Flyash ceramisite sintered open-hearth furnace

A fly ash ceramsite and open hearth furnace technology, applied in the field of sintering furnaces, can solve the problems of difficult quality control, environmental pollution efficiency, etc., and achieve the effects of good sealing performance, uniform combustion, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

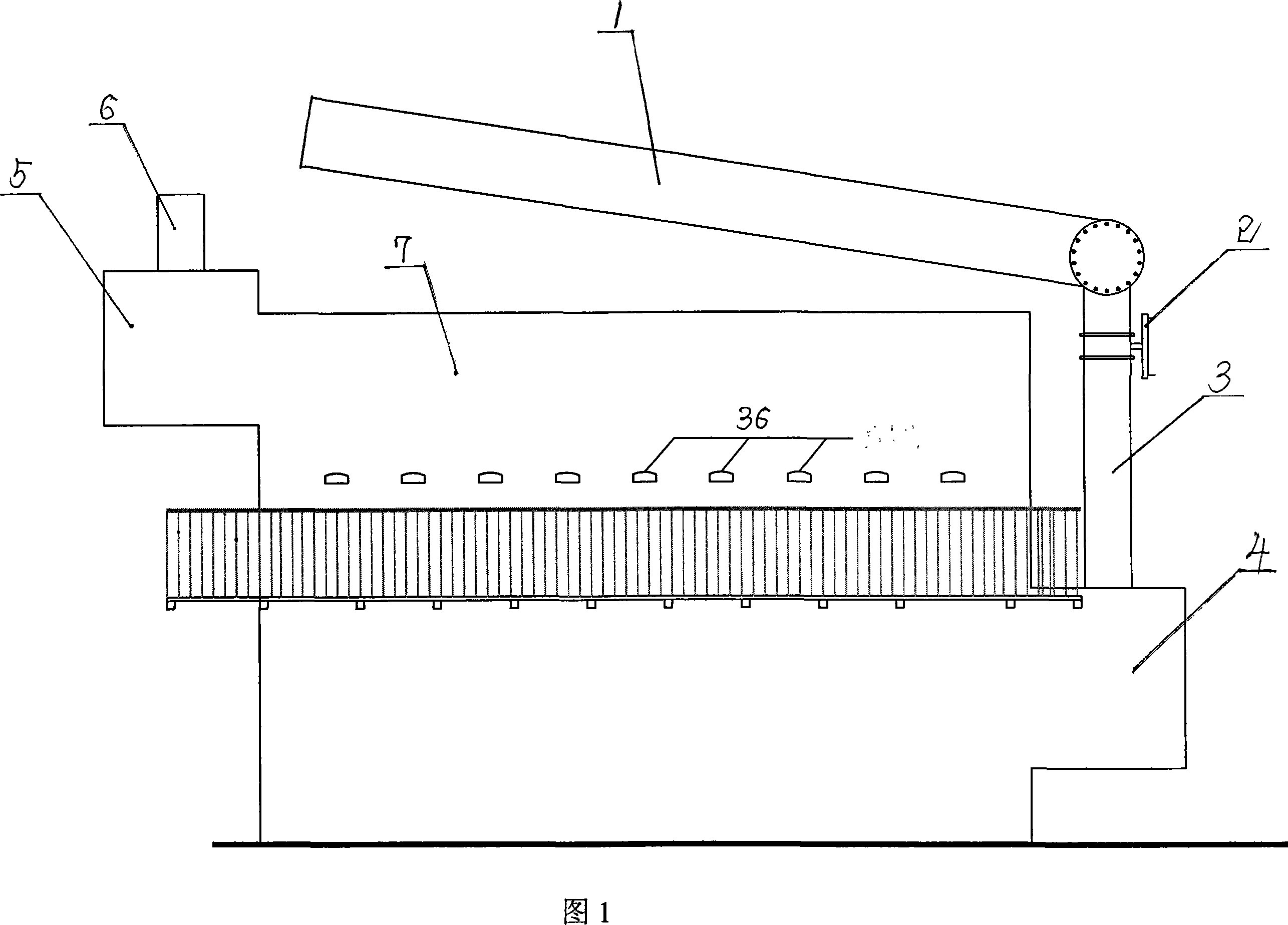

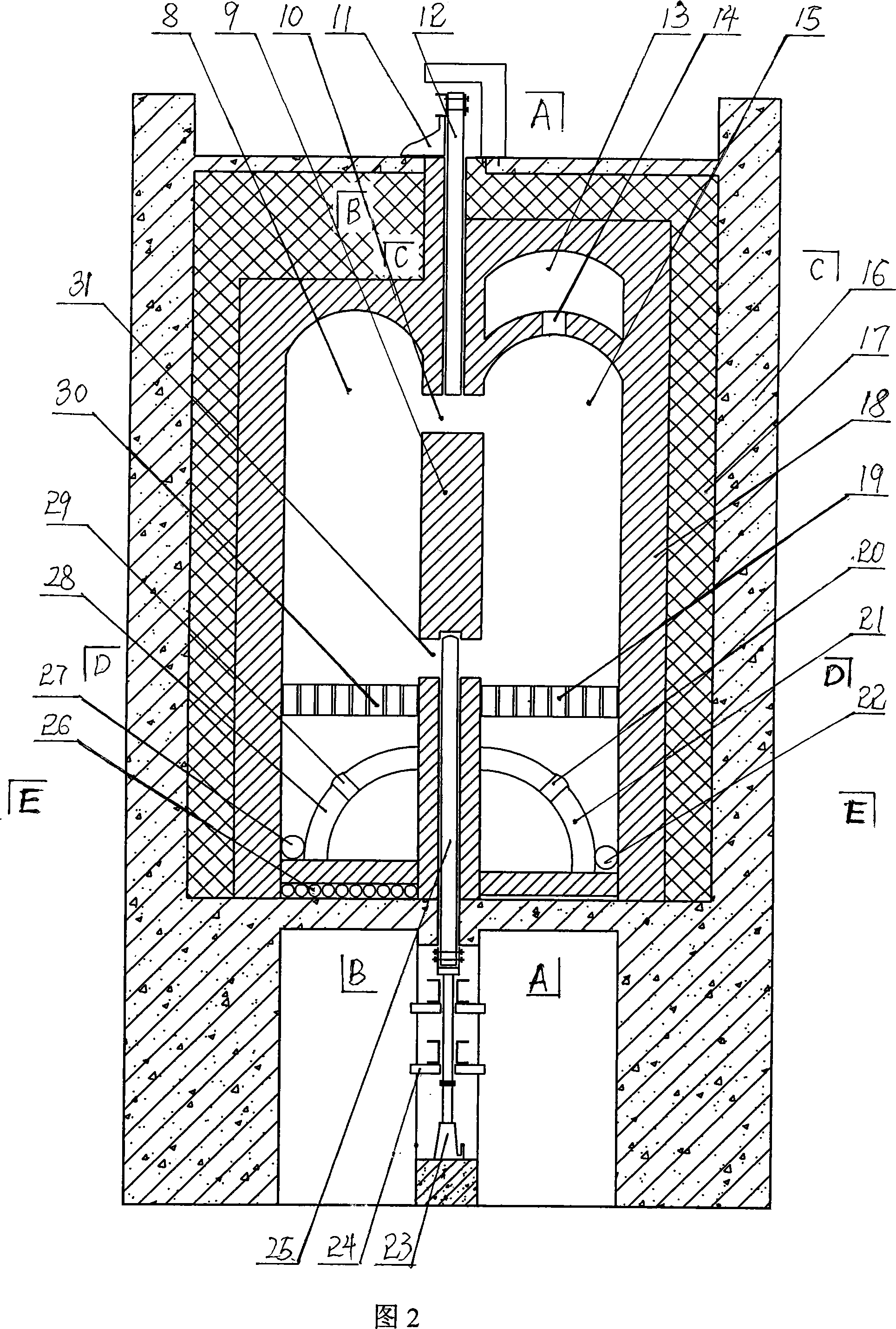

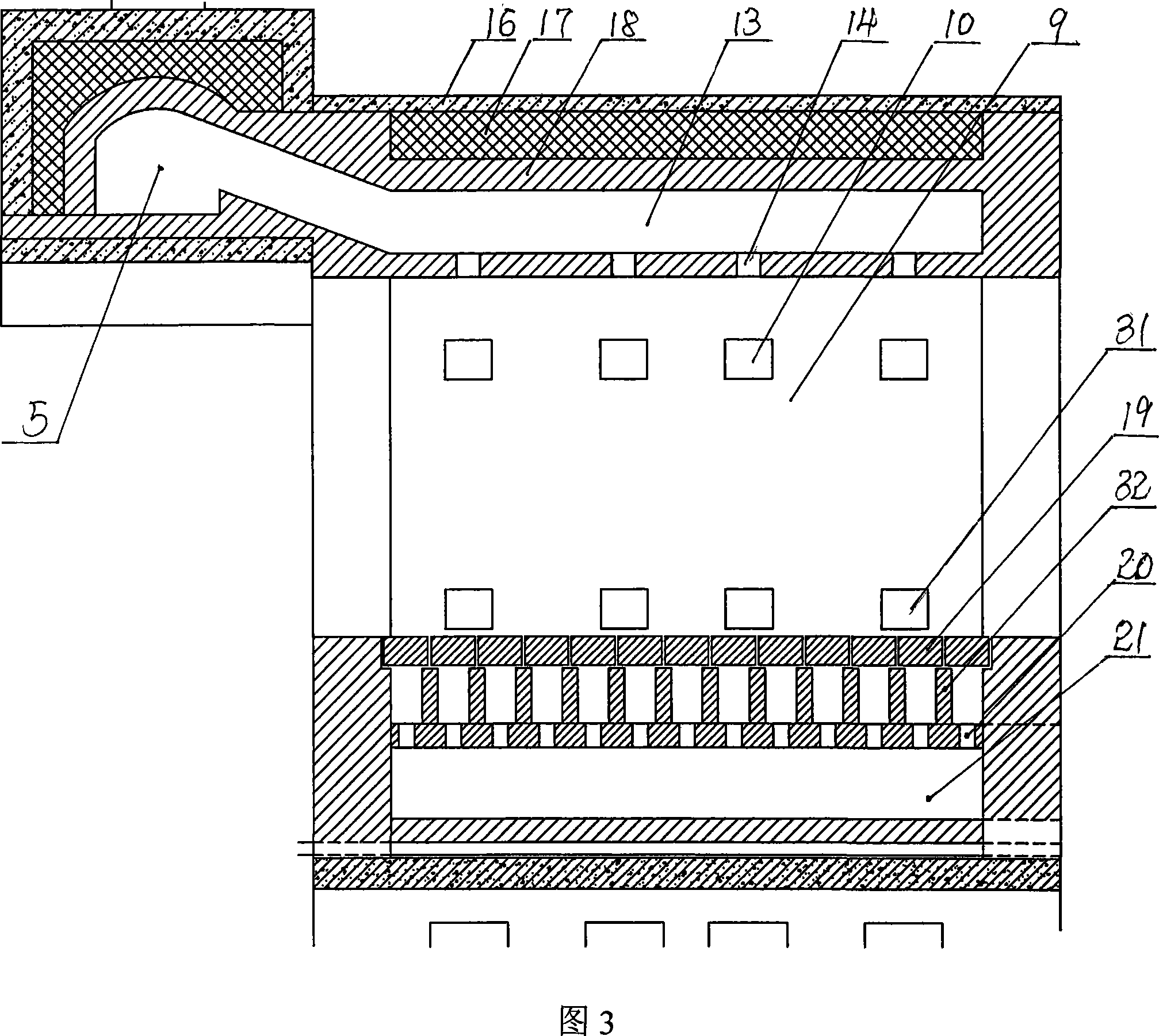

[0017] As shown in Figures 2 and 6, a fly ash ceramsite sintered open hearth furnace includes a furnace body 7, a left combustion chamber 8 and a right combustion chamber 15 are provided in the furnace body, and a combustion chamber between the left combustion chamber 8 and the right combustion chamber 15 The upper crater 10 and the lower crater 31 are arranged on the partition wall 9, the upper ram 12 is worn above the upper crater 10 in the partition wall 9, and the lower ram 25 is worn below the lower crater 31 in the partition wall 9, and the left burning There is a left fire grate 30 in the middle of the chamber 8, a right fire grate 19 in the middle of the right combustion chamber 15, a flue passage 13 is provided above the right combustion chamber 15, and a flue passage 13 is provided between the flue passage 13 and the right combustion chamber 15. 14 through the smoke port. Body of furnace 7 is made up of resistance wall 16, thermal insulation layer 17, refractory wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com