A cable core of long stator coiling group cable and its making method

A long stator and winding technology, applied in cable/conductor manufacturing, textile cables, communication cables, etc., can solve the problems of not very smooth outer surface, poor softness, and low filling rate of the cable core, and achieve excellent mechanical properties and full filling The effect of high efficiency and easy bending and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

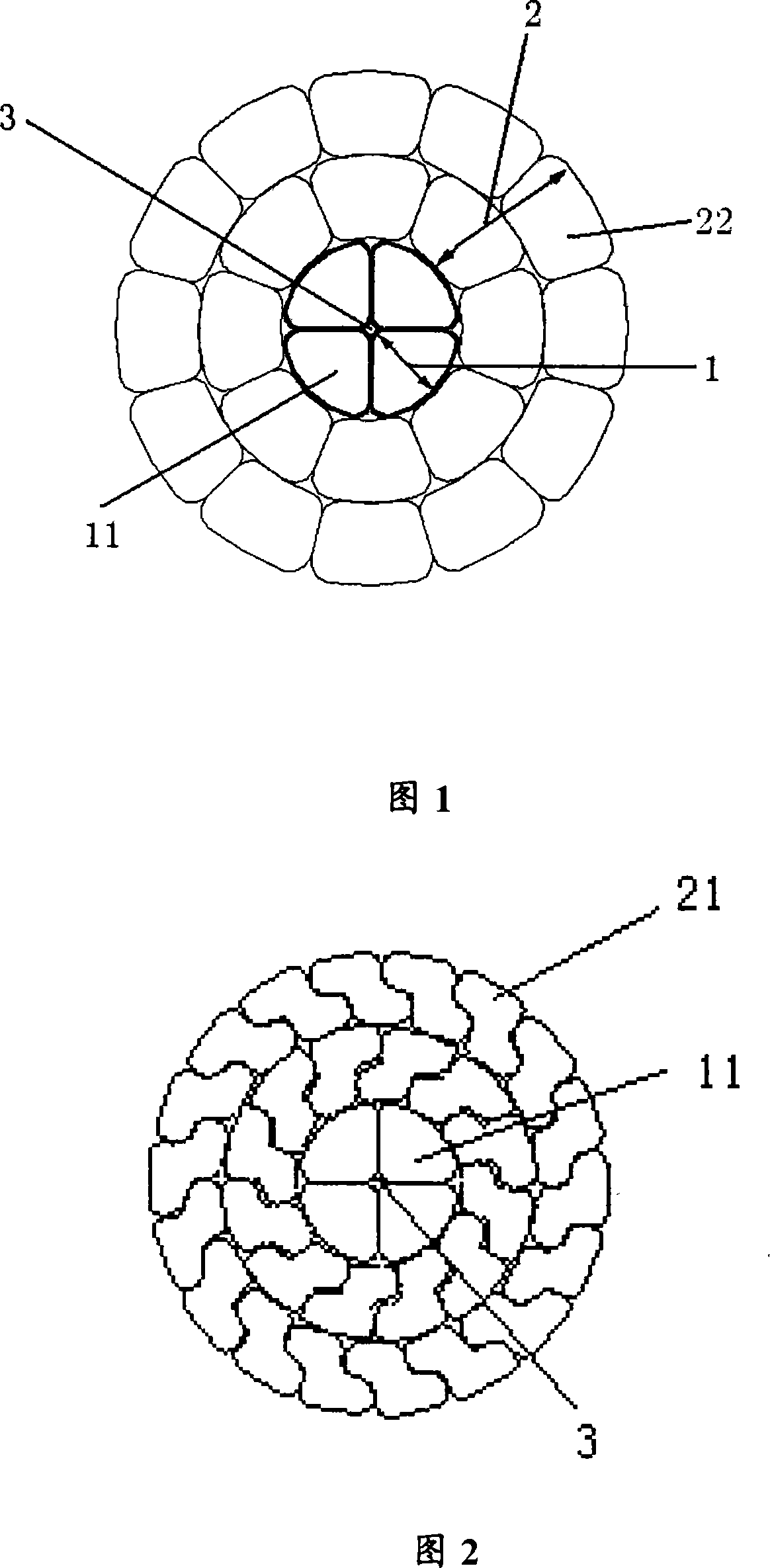

[0031] Please see Fig. 1, Fig. 1 is a schematic cross-sectional view of Embodiment 1 of a cable core of a long stator winding cable according to the present invention. As can be seen from Fig. 1, the cable core of the winding cable of the present invention is a multi-layer structure formed by twisting a plurality of single wires, including an inner core layer 1 and an outer core layer 2, and the inner core layer 1 is composed of four cross-sections of A circular core layer composed of fan-shaped inner core-type single wires. The corners of the fan-shaped single wires 11 have small rounded corners. After twisting, a central small hole 3 is formed in the center. This central small hole 3 along the cable axis, When the cable is running, it can circulate the air to reduce the temperature of the cable running and increase the carrying capacity of the cable. In the cable core of the winding cable of the present invention, the outer core layer 2 is a tubular structure made of a plura...

Embodiment 2

[0039] Please refer to FIG. 2 . FIG. 2 is a schematic cross-sectional view of Embodiment 2 of a cable core of a long stator winding cable according to the present invention. It can be seen from Fig. 2 that the cable core structure of the winding cable in this embodiment is similar to that of the winding cable in Embodiment 1, the difference is that the outer core type single wire in Embodiment 2 is a Z-shaped single wire 21, and the outer core type single wire is Z-shaped single wire 21. The first layer from the inside to the outside of the core layer 2 is a circle formed by twelve Z-shaped single wires 21 , and the second layer is a circle formed by eighteen Z-shaped single wires 21 .

[0040] The cable core of the winding cable in this embodiment uses copper-clad aluminum wire as the conductive material, and the conductivity of the copper-clad aluminum wire is 68.5% IACS (International Annealed Copper Standard Conductivity), which has better conductivity than previous conduct...

Embodiment 3

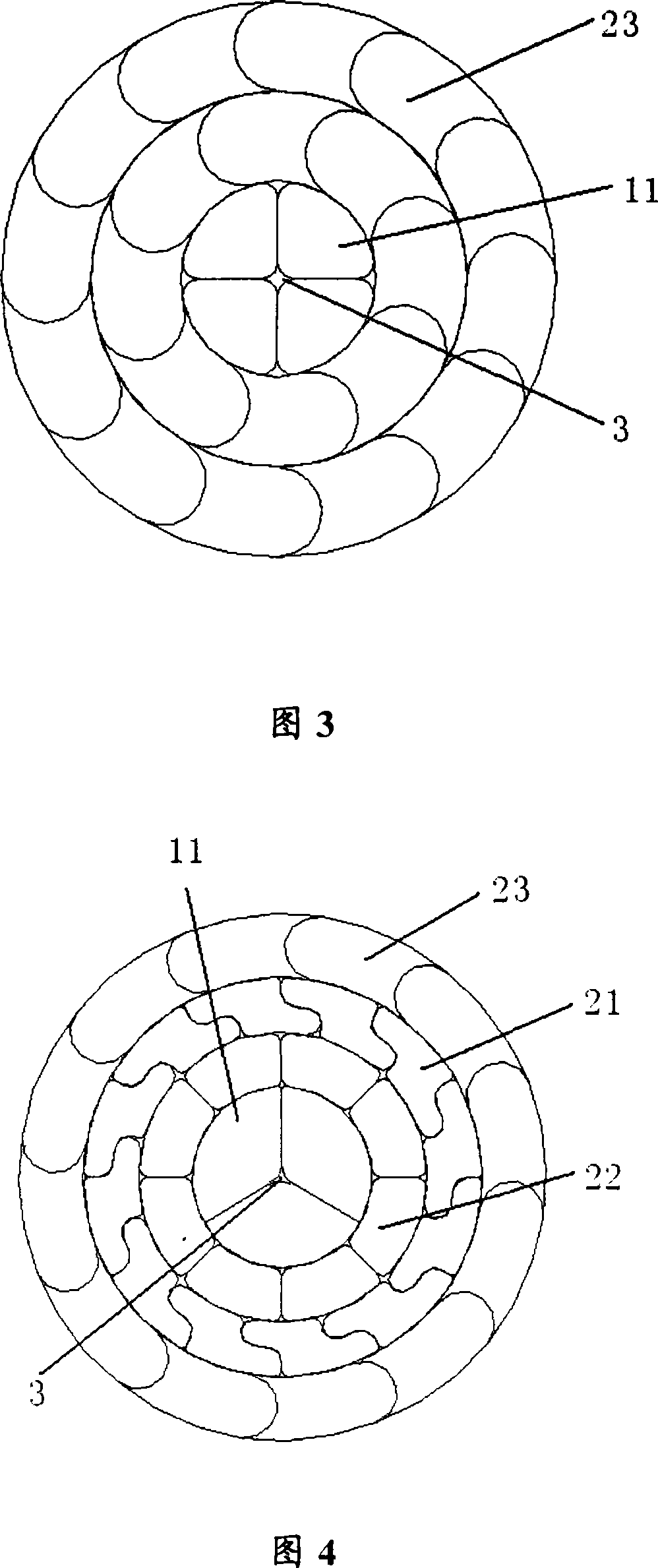

[0042] Please refer to FIG. 3 . FIG. 3 is a schematic cross-sectional view of Embodiment 3 of a cable core of a long stator winding cable according to the present invention. It can be seen from Fig. 3 that the cable core structure of the winding cable in this embodiment is similar to that of the winding cable in Embodiment 1, the difference is that the outer core type single wire in this embodiment is a C-shaped single wire 23, and the outer core type single wire 23 is The first layer from the inside to the outside of the core layer 2 is a circle formed by twelve C-shaped single wires 23 , and the second layer is a circle formed by eighteen C-shaped single wires 21 .

[0043] The cable core of the winding cable in this embodiment uses electrical aluminum as the conductive material, and the electrical conductivity of the electrical aluminum is 63% IACS (International Annealed Copper Standard Conductivity), which has better conductivity than the previous conductive materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com