High-strength high elasticity Cu-Ti alloy and its preparing process

A manufacturing method and high-elasticity technology, applied in the direction of temperature control, can solve the problems of reducing the yield of strips, prone to cracks, coarsening of ingot grains, etc., to improve the overall performance of alloys, optimize production processes, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

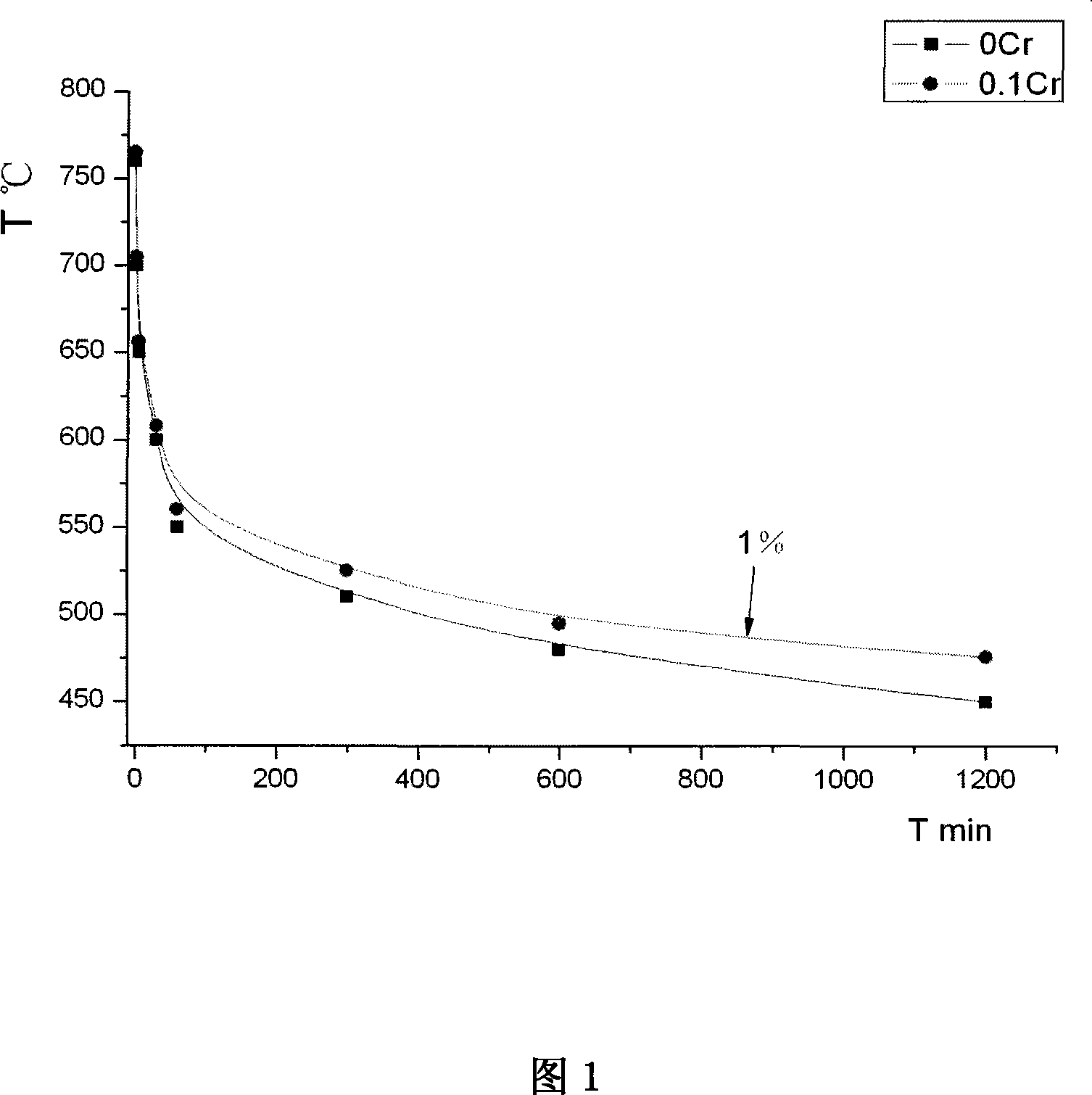

[0023] The technical scheme of the invention is to use inert gas protection for melting and casting to avoid the effect of alloy elements on oxygen and nitrogen in the air; gas protection is provided in the melting and pouring process to realize the continuous production of Cu-Ti alloy. In the rolling process, the final rolling temperature of hot rolling and the intermediate annealing temperature in the cold rolling process are slightly higher than the solid solution line of the alloy, which can effectively prevent the alloy from forming lamellar structure in this process. The particle size is controlled at 2-10 μm. Through a suitable aging process, the diameter of the Cu-Ti intermetallic compound phase on the section perpendicular to the rolling direction is controlled between 0.02 and 0.2 μm. By adding an appropriate amount of the third element group, the occurrence of overaging can be delayed, the occurrence of cellular reactions can be suppressed, and the electrical conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com