Plasma resonant cavity waveguide assembly with heat insulating function

A plasma and waveguide device technology, applied in gaseous chemical plating, metal material coating technology, coating, etc., can solve problems affecting the effective service life of microwave generators, damage microwave generators and their supporting devices, etc., to achieve Easy to implement, enhance the effect of cutting off heat radiation, and facilitate the effect of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

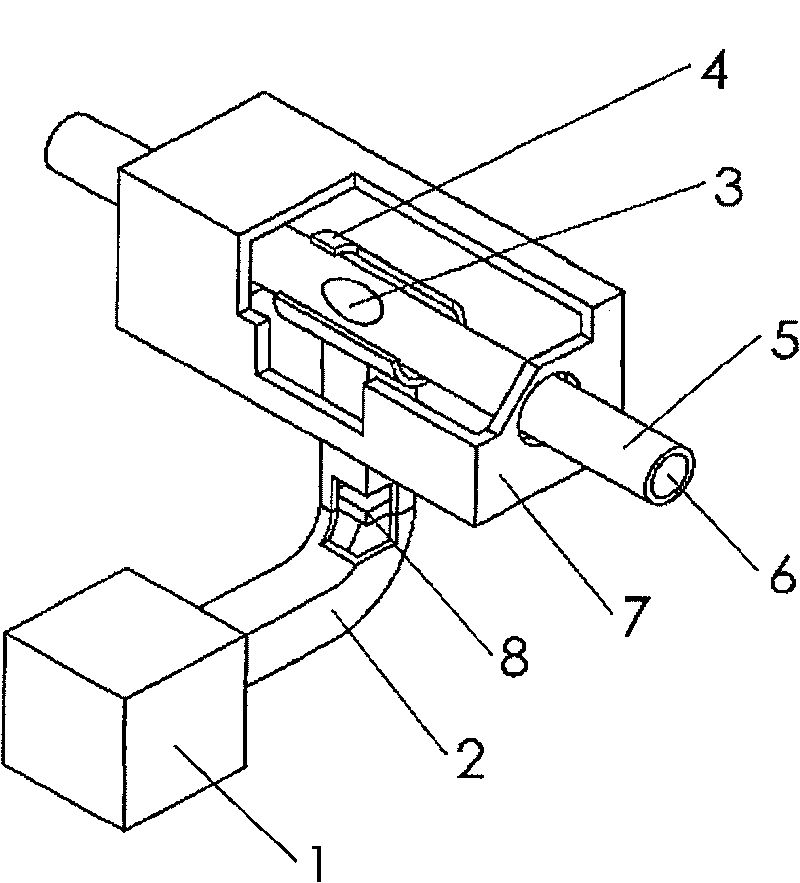

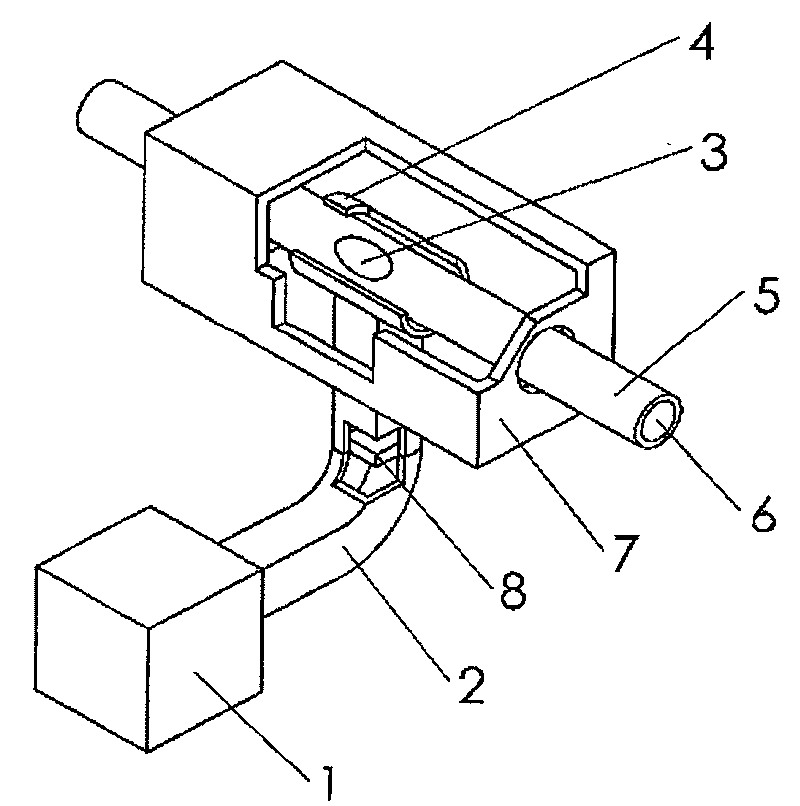

[0010] Further illustrate the embodiment of the present invention below in conjunction with accompanying drawing, comprise microwave generator 1, be equipped with automatic tuner in the microwave generator, microwave generator and rectangular waveguide 2 one ends join, rectangular waveguide comprises the rectangular waveguide that is arranged horizontally and A rectangular waveguide that is vertically bent and extended upwards. The cross section of the rectangular waveguide is rectangular. Below the vertically arranged rectangular waveguide, there is a heat shield 8 that traverses the cross section of the waveguide inner cavity. The heat shield is made of high temperature resistant non-metallic material, and can be selected Aluminum silicate refractories or ceramic materials with a metal impurity content of less than 0.01% are used to cut off heat radiation without affecting the transmission of microwaves. The cross-sectional shape and size are the same, and the heat shield can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com