Molten-salt growth method for zinc oxide single crystal

A zinc oxide single crystal and growth method technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of lower growth temperature, high crystal price, complicated equipment, etc., and achieve the effect of improving quality and clear screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

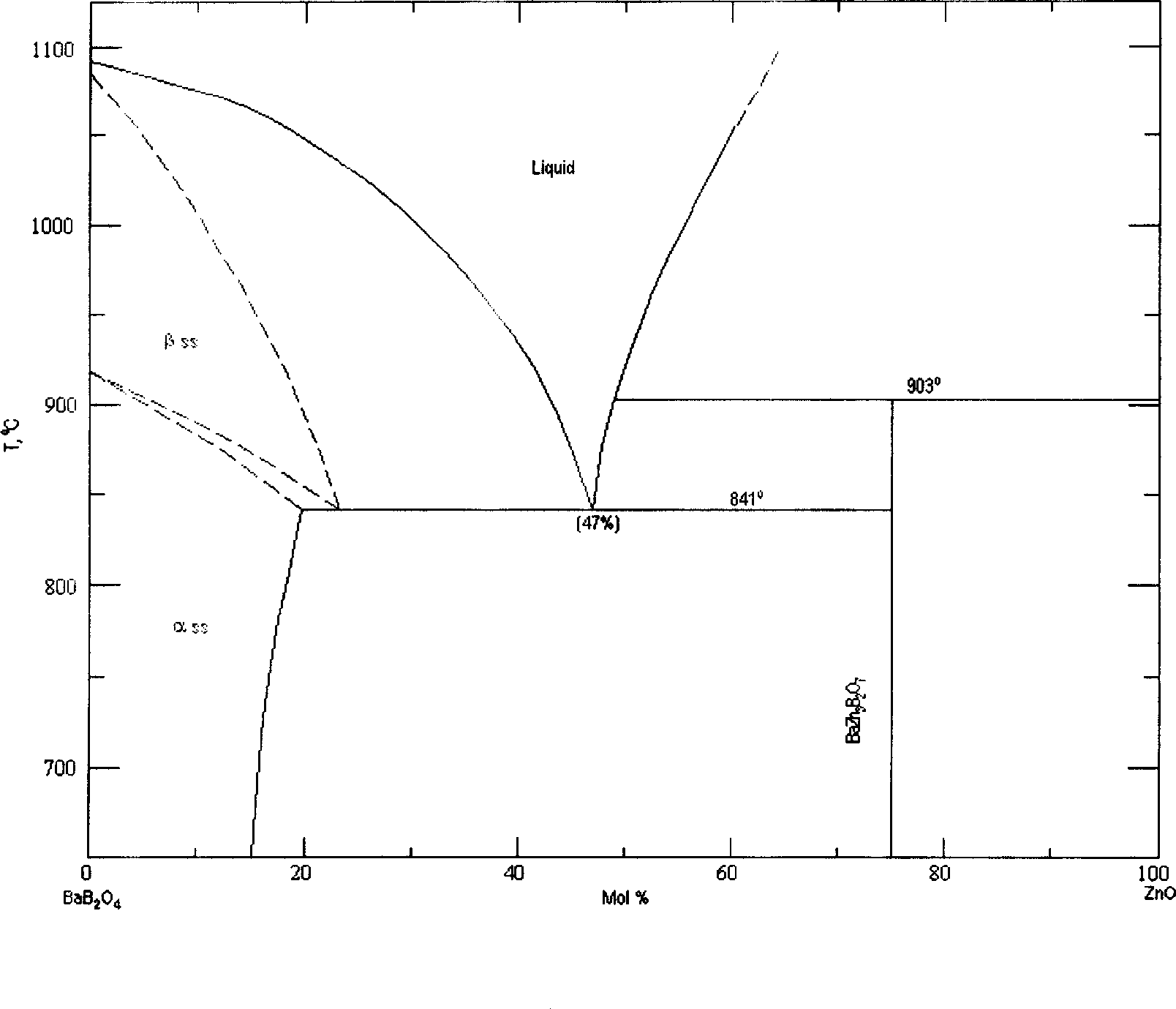

[0020] The ZnO single crystal was grown by the molten salt method, and the raw materials used were analytically pure BaO and H 3 BO 3 , and spectrally pure ZnO. The flux is selected from BaO-B 2 o 3 -ZnO system. Then carry out batching according to the following ratio: BaO: B 2 o 3 :ZnO=35mol%: 35mol%: 65mol%.

[0021] After the raw materials are weighed, they are ground and mixed evenly with an agate mortar, and then put into a platinum crucible of Ф55mm×60mm, placed in a growth furnace, heated up until the raw materials are melted, crystallized spontaneously, and the seed crystals grow first. Then use the trial seed crystal method to measure the saturation temperature of the melt to be about 1100°C, keep the temperature at about 50°C above the saturation temperature for 24 hours, then lower the seed crystal to the melt, and drop to the saturation temperature after half an hour. The temperature was lowered at a rate of ℃ / d, and after about 10 days of growth, the crysta...

Embodiment 2

[0024] The ZnO single crystal was grown by the molten salt method, and the raw materials used were analytically pure BaO and H 3 BO 3 , and spectrally pure ZnO. The flux is selected from BaO-B 2 o 3-ZnO system. Then carry out batching according to the following ratio: BaO: B 2 o 3 :ZnO=40mol%: 40mol%: 60mol%.

[0025] After the raw materials are weighed, they are ground and mixed evenly with an agate mortar, and then put into a Ф55mm×60mm platinum crucible, placed in a growth furnace, heated up until the raw materials are melted, crystallize spontaneously, and grow seed crystals first. Then use the seed crystal method to measure the saturation temperature of the melt to be about 1050°C, keep the temperature at about 50°C above the saturation temperature for 24 hours, then lower the seed crystal to the melt, and drop to the saturation temperature after half an hour, start with 2 to 15 The temperature is lowered at the rate of ℃ / d, and the method of periodically accelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com