Method for producing sintering plate-like corundum by ultra-high temperature shaft kiln

A process method and tabular corundum technology are applied in the field of preparation of basic refractory materials, which can solve the problems such as few public reports on tabular corundum production methods and no tabular corundum process methods, and can achieve increased density, increased density, Not easy to layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

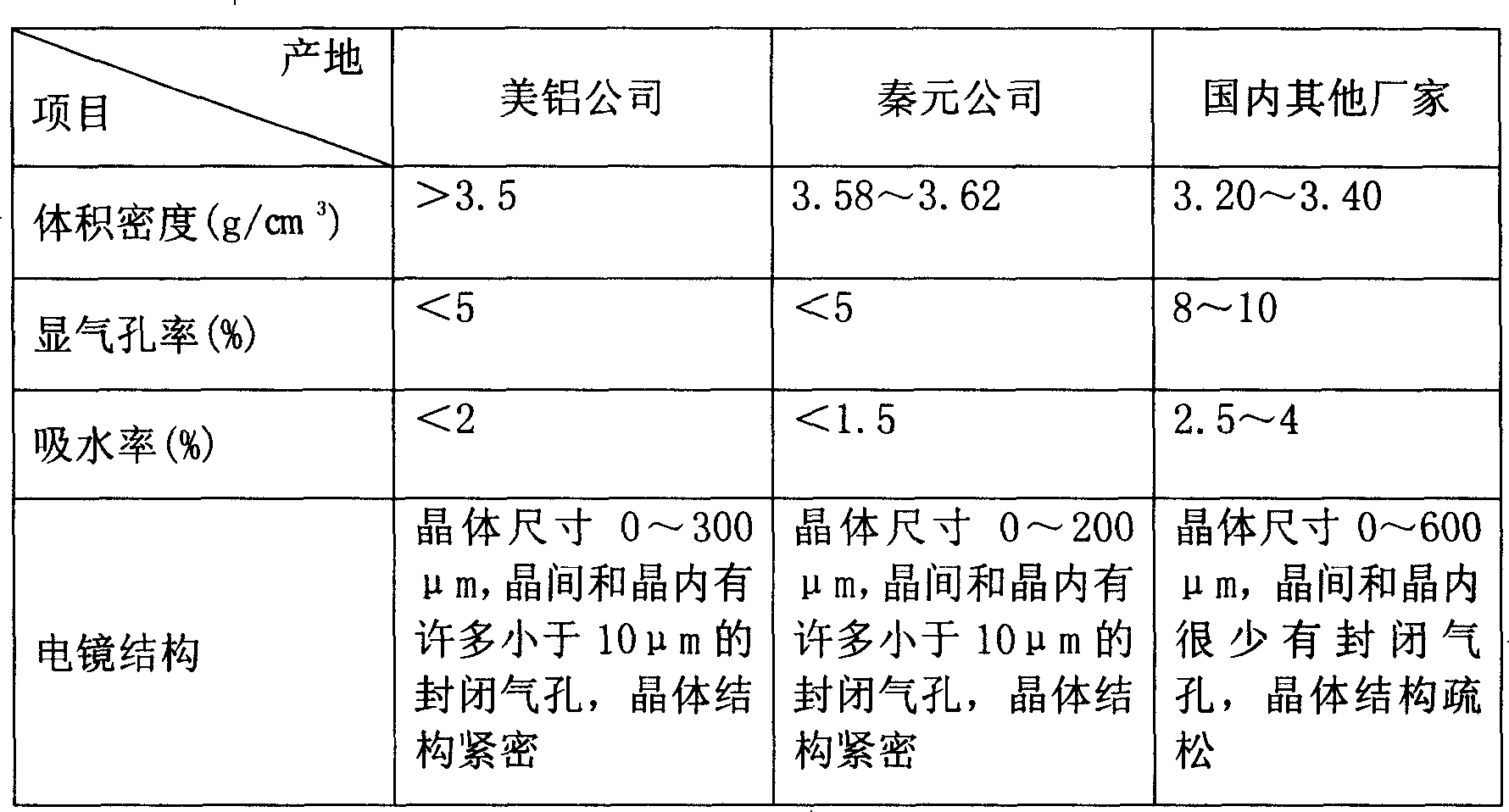

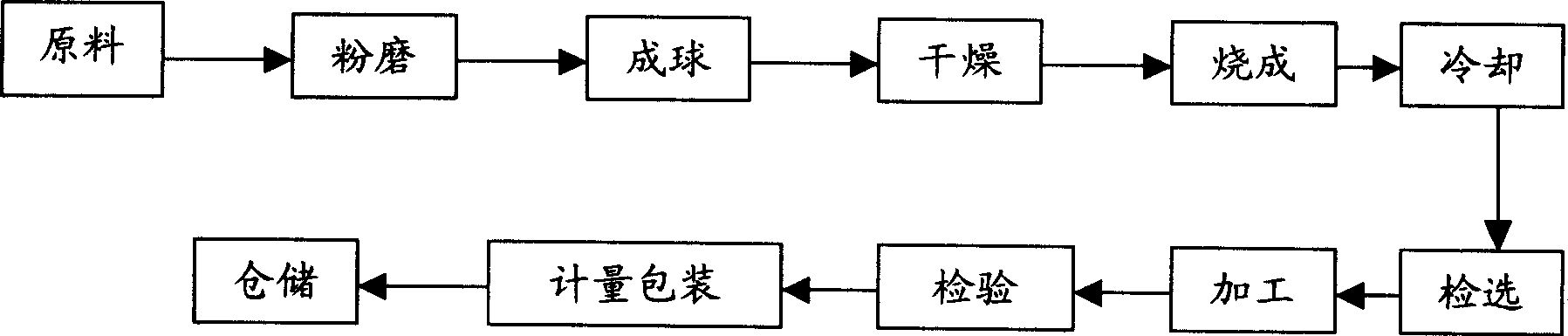

[0026] Overall process flow of the present invention is:

[0027]

[0028] The specific steps are:

[0029] Step 1: Raw material selection

[0030] Choose low-sodium high-purity calcined alumina powder as raw material, and its chemical index should meet: Al 2 o 3 >98.5%, Na 2 O2 2 o 3 <0.05%.

[0031] Step 2: Grinding

[0032] Put the above raw materials into the vibrating grinder for grinding. The grinding machine is made of alumina corundum lining and corundum grinding balls. The vibrating grinder is equipped with an airflow classifier. The fineness of the fine powder is controlled by adjusting the speed of the classifier, requiring φ The content of fine powder <10μm is greater than 95%, and then sent into the pulse dust collector by wind for ball formation.

[0033] Step Three: Form a Ball

[0034] The φ2000 disc ball forming machine and the φ1500×4500 roller ball forming machine are used to form balls in two steps. That is to say, the above-mentioned grinding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com