of aqueous hydrochloric acid solution with a concentration of 0.05mol / L. After it is completely dissolved, pour it into a reaction kettle and stir at a speed of 2000rpm. Then weigh 2.6g of the gemfibrozil bulk drug and dissolve it in 100ml of sodium hydroxide solution with a concentration of 0.10mol / L to obtain the gemfibrozil bulk drug solution. Quickly add the obtained raw drug solution into the reaction kettle, make the gemfibrozil drug react and crystallize at 20° C. to obtain a suspension of gemfibrozil drug particles, continue to stir and age for 30 minutes, then filter, and use deionized water Rinse filter cake. The obtained filter cake is put into a quick drying apparatus for drying to obtain dry gemfibrozil drug powder. Observed by scanning electron microscope, gemfibrozil drug particles are spherical, with a particle size of 500nm-2μm and a narrow particle size distribution, as shown in the scanning elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com