Mutton tenderizing agent

A technology of tenderizer and mutton, which is applied in application, food preparation, food science, etc. It can solve the problems of limited use, inability to hydrolyze connective tissue fibers, etc., and achieve the effect of safe use, good tenderness and reasonable preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples illustrate the present invention further:

[0032] Included in this embodiment are 1.2 parts of sodium pyrophosphate, 2.6 parts of sodium tripolyphosphate, 1.2 parts of sodium hexametaphosphate and 1.6 parts of calcium chloride.

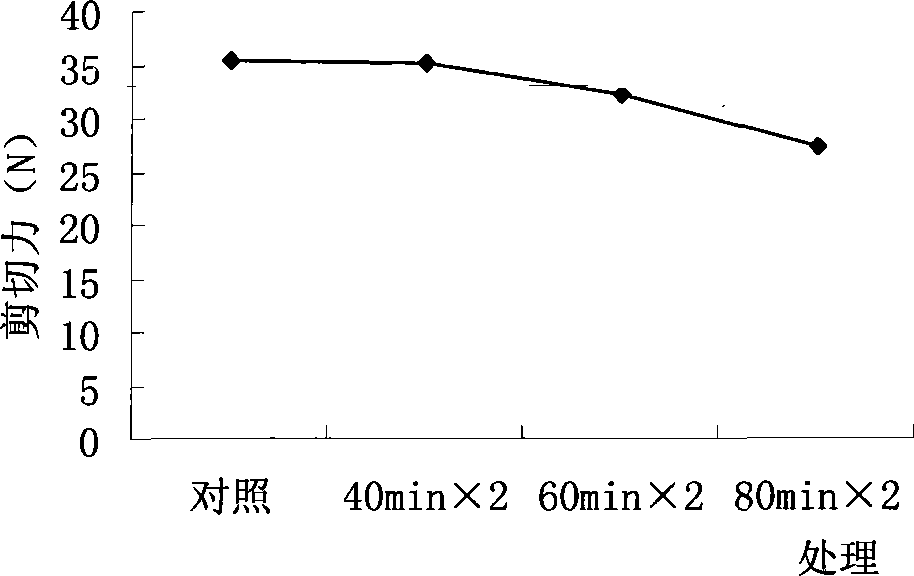

[0033] When using, firstly mix sodium pyrophosphate, sodium tripolyphosphate, sodium hexametaphosphate and calcium chloride thoroughly, and prepare the tenderizer with drinking water at an amount of 4.0 grams per kilogram of mutton tenderizer. % solution, as evenly as possible, injected into the mutton, and then divided into two continuous tumbling massages, tumbling for 80 minutes each time, with an interval of 24 hours between two tumbling and kneading. Combined with the accompanying drawings, it was finally verified that the shear force was reduced by about 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com