GESBTE thin film manufacturing method, phase-change direct-access storage and manufacturing method therefor

A manufacturing method and a random phase transition technology, which are applied in static memory, digital memory information, information storage, etc., can solve problems such as difficulty in forming GeSbTe thin films, and achieve the effect of good crystallinity and surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

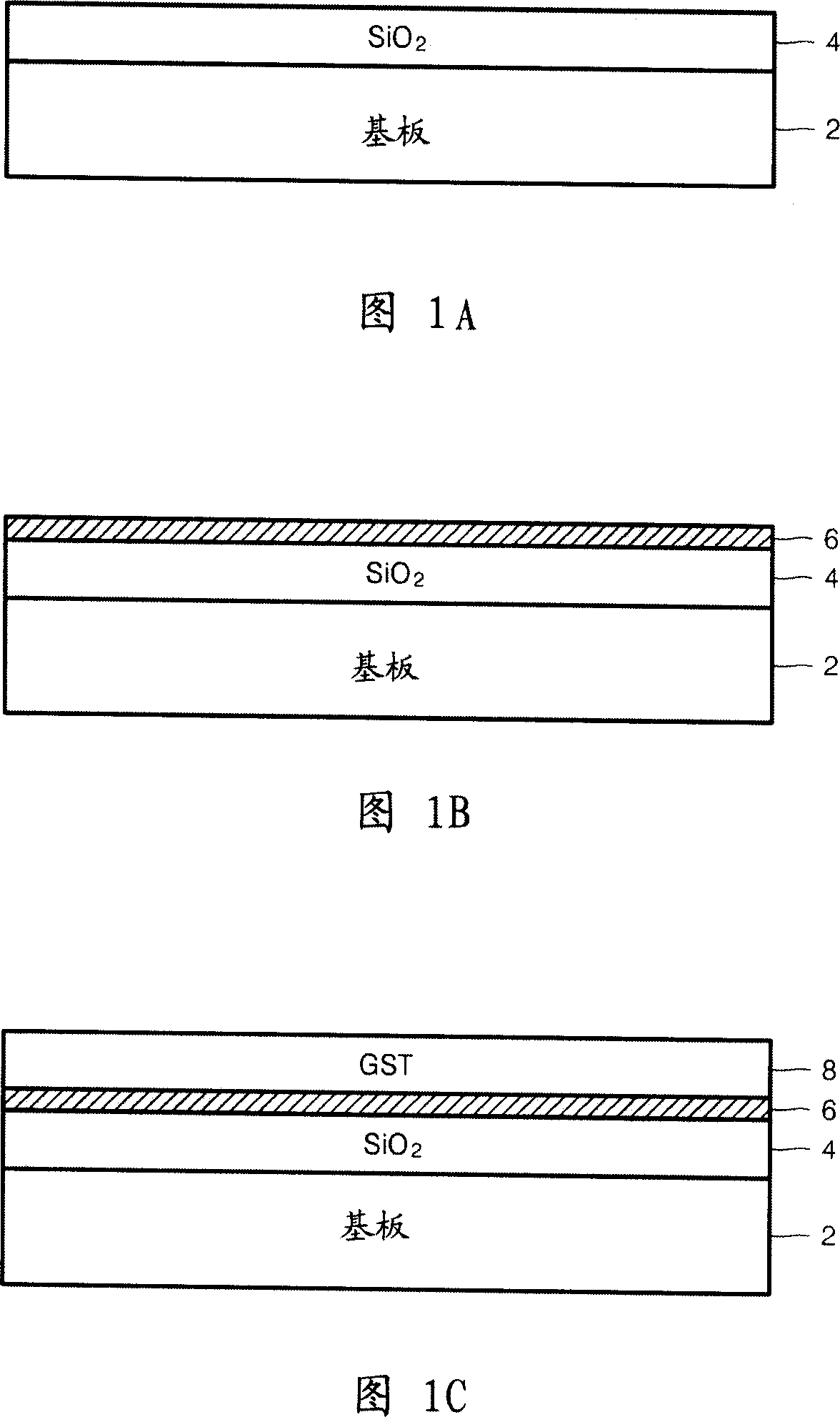

[0024] The invention will be described more fully hereinafter with reference to the accompanying drawings, in which preferred embodiments of the invention are shown. In the drawings, the thicknesses of layers and regions are exaggerated for clarity.

[0025] 1A, 1B and 1C are cross-sectional views illustrating a method of manufacturing a GeSbTe thin film according to an embodiment of the present invention. 1A to 1C, one or two selected from the group consisting of a Ge precursor, a Sb precursor and a Te precursor are supplied to the surface of an amorphous material layer 4 formed on a substrate 2, thereby forming a layer composed of Ge, Sb, Te, Sb 2 Te 3 Or the seed layer 6 made of Ge doped with Sb. Next, a Ge precursor, a Te precursor, and an Sb precursor are supplied to the surface of the seed layer 6 , thereby forming the GeSbTe thin film 8 . Here, the seed layer 6 has good adhesion to the amorphous material layer 4 and can provide nucleation sites for forming the GeSbT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com