Automatic control turbine synchronous discharging-suction pump

A technology of suction pump and pump body, which is applied in the field of self-controlled turbine synchronous suction pump, which can solve the problems of large floor area, easy corrosion and leakage of bottom valve, long exhaust time, etc., to save investment, land occupation, and energy saving The effect is obvious and the suction loss is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

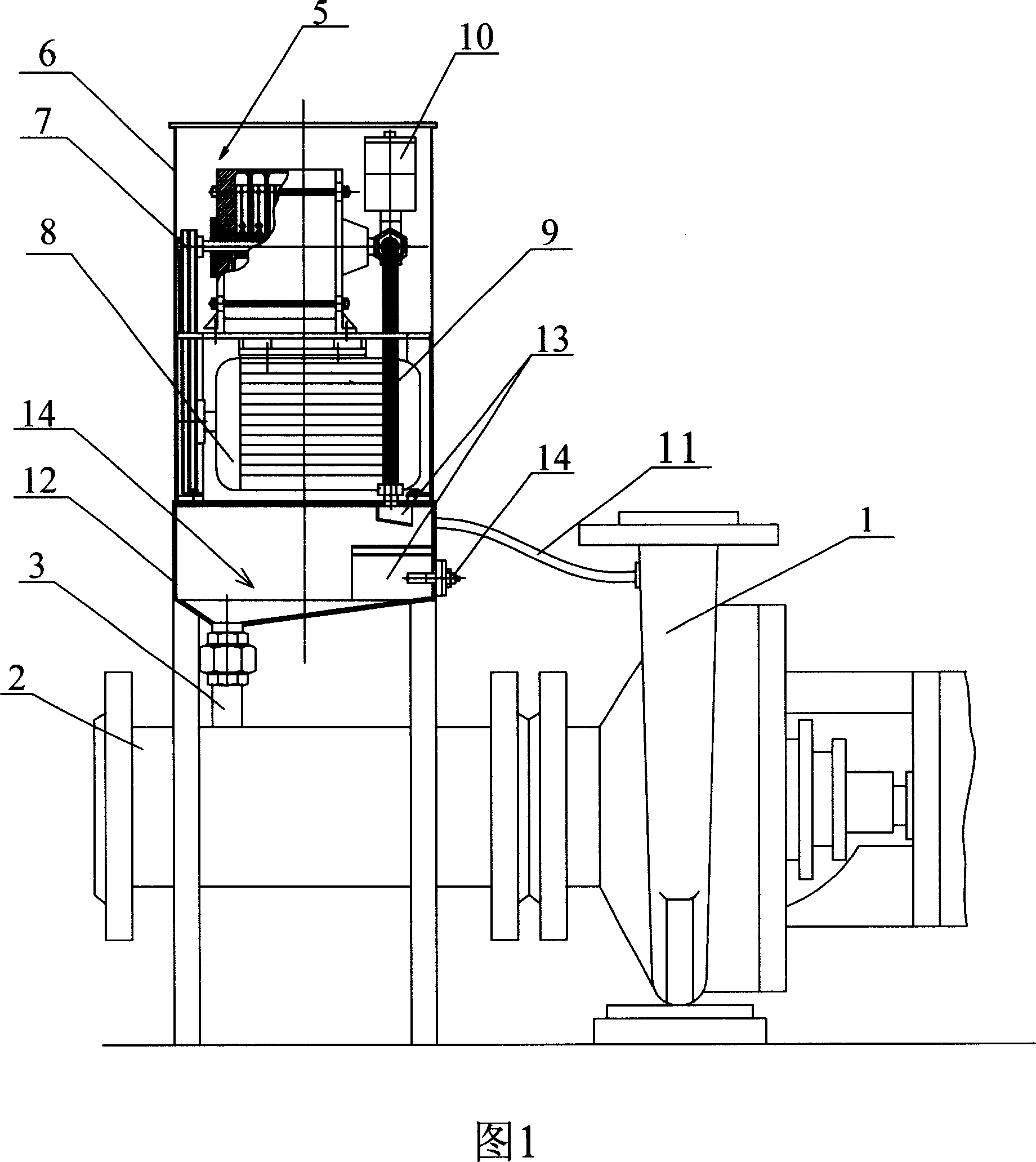

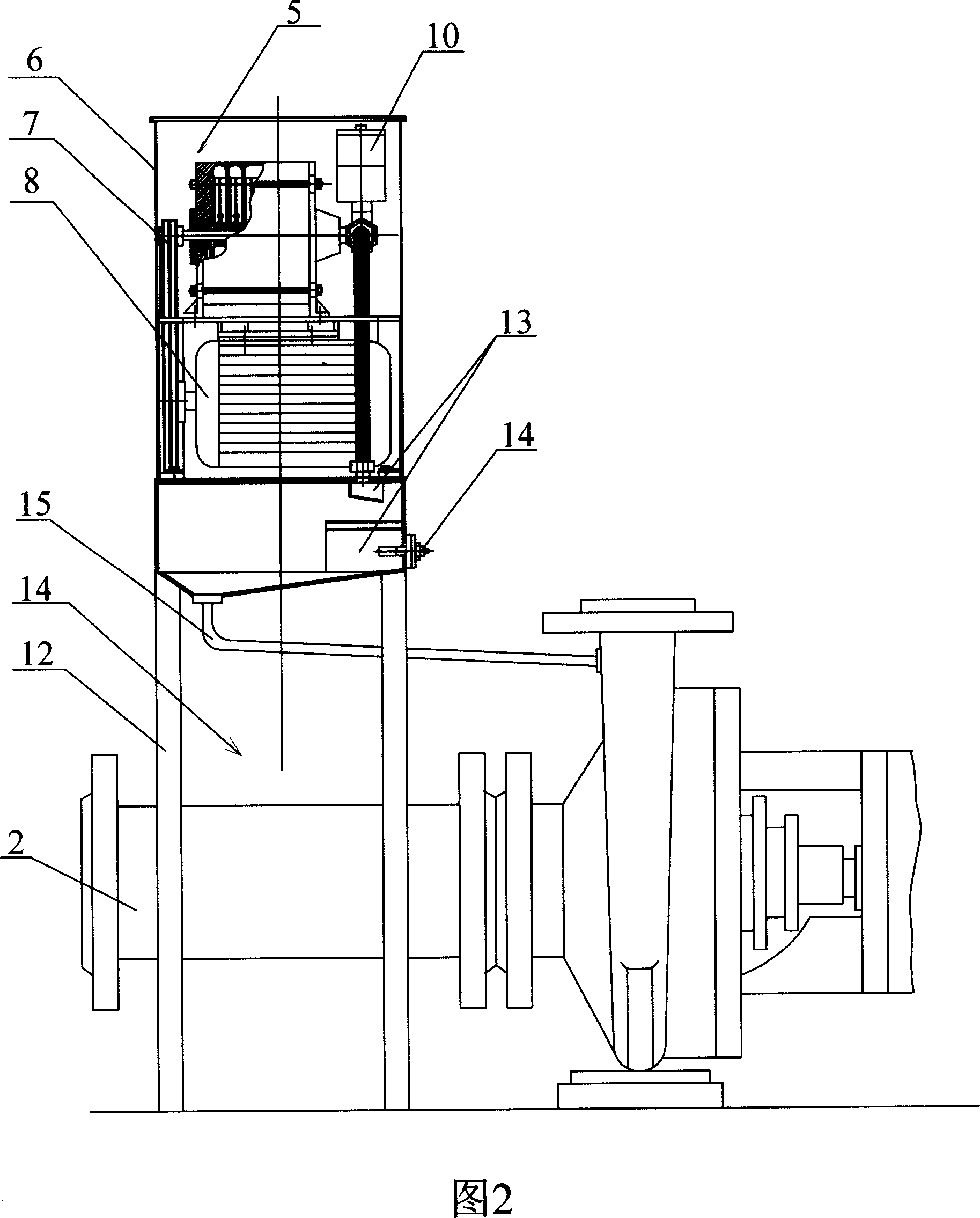

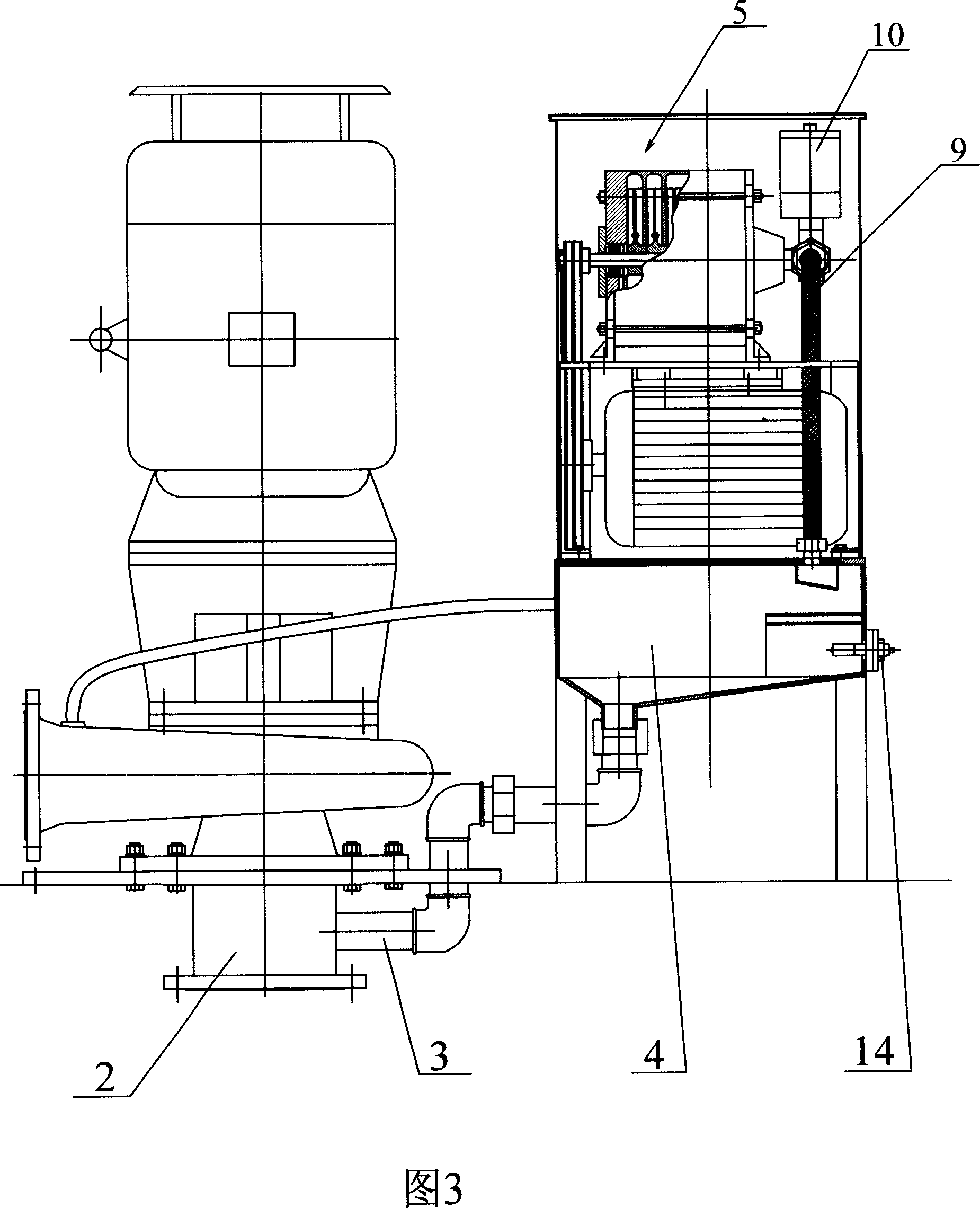

[0034] The self-controlled turbine synchronous exhaust-suction pump includes a delivery pump 1 and a suction connection 2, the rear end of the suction connection 2 is airtightly connected to the suction port of the delivery pump 1, and the gas-liquid separator 4 is arranged on a negative pressure device 5 . There is an air suction port at the bottom of the gas-liquid separator 4, and the air suction port is connected with the suction connecting pipe 2 through a suction pipe 3, and communicated with each other. A pressure balance pipe 11 is connected between the gas-liquid separator 4 and the inner cavity of the delivery pump 1 . The negative pressure device 5 includes a vacuum blower 7 and a motor 8 in which the casing 6 is arranged. The vacuum fan 7 adopts a single-stage centrifugal fan, and the conveying pump 1 is a vane type. There is a connecting pipe 9 between the negative pressure device 5 and the gas-liquid separator 4, and a vacuum solenoid valve 10 is installed on th...

Embodiment 2

[0036] Embodiment two is basically the same as embodiment one, and its difference is that the suction port at the bottom of the gas-liquid separator 4 communicates with the exhaust port on the delivery pump 1 through a connecting pipe 15, and the bottom of the gas-liquid separator 4 The suction port is higher than the exhaust port on the top of the transfer pump 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com