Method for nitriding tunnel oxide film, method for manufacturing non-volatile memory device, non-volatile memory device, control program and computer-readable storage medium

A technology of non-volatile storage and tunnel oxidation, applied in the field of control programs and computer-readable storage media, to reduce traps, improve data retention characteristics, and suppress leakage currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

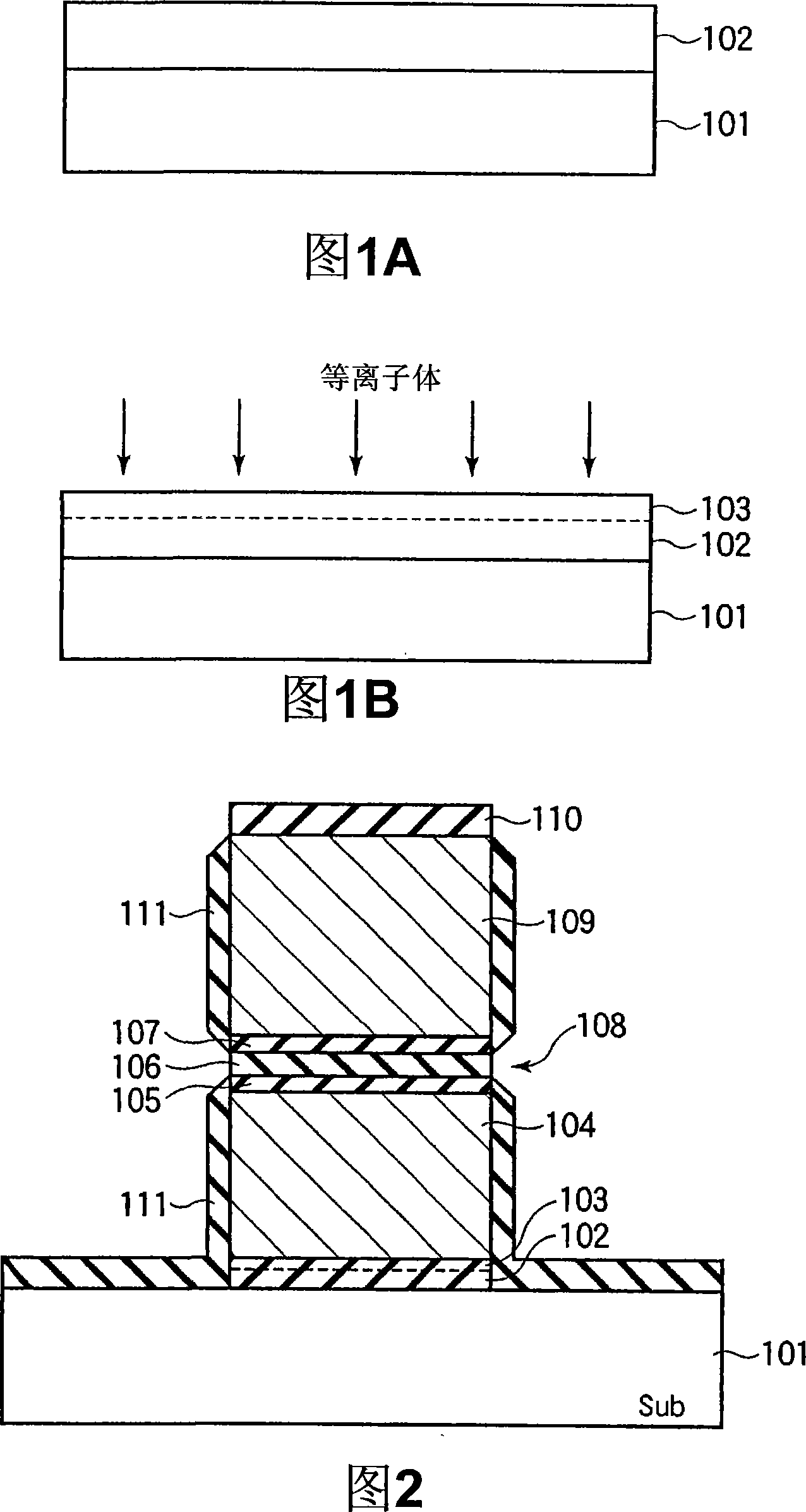

[0035] FIG. 1 is a cross-sectional view for explaining the method of nitriding a tunnel oxide film of the present invention. This nitriding process is part of the manufacturing process of non-volatile memory elements such as EPROM, EEPROM, and flash memory.

[0036] In the manufacturing of a memory cell of a nonvolatile memory element, first, as shown in FIG. 1A, a tunnel oxide film 102 with a thickness of about 10 nm is formed on the main surface of the Si substrate 101 by, for example, a thermal oxidation process of the Si substrate 101, and then In the main surface area of the Si substrate 101, predetermined ions are implanted, and then the tunnel oxide film 102 is nitridated. The nitriding treatment uses a gas containing nitrogen for plasma treatment, so that, as shown in FIG. 1B, a nitriding region 103 is formed on the surface portion of the tunnel oxide fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com