Optical fiber temperature sensor based on bending loss

A technology of optical fiber temperature and bending loss, which is applied in the field of sensors, can solve the problems of complex optical signal detection devices, many coupling devices, and high production costs, and achieve the effects of light weight, small volume, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the present invention will be further described in detail by the given examples below.

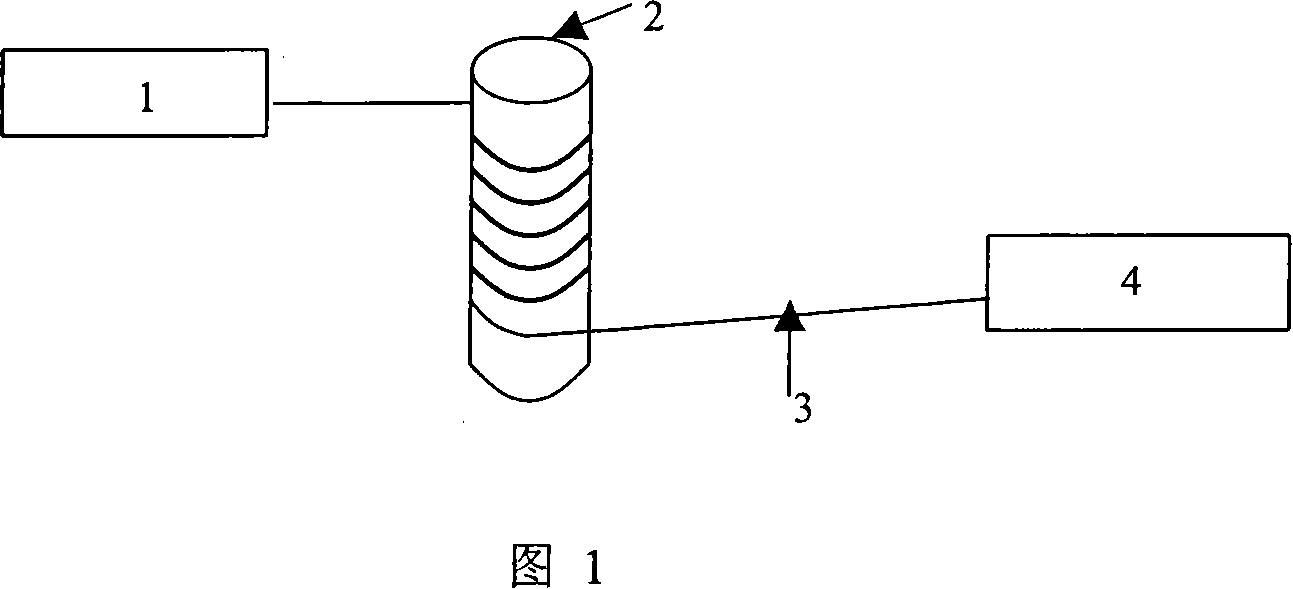

[0018] Referring to Figure 1, select a multimode step-type optical fiber 3 with a core diameter of a=50um and a numerical aperture of NA=0.4; use optical fiber pliers to peel off the outer coating layer at both ends of the optical fiber; use an optical fiber cleaver to cut both ends of the optical fiber neatly plane; use FC-type bare fiber adapters (not shown in the figure) to fix the two ends of the optical fiber; select a glass rod 2 with a radius of 3.5 mm and a height of 1 mm for use; evenly coat a layer of UV curing on the surface of the clean glass rod 2 Glue, tightly wind the optical fiber several times on the glass rod 2 (in order to facilitate the observation, the optical fiber is sparsely arranged in the attached drawing), and irradiate the UV curing glue with an ultraviolet lamp to bond the glass rod and the optical fiber; connect the two ends of the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com