Building wall phase change energy-storage type polymer thermal insulating mortar and preparation method thereof

A technology for building thermal insulation mortar and phase change energy storage, which is applied in solid waste management, chemical instruments and methods, ceramic products, etc. To solve the problems of promotion and application, to achieve the effect of thermal insulation performance and temperature difference adjustment function, solve the effect of stable cycle work performance and high heat storage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

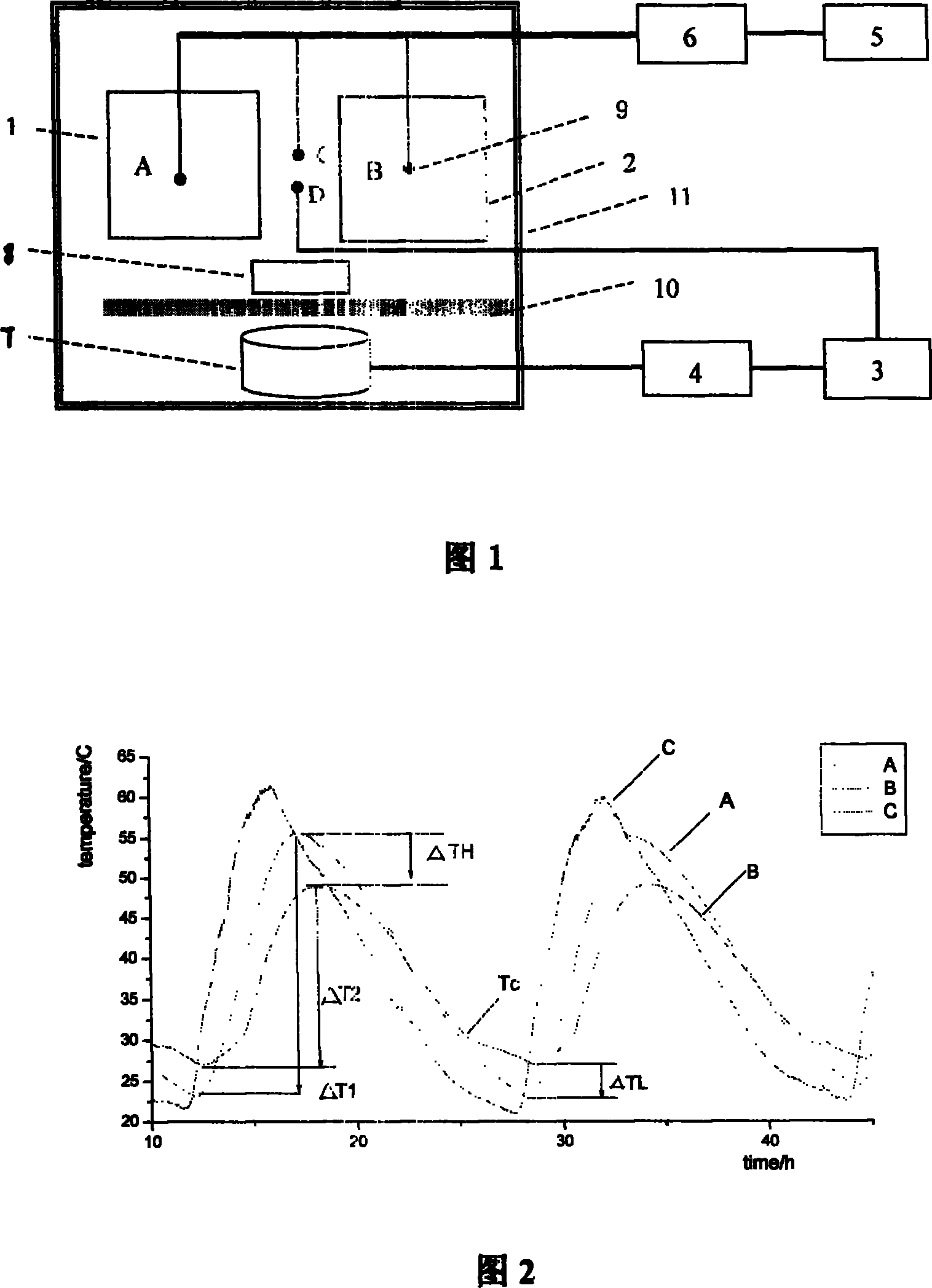

Image

Examples

Embodiment 1

[0040] Preparation of building wall phase change energy storage polymer insulation mortar;

[0041] A. The preparation of the phase-change energy storage aggregate, the porous medium material expanded perlite particles are selected, and the porosity of the expanded perlite particles is 80%. In a vacuum reactor or other containers, the porous medium material expanded perlite particles, organic Phase change material paraffin is mixed uniformly at a mass ratio of 1:5 at a temperature of 180°C; slowly open the vent valve, reduce the vacuum in the reactor to normal pressure, dissolve and evenly wrap the porous medium material on the surface of expanded perlite particles The organic phase change material paraffin completely absorbs and penetrates into the internal pores of the expanded perlite particles of the porous medium material; cooling down and unloading, it is the phase change energy storage aggregate;

[0042] B. Preparation of building wall phase-change energy-storage polym...

Embodiment 2

[0044] Preparation of building wall phase change energy storage polymer insulation mortar;

[0045] A. For the preparation of phase change energy storage aggregate, light-weight sintered ceramsite particles of porous medium materials are selected, and the porosity of light-weight sintered ceramsite particles is 50%. Sintered ceramsite particles and organic phase change material octanoic acid are mixed evenly at a mass ratio of 1:2 at a temperature of 50°C; slowly open the vent valve, reduce the vacuum in the reactor to normal pressure, dissolve and evenly wrap the porous medium material The organic phase-change material octanoic acid on the surface of the light-weight sintered ceramsite particles is completely absorbed and penetrated into the internal pores of the porous medium material light-weight sintered ceramsite particles; the temperature is lowered and the material is unloaded, which is the phase-change energy storage aggregate;

[0046] B. Preparation of building wall ...

Embodiment 3

[0048] A. The preparation of the phase change energy storage aggregate, the porous medium material fly ash ceramsite particles are selected, and the porosity of the light fly ash particles is 30%, and the porous medium material pulverized coal is placed in a vacuum reactor or other containers Gray ceramsite particles and organic phase change material fatty acids are mixed evenly at a mass ratio of 1:1 at a temperature of 100°C; slowly open the vent valve, reduce the vacuum in the reactor to normal pressure, dissolve and evenly wrap the porous medium material The fatty acid of the organic phase change material on the surface of the fly ash ceramsite particles is completely absorbed and penetrated into the internal pores of the porous medium material fly ash ceramsite particles; the temperature is lowered and the material is unloaded, which is the phase change energy storage aggregate;

[0049] B. Preparation of building wall phase-change energy-storage polymer thermal insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com