Radiation sensitive composition for forming a colored layer, color filter and color liquid crystal display device

A sensitive, radiation-sensitive technology used in the field of radiation-sensitive compositions to solve problems such as pattern edge defects or side etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0291] Examples are given below to further illustrate the present invention in detail. The present invention is not limited by the following examples. Here, parts are based on weight.

[0292]

Synthetic example 1

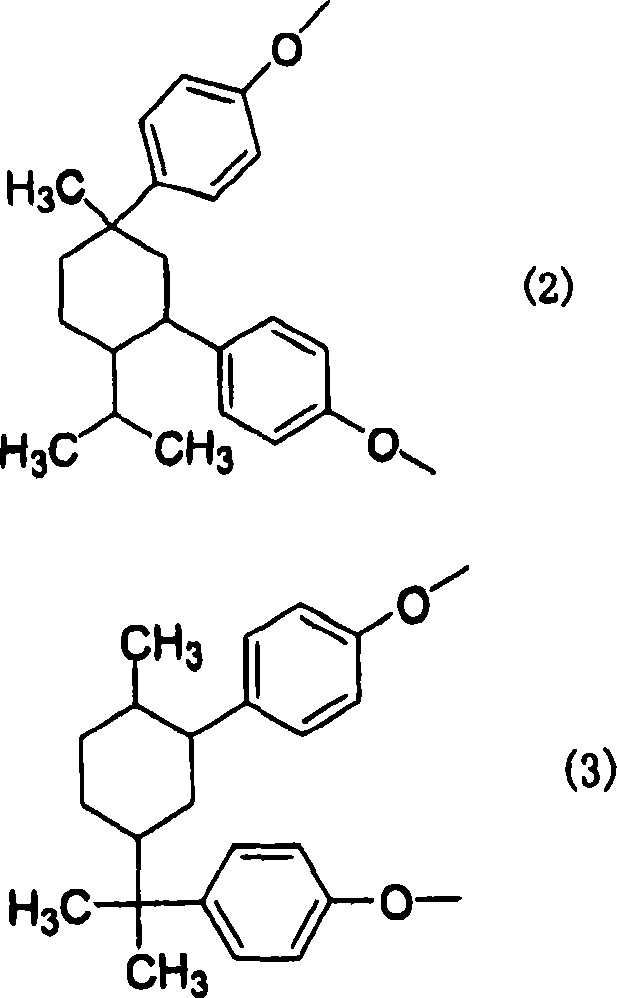

[0293] Synthesis Example 1 (Synthesis of diglycidyl etherate of diphenol)

[0294] Add 1,070 g of a mixture of diphenol (9): diphenol (10) = 70:30 (weight ratio) (trade name YP-90, manufactured by Mass Harak Mikar Co., Ltd.), 1520 g into a flask equipped with a condenser and a stirrer Epichlorohydrin and 1,700 g of dimethyl sulfoxide were heated to 50°C while stirring to dissolve, then 290 g of caustic soda was added and reacted at 65-90°C for 10 hours. The epoxy equivalent is measured to confirm the progress and end point of the reaction. When the epoxy equivalent reaches the target value, the solvent is distilled off under reduced pressure at 90-100°C. Then the reaction product was re-dissolved in toluene at 50-70°C, washed with distilled water and separated by standing, and then the organic layer was desolventized under reduced pressure to obtain 1260 g of reaction product. The epoxy equivalent of the obtained reaction product was 260.

[0295] Determination of the reaction pro...

Synthetic example 2

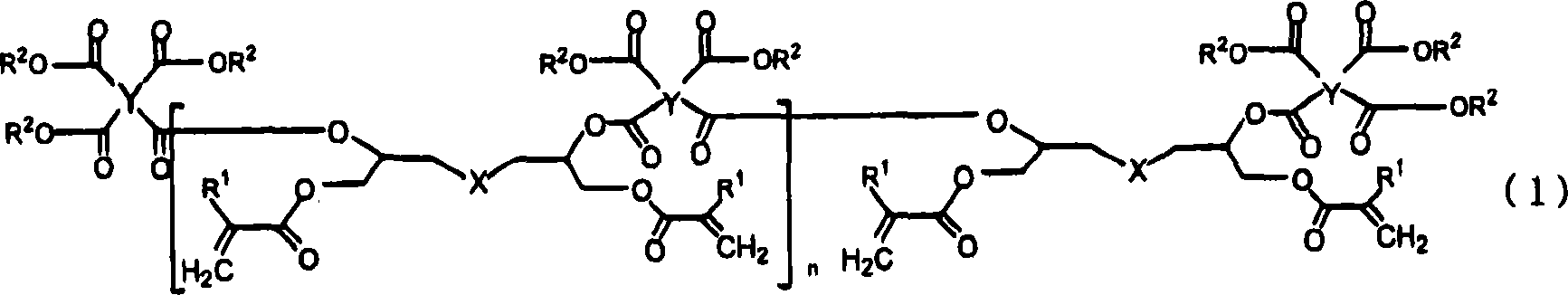

[0298] Synthesis example 2 (Synthesis of dimethylacryloyl-containing diol compound)

[0299] Into a flask equipped with a condenser and a stirrer, 1000 g of the diglycidyl ether compound obtained in Synthesis Example 1, 350 g of methacrylic acid, and 1.0 g of hydroquinone monomethyl ether were added, and heated to 60°C while stirring to dissolve it. Then add 8g of tetraethylammonium bromide and continue the reaction while stirring at 70-90°C until the acid value of the reaction product is 8mgKOH / g and the epoxy equivalent is 17,000. After 15 hours, the end point is confirmed by the acid value and epoxy equivalent. , And then cooled to room temperature to obtain 1,300 g of reaction product. The acid value of the obtained reaction product was 8 mgKOH / g, the hydroxyl value was 165 mgKOH / g, and the epoxy equivalent was 17,000.

[0300] For the reaction product, determine 1 H-NMR spectrum, visible chemical shift δ (ppm) at 5.6 and 6.1 (from the double bond of methacrylic acid; 4H), 3.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com