Test equipment of steady state operation life in use for controlling junction temperature of transistor

A technology for controlling transistors and test equipment, applied in semiconductor/solid-state device testing/measurement, single semiconductor device testing, measuring devices, etc., can solve the problem of failure to eliminate defective products, reduce test reliability, and reduce test reliability and other issues to achieve the effect of easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

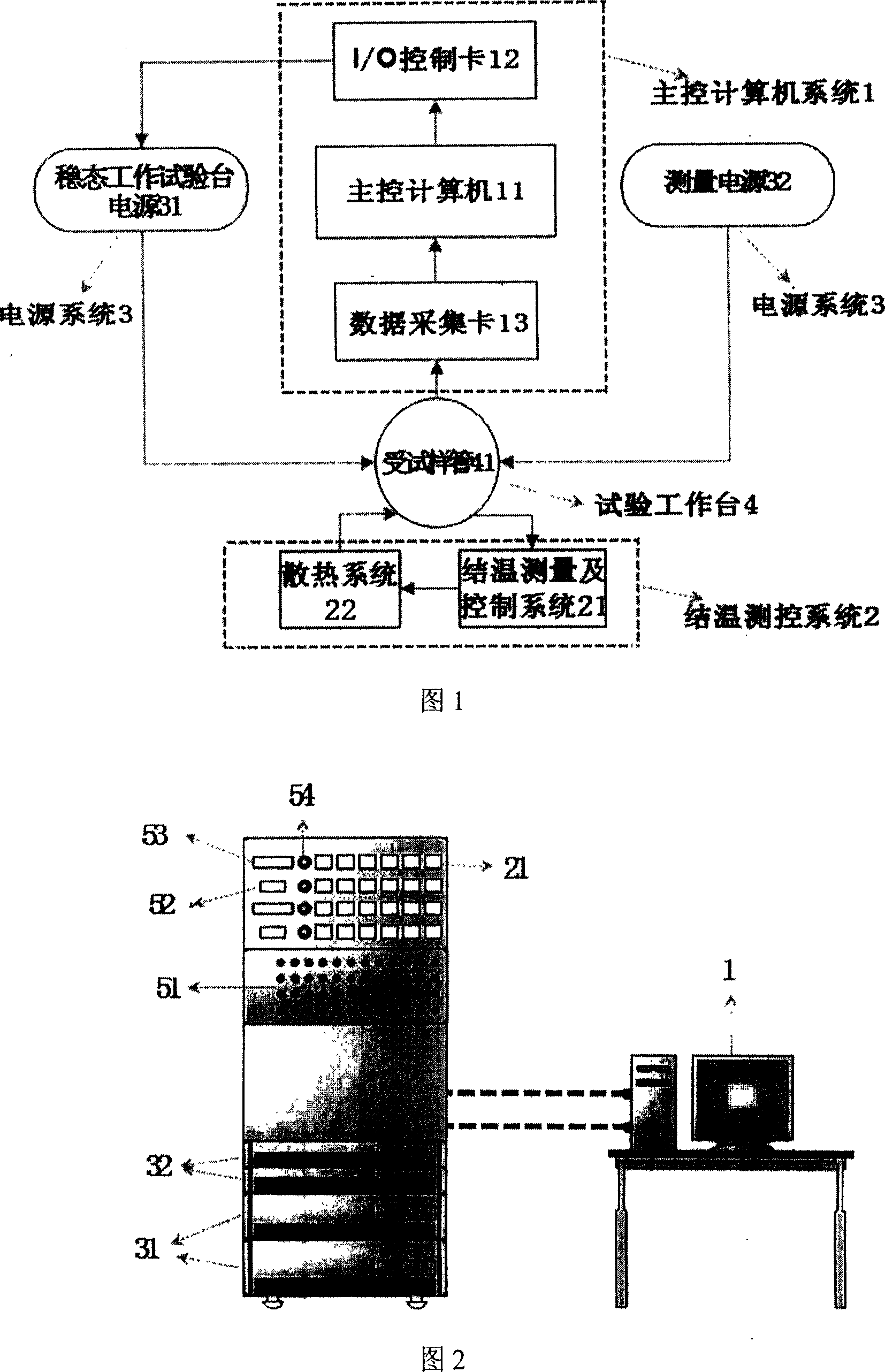

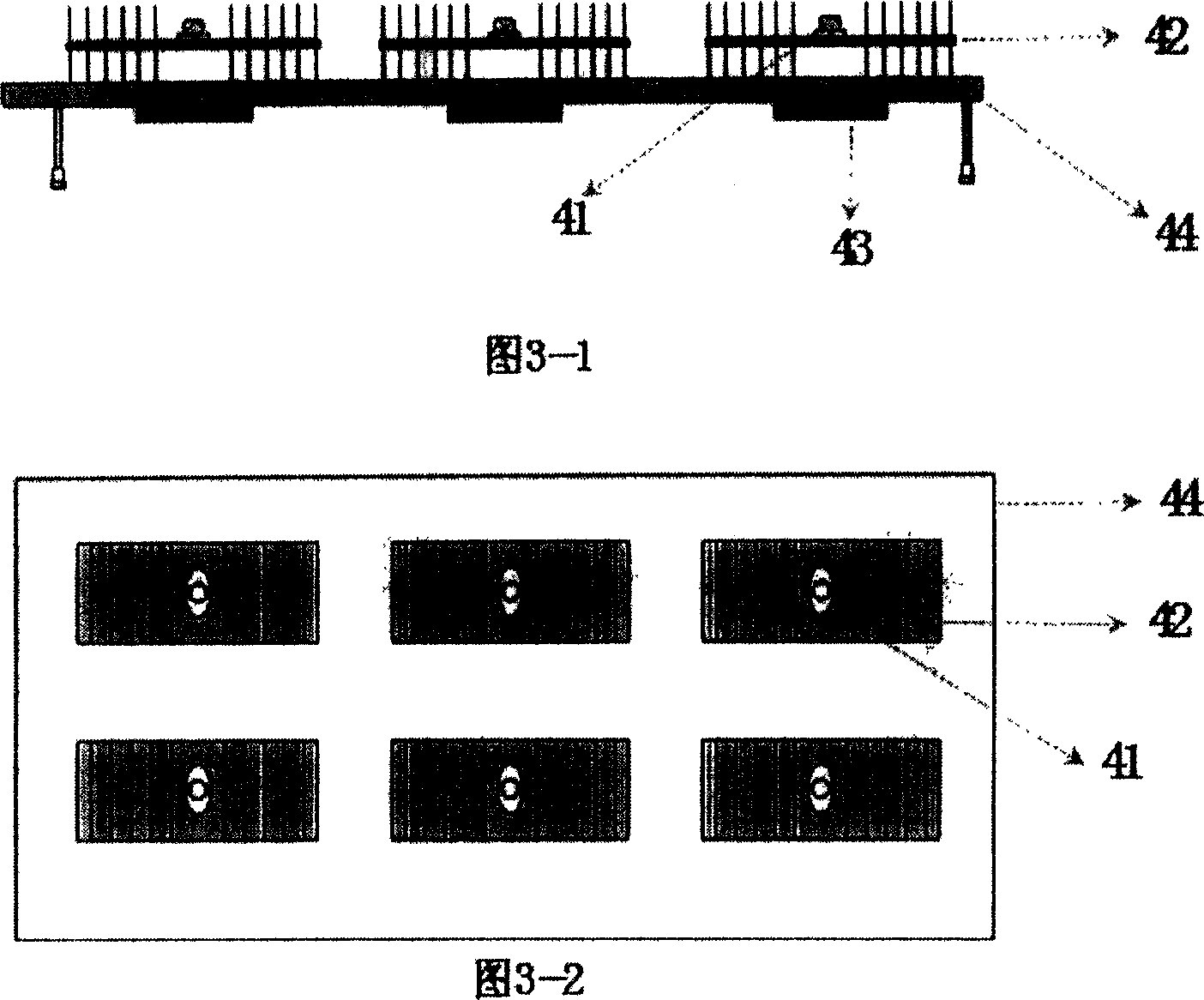

[0045] Please refer to shown in Fig. 1, a kind of steady-state working life test equipment of controlling transistor junction temperature of the present invention, it is by control system (comprising main control computer system 1 and junction temperature measurement and control system 2), power supply system 3 and test bench 4 composition. The control system is composed of a main control computer system 1 and a junction temperature measurement and control system 2 .

[0046] The main control computer system 1 includes a main control computer 11 , a data acquisition card (ie 1713 card) 13 and an I / O control card (ie 1734 card) 12 . The data acquisition card 13 is connected to the base and the emitter of each sample tube 41, and the data acquisition card 13 is used for real-time collection of the forward voltage drop V between the base and the emitter of the sample tube 41. BE And input main control computer 11 to process and record. I / O control card 12 links to each other wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com