Preparing multistage adsorbent for difficult degradative organic wastewater in high concentration, and method of use

An organic wastewater, high-concentration technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as difficult to remove persistent organic pollutants in wastewater, and achieve convenient regeneration, large adsorption capacity, The effect of good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

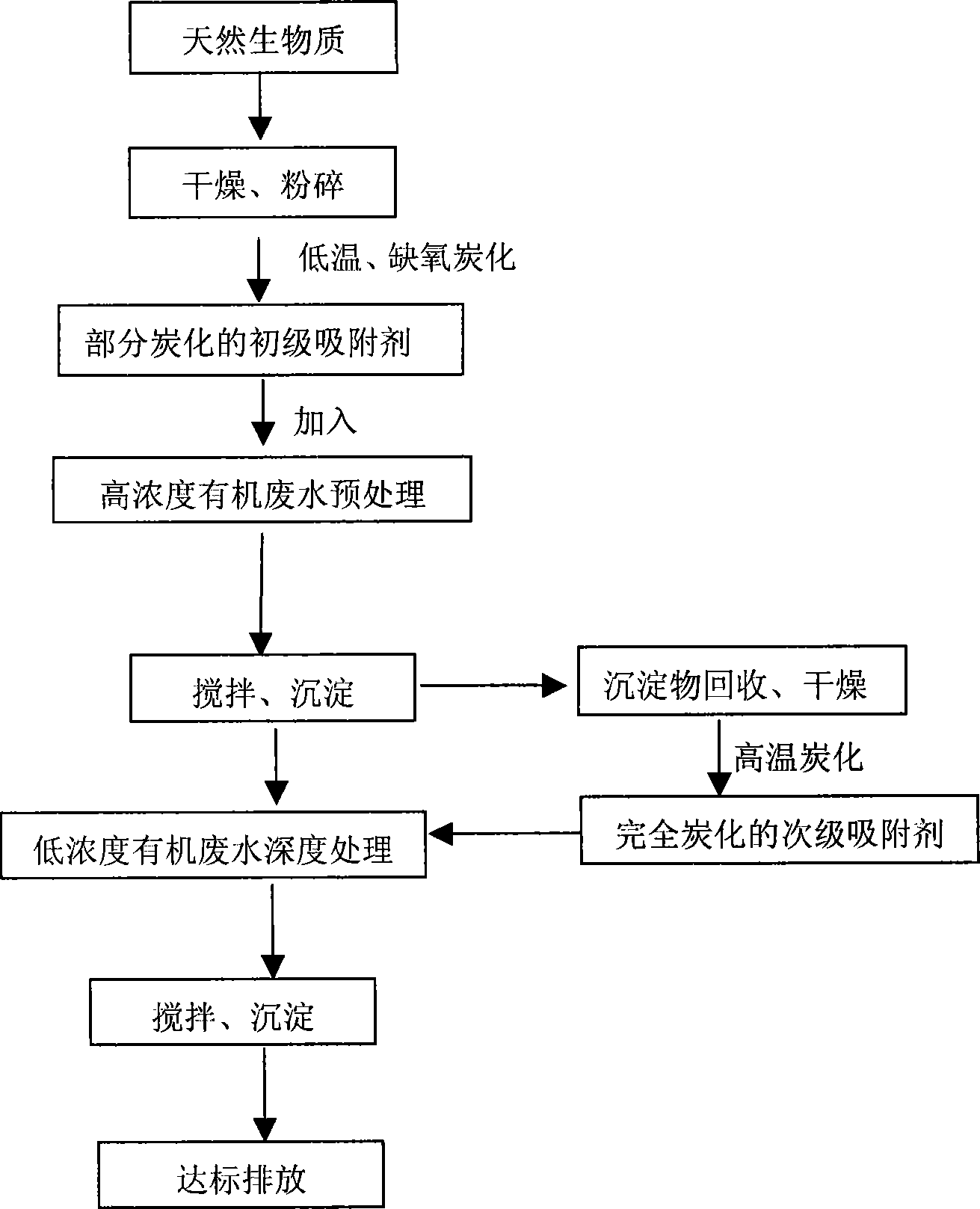

[0020] 1) Carbonize pine needles at 100°C for 2 hours under anaerobic conditions to make a partially carbonized primary adsorbent;

[0021] 2) Put part of the carbonized primary adsorbent into the high-concentration organic wastewater, the mass volume ratio of the adsorbent to the high-concentration organic wastewater is 1:500, and after stirring, remove the high-concentration organic pollutants in the wastewater; after precipitation, recover and adsorb organic pollution The partially carbonized primary adsorbent was dried and further carbonized at 400°C for 2 hours to obtain a completely carbonized secondary adsorbent.

Embodiment 2

[0023] 1) Carbonize orange peel for 6 hours at 200°C under hypoxic conditions to make a partially carbonized primary adsorbent;

[0024] 2) Put part of the carbonized primary adsorbent into the high-concentration organic wastewater, the mass-volume ratio of the adsorbent to the high-concentration organic wastewater is 1:10000, and after stirring, remove the high-concentration organic pollutants in the wastewater; after precipitation, recover and adsorb organic pollution The partially carbonized primary adsorbent was dried and further carbonized at 700°C for 6 hours to obtain a completely carbonized secondary adsorbent.

Embodiment 3

[0026] 1) Carbonize the fruit shell for 4 hours at 150°C under anoxic conditions to make a partially carbonized primary adsorbent;

[0027] 2) Put part of the carbonized primary adsorbent into the high-concentration organic wastewater, the mass volume ratio of the adsorbent to the high-concentration organic wastewater is 1:800, and after stirring, remove the high-concentration organic pollutants in the wastewater; after precipitation, recover and adsorb organic pollution The partially carbonized primary adsorbent was dried and further carbonized at 600°C for 4 hours to obtain a completely carbonized secondary adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com