Polymerization inhibitor for 1,3-butadiene and a method of inhibiting polymerization of 1,3-butadiene by imputing thereof

A technology of polymerization inhibitor and butadiene, applied in chemical instruments and methods, excavation, hydrocarbons, etc., can solve the problems of factory operation interruption, equipment explosion, huge factory cost, etc., and achieve excellent polymerization inhibition effect, Stable operation, excellent fouling prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

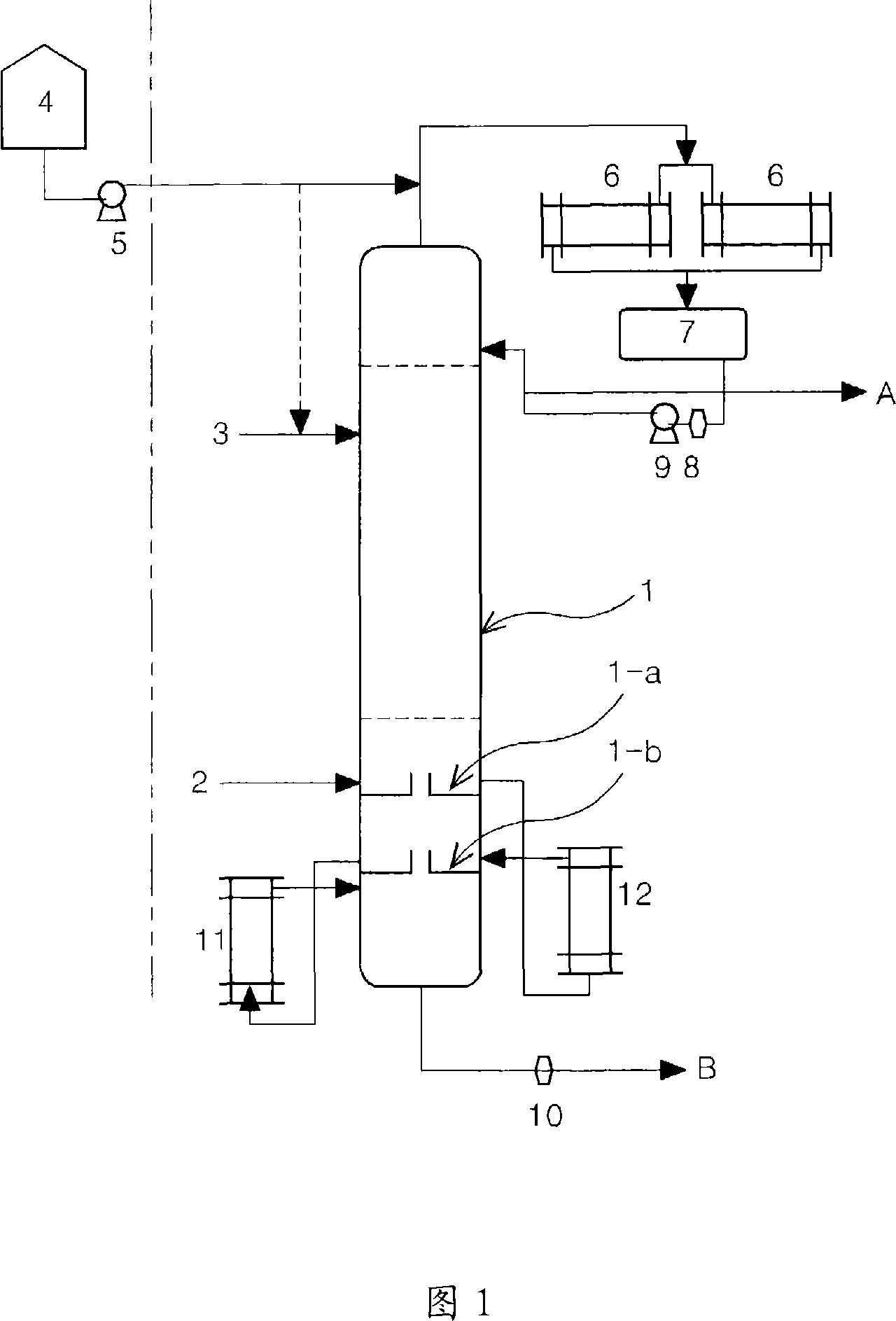

Method used

Image

Examples

Embodiment 1

[0072] Relative to the total amount of C4 mixture introduced, 30 ppm of polymerization inhibitor containing 15wt% of TBC, 75wt% of DEHA and 10wt% of IBA enters the extractive distillation pump including liquid phase and gas phase through the feed pump for polymerization inhibitor And periodically evaluate to check the condition and amount of polymer accumulation. The results are shown in Table 1.

Embodiment 2

[0074]Except that the composition and mixing ratio of the polymerization inhibitor were changed so that the polymerization inhibitor contained 15 wt% TBC, 75 wt% DEHA, and 10 wt% IPA, the state and amount of polymer accumulation were periodically checked in the same manner as in Example 1. The results are shown in Table 1.

Embodiment 3

[0076] Except that the composition and mixing ratio of the polymerization inhibitor were changed so that the polymerization inhibitor contained 15 wt% BHT, 75 wt% DEHA, and 10 wt% IPA, the condition and amount of polymer accumulation were periodically checked in the same manner as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com