Sodium lamp in low pressure

A low-pressure sodium lamp and metal sodium technology, applied in the field of electric light sources, can solve the problems of poor use durability, poor light collection effect, large heat dissipation surface, etc., and achieve the effects of small heat dissipation surface, high light transmittance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

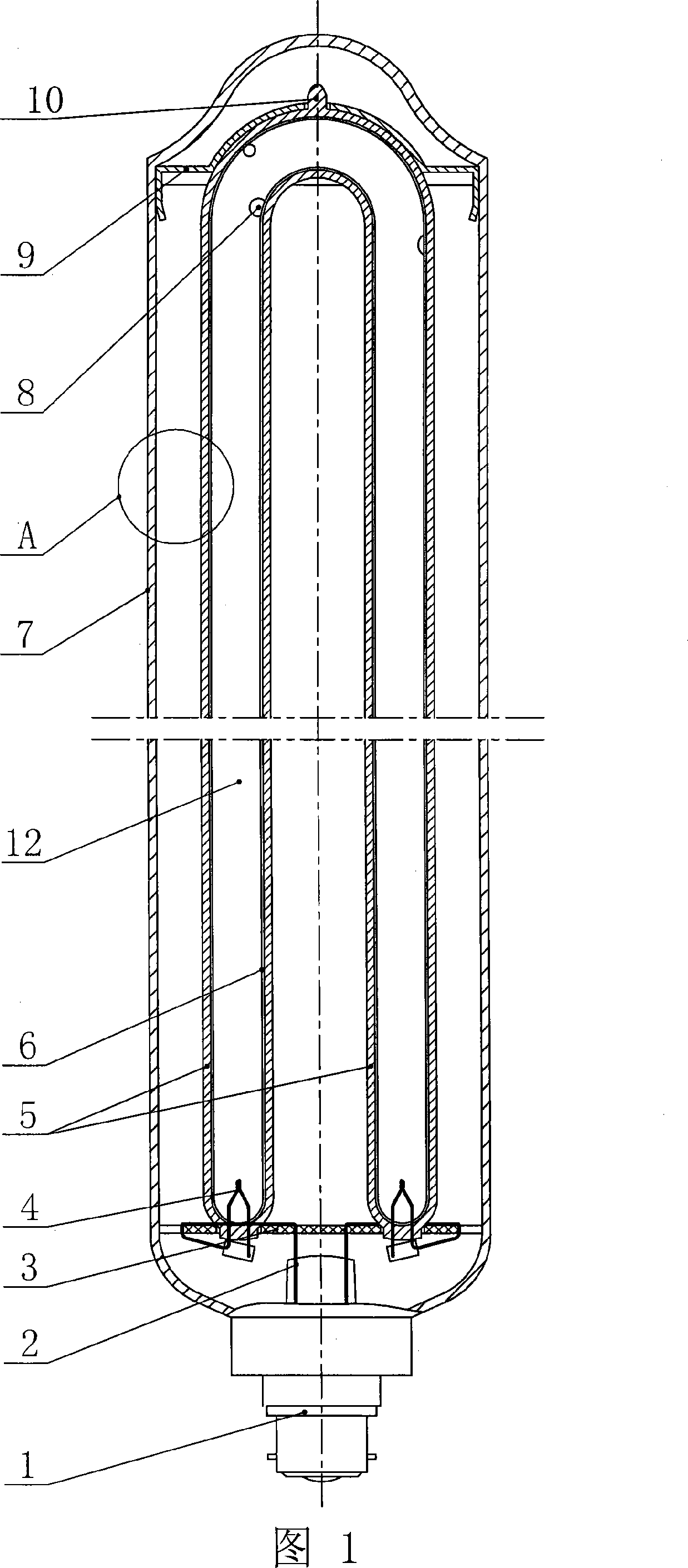

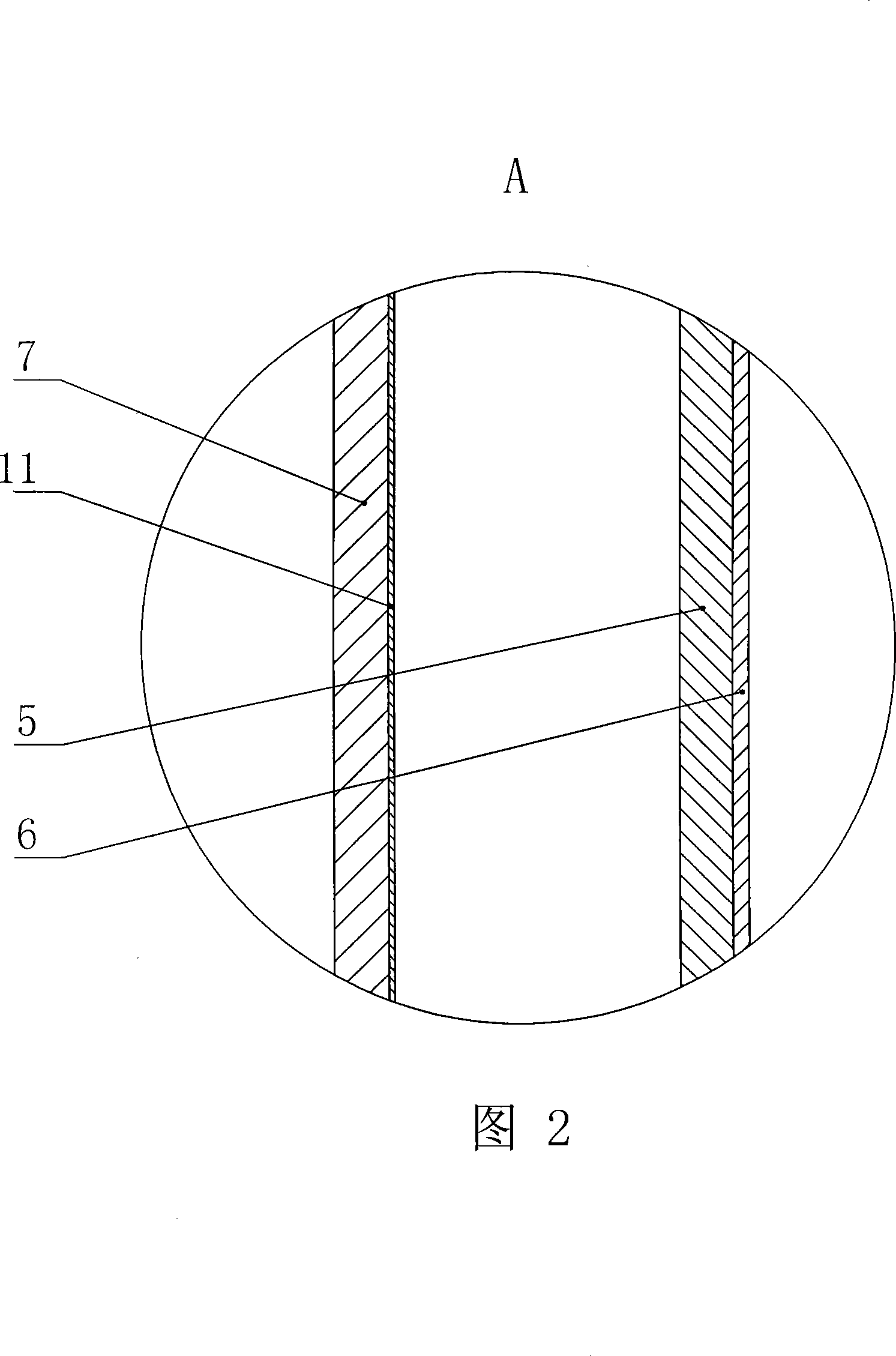

[0012] As shown in the figure: the low-pressure sodium lamp is mainly composed of a discharge tube 12 and a transparent outer glass bulb 7. The discharge tube 12 is encapsulated with an inert gas and metal sodium 8. The discharge tube 12 is U-shaped and fixed on a high-vacuum cylinder through a support frame. Inside the transparent outer glass envelope 7; the inner wall of the outer glass envelope 7 is provided with an infrared reflective light-transmitting film 11, the infrared reflective light-transmitting film 11 is made of indium oxide as the main material, and is equipped with tin oxide and a medium liquid at a high temperature of 500°C-600°C In the environment, it is physically formed on the inner wall of the outer glass bulb 7, and the two poles of the discharge tube 12 are provided with electrodes 4. The electrodes 4 can be connected to the external power supply through the stem 2 and the lamp cap 1, which are relatively fixed to the outer glass bulb 7. The electrodes 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com