LCD backlight source structure of LED illumination

A LED lighting and backlight technology, applied in optics, nonlinear optics, instruments, etc., can solve problems affecting the brightness of LCD displays, increasing the thickness of LCD displays, reducing light utilization, etc., to facilitate heat dissipation and improve light intensity uniformity , the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

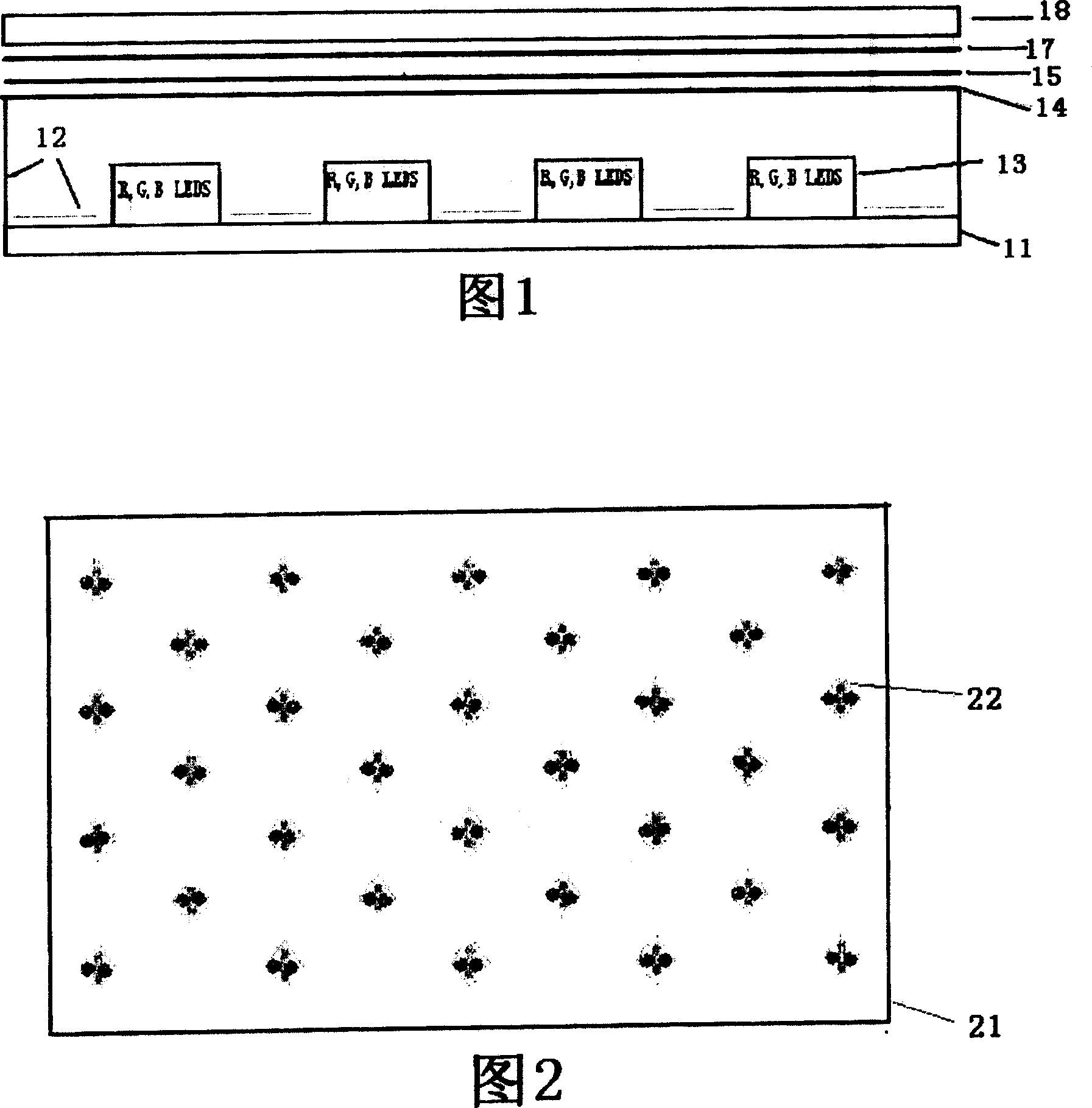

[0042] First, please refer to FIG. 6, which is the first embodiment of the present invention, an LCD backlight structure for LED lighting in the present invention, including:

[0043] A bracket 61, the bracket 61 is a box body with an opening at the top of the bottom surface connected to the heat dissipation plate, the inner side wall and the inner bottom surface of the box body are reflective surfaces 62;

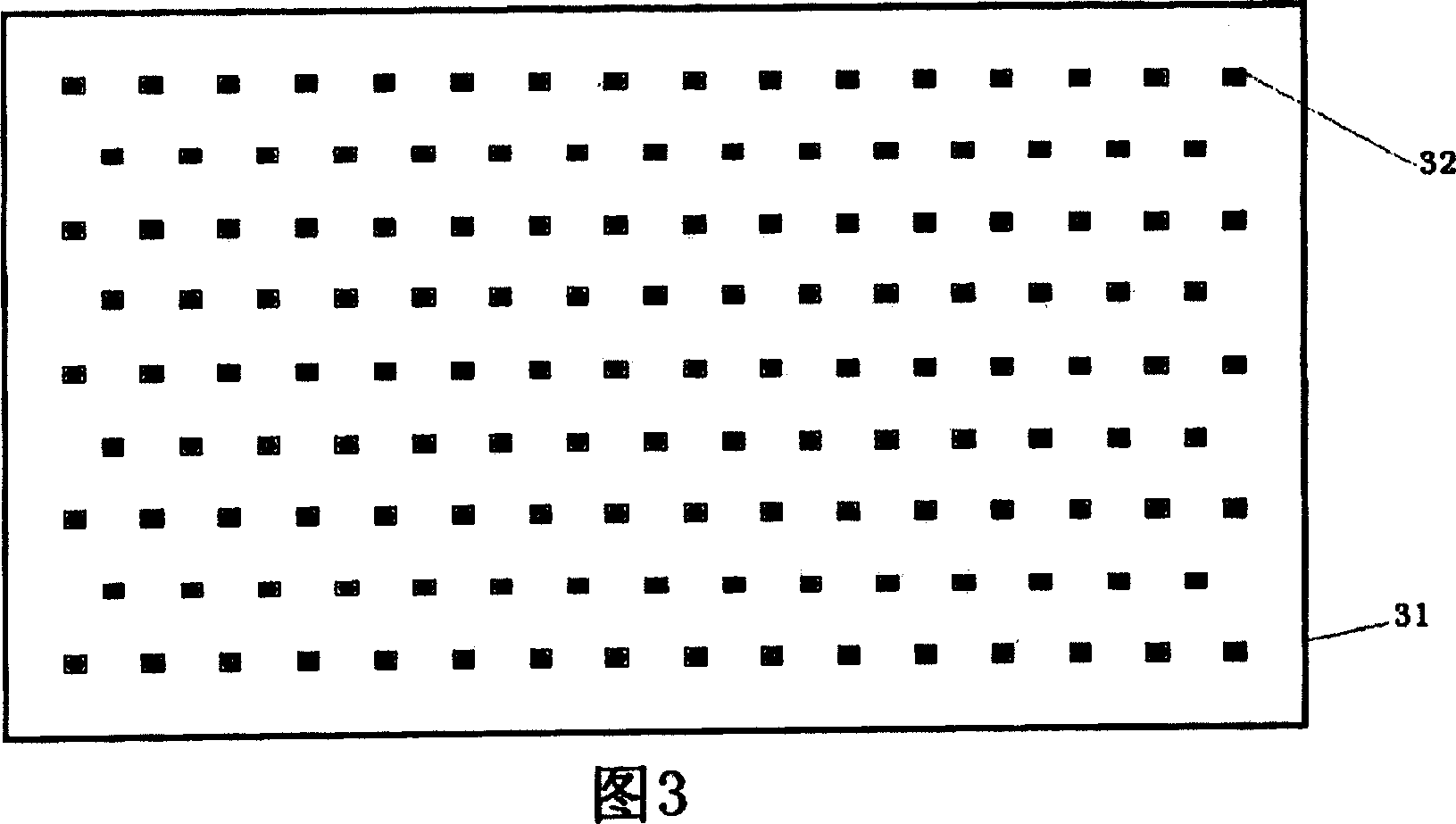

[0044] A two-dimensionally arranged monochromatic LED array 63, the monochromatic LED array 63 is made on the support 61 and arranged on the inner bottom surface of the support 6; the LED lamp used in the two-dimensionally arranged monochromatic LED array 63 is Monochromatic, the LED lamps used in the two-dimensionally arranged monochromatic LED array 63 are high-power ultraviolet LED lamps or blue LED lamps; the wavelength of the blue LED lamps used is 440nm-480nm;

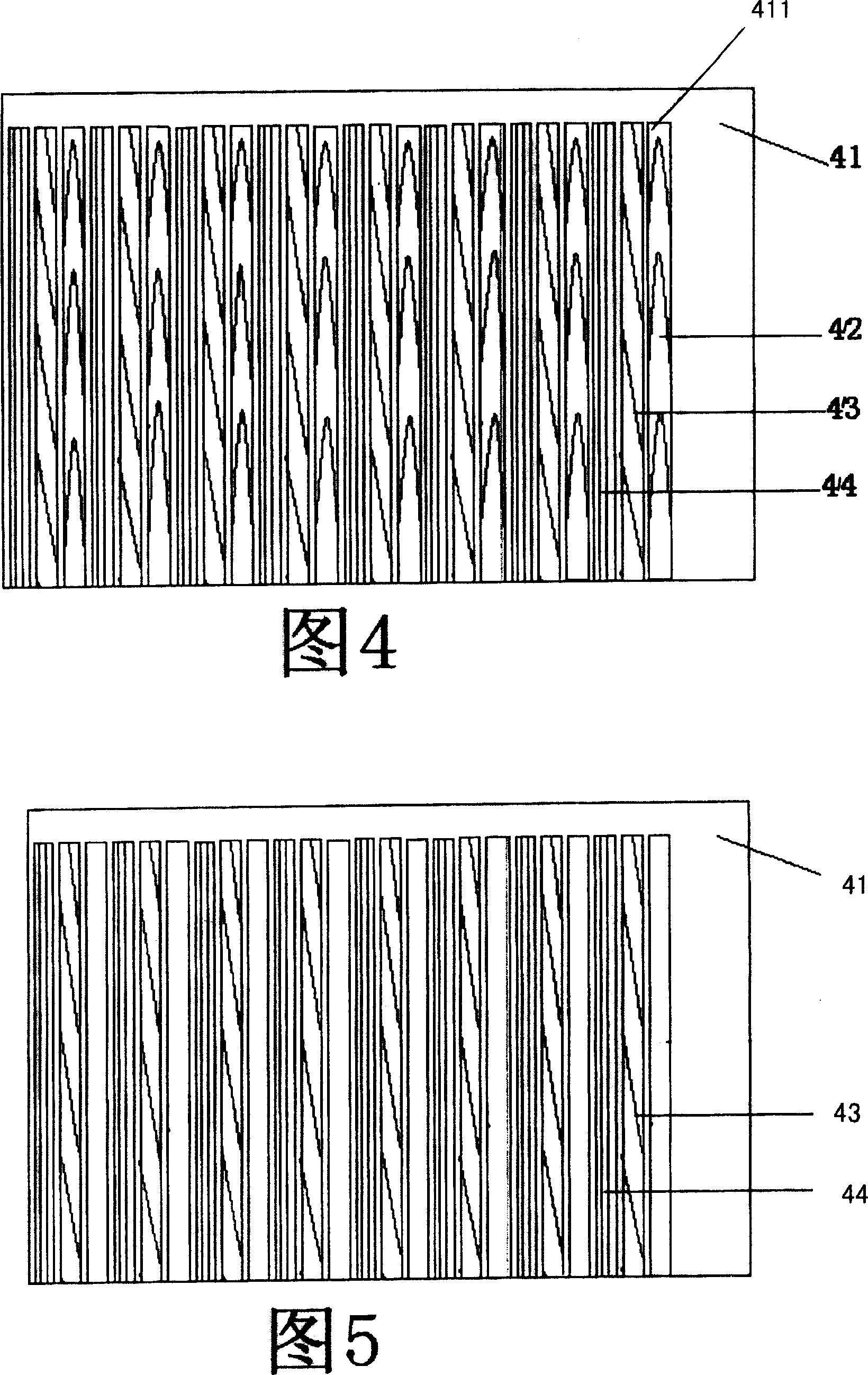

[0045] A diffusion plate 64, the diffusion plate 64 is fabricated above the two-dimensionally arranged mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com