Cutting method for wafer

A cutting method and wafer technology, applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of high price, insufficient cleaning effect, and decline in the quality of semiconductor chips, and achieve the effect of inhibiting corrosion and maintaining the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, a wafer cutting method as the best mode for carrying out the present invention will be described with reference to the drawings.

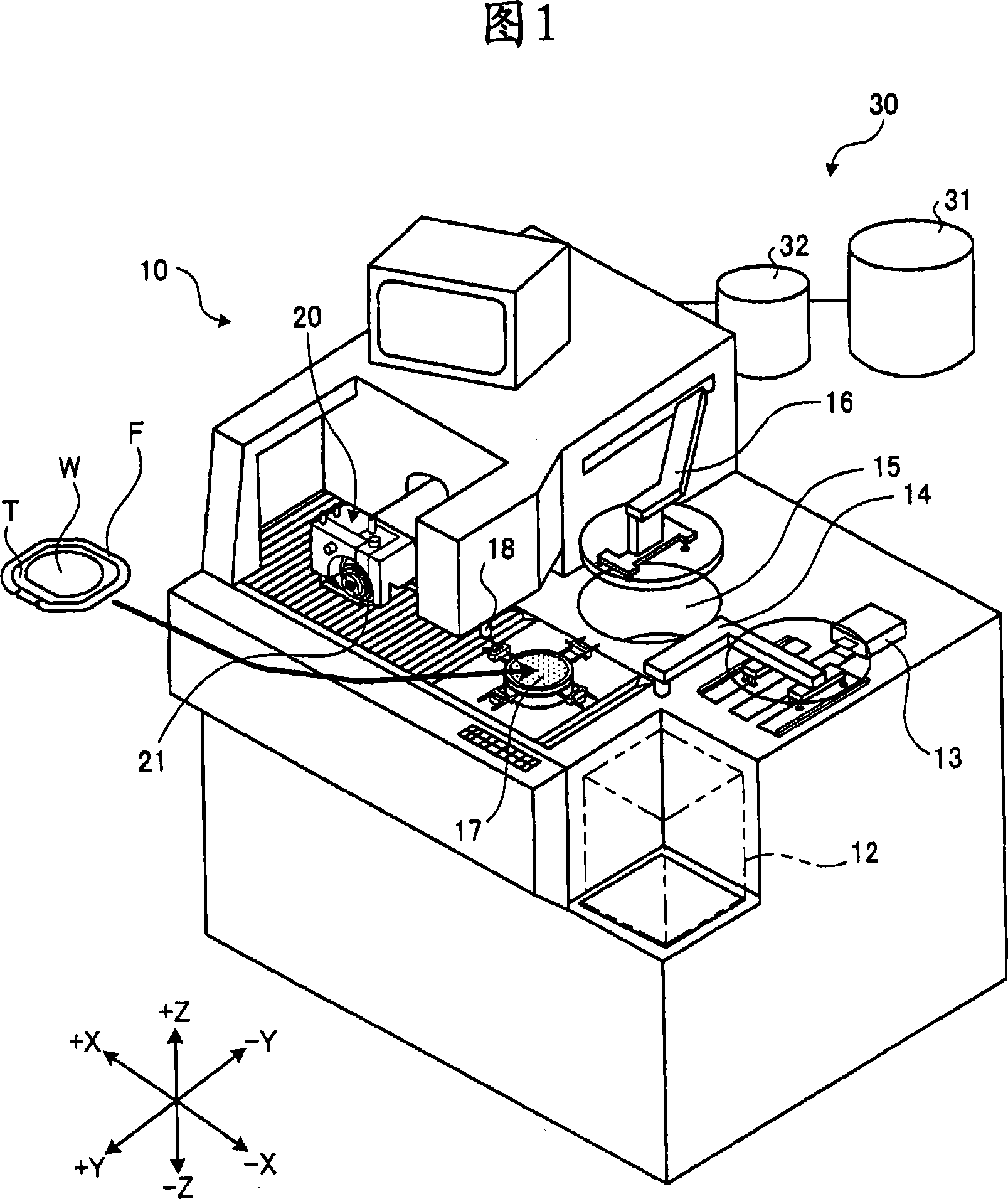

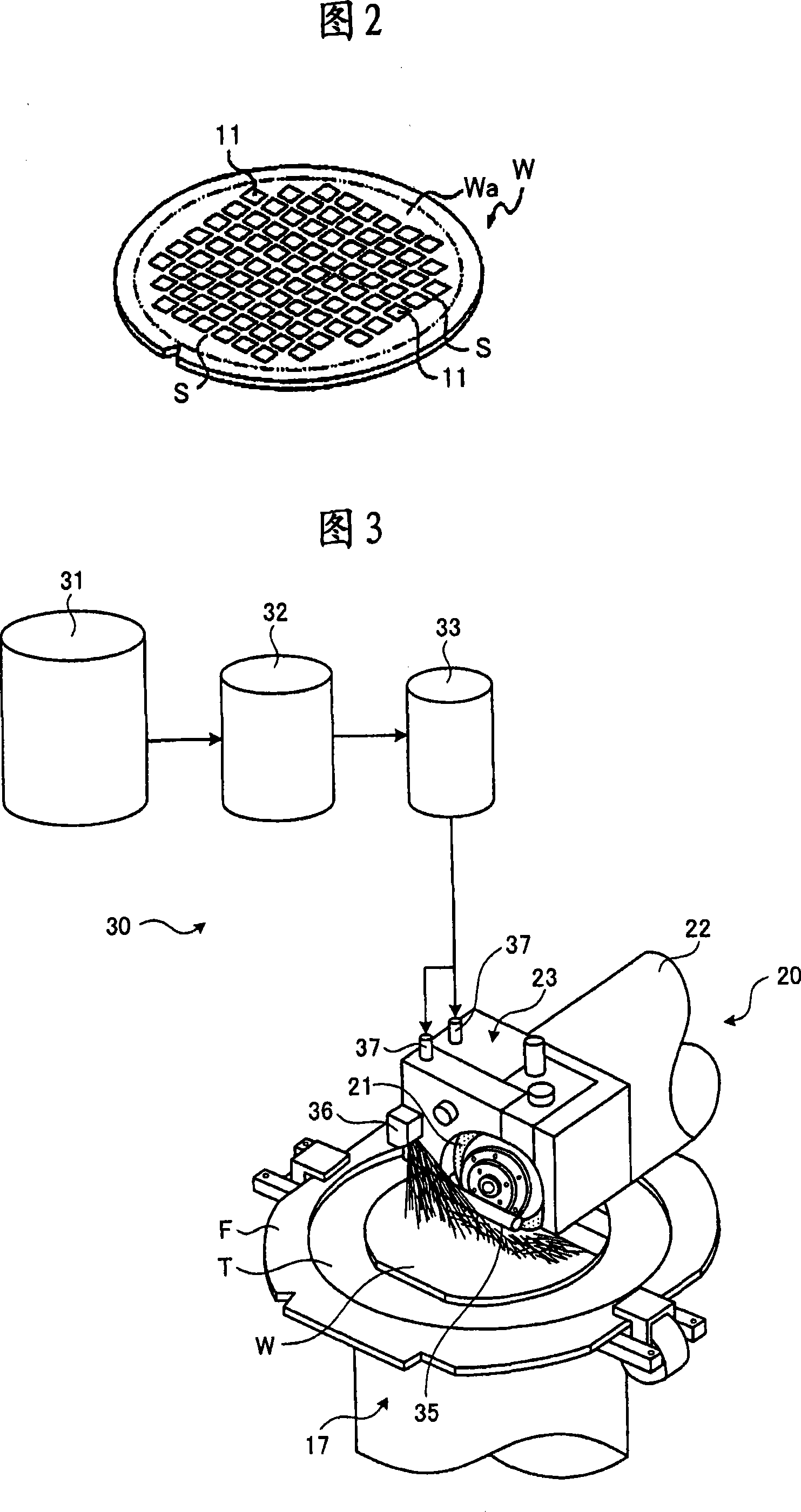

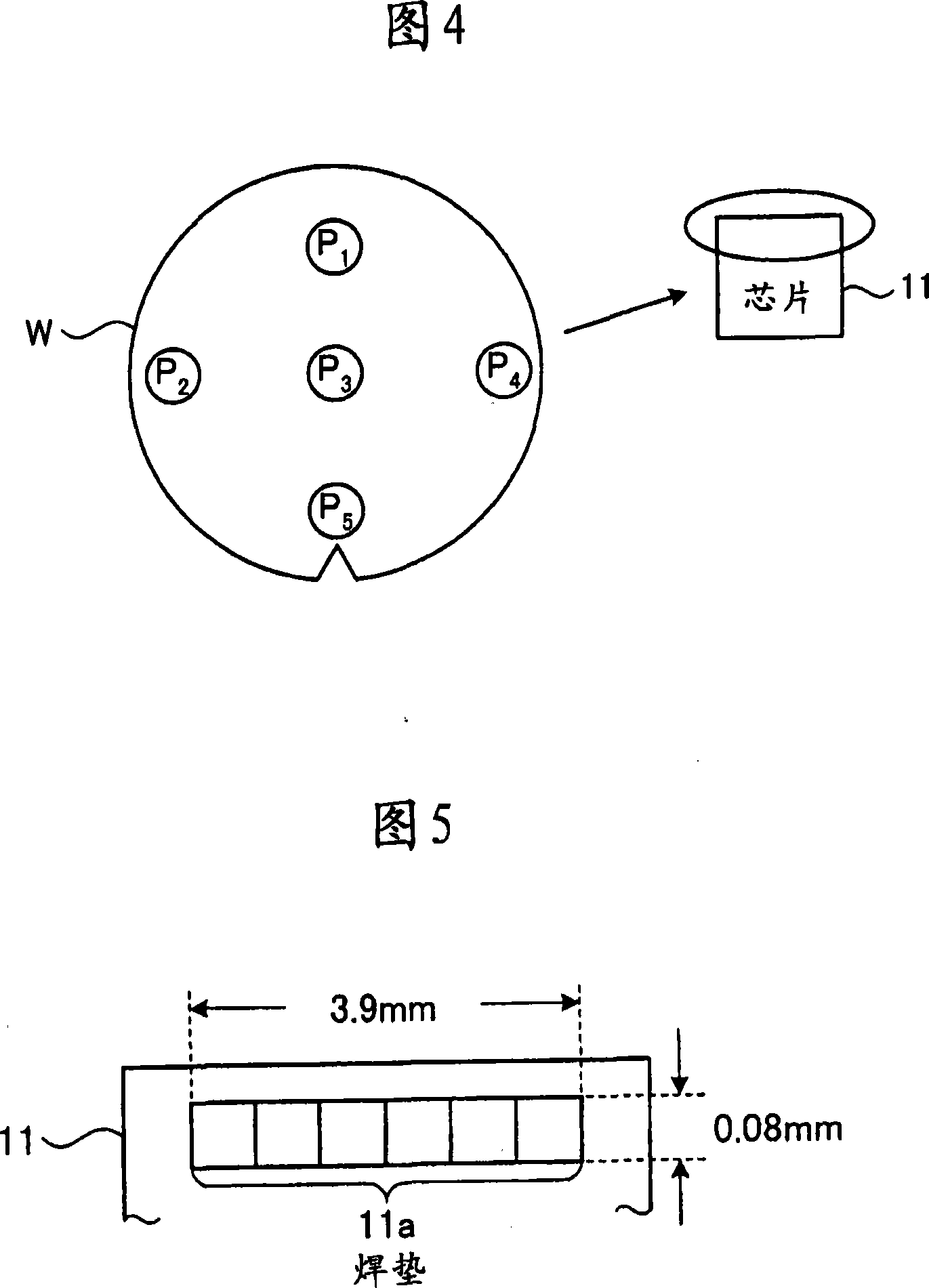

[0022] 1 is a schematic perspective view showing a configuration example of a cutting apparatus for carrying out a wafer cutting method according to an embodiment of the present invention, FIG. 2 is a perspective view showing a configuration example of a wafer applied to this embodiment, and FIG. A perspective view of a configuration example of a cutting water supply device. The cutting device 10 has a transport device 13, a transport device 14, a cleaning device 15, and a transport device 16. At the same time, it has a chuck table 17 integrally formed with the frame F to hold the wafer W, a camera 18 for alignment, and a chip holder for cutting. A cutting device 20 for wafer W on chuck table 17 and a cutting water supply device 30 for supplying cutting water to wafer W are provided.

[0023] First, the wafer W is pasted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com