Ultrasonic solution separating method and ultrasonic separating apparatus used in this method

A separation method and separation device technology, which is applied in the field of separating target substances contained in solutions and separating solutions with high concentration of target substances, can solve the problems of ethanol production and low temperature, and achieve the effect of efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

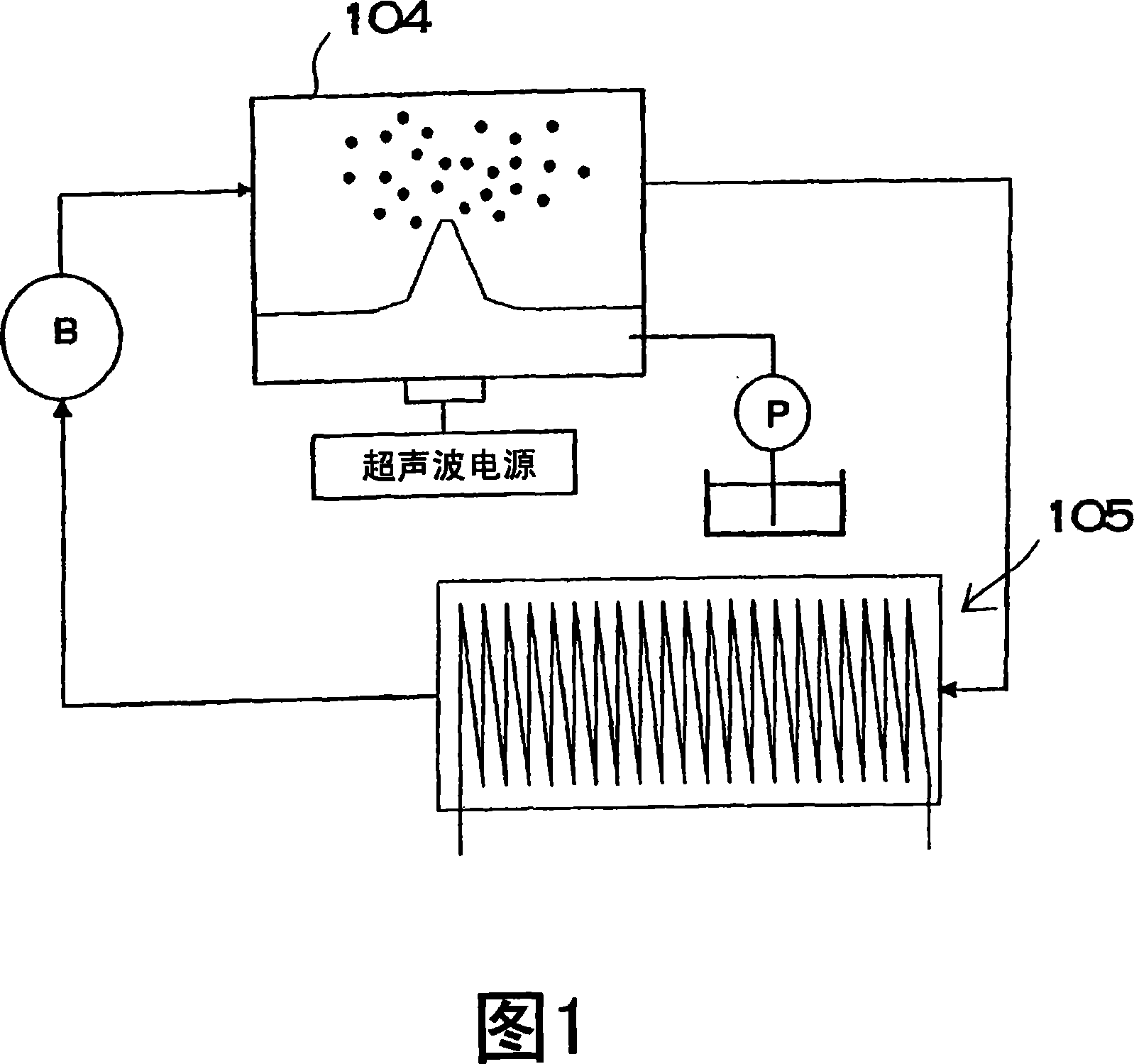

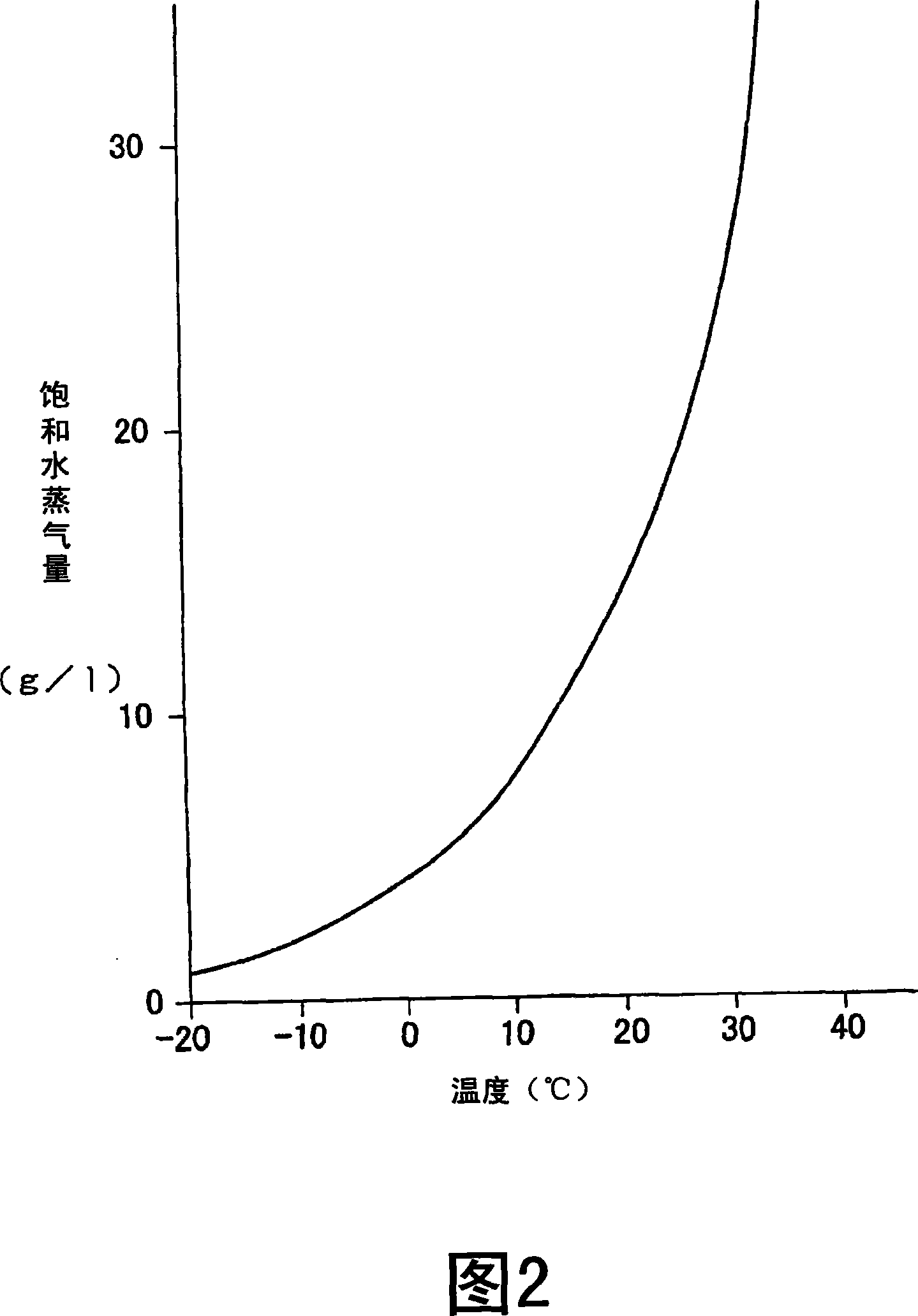

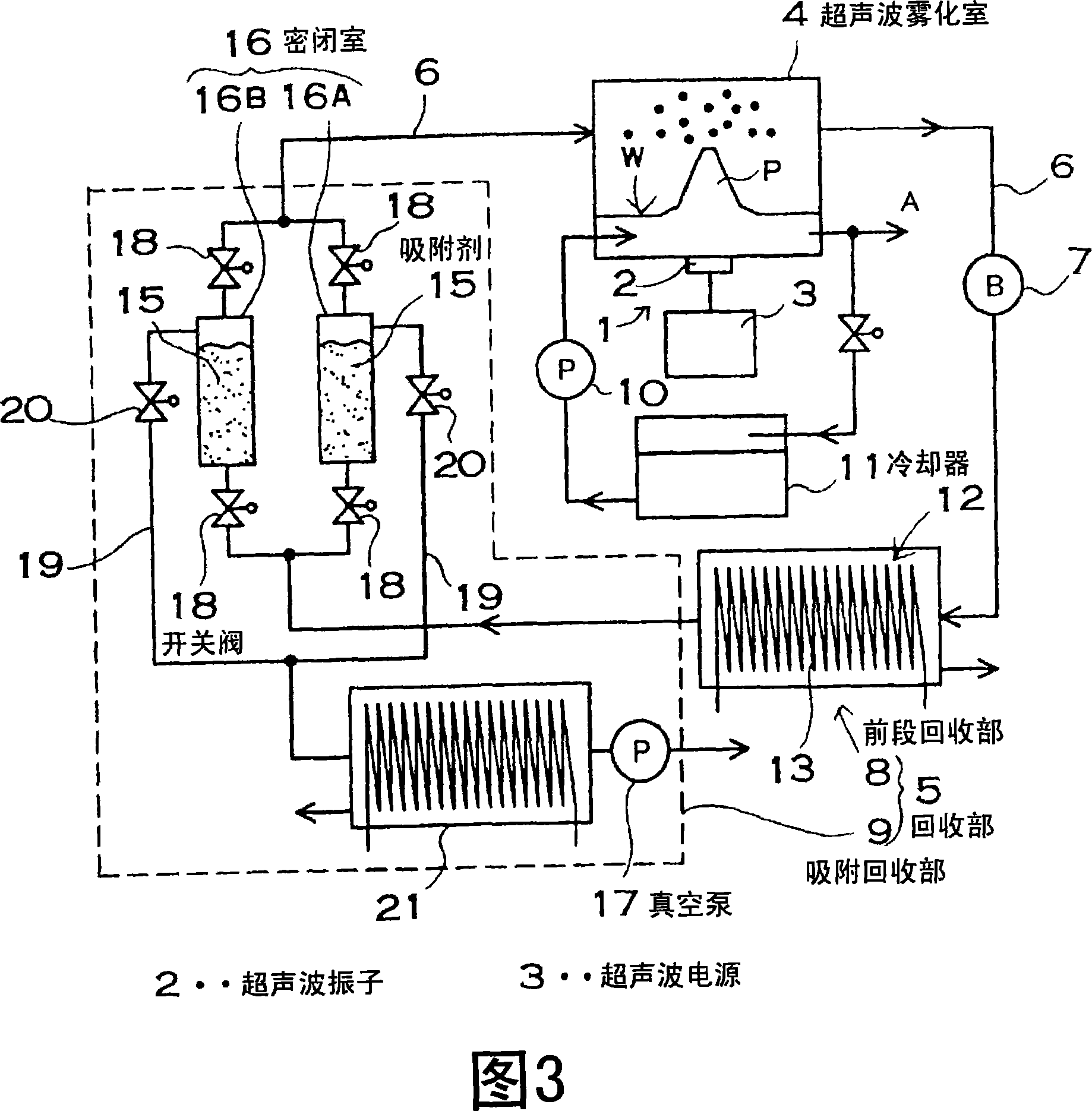

[0059] Embodiments of the present invention will be described below with reference to the drawings. The embodiments shown below are examples of the ultrasonic separation method and ultrasonic separation device for solutions embodying the technical concept of the present invention, and the ultrasonic separation method and device of the present invention are not limited to the following content.

[0060] In addition, in this specification, components shown in "claims" and "summary of the invention" are marked with symbols corresponding to components shown in the embodiments for easy understanding of the claims. However, the components shown in the claims are by no means limited to the components of the embodiment.

[0061] The ultrasonic separation device for solutions of the present invention separates high-concentration specific solutions from solutions containing at least two substances. The present invention does not limit the solvent and solute of the solution, the solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com