Thin-film transistor, pixel structure and LCD panel

A thin-film transistor and pixel structure technology, which is applied in the field of liquid crystal display panels, can solve problems such as cost increase, and achieve the effect of reducing cost and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

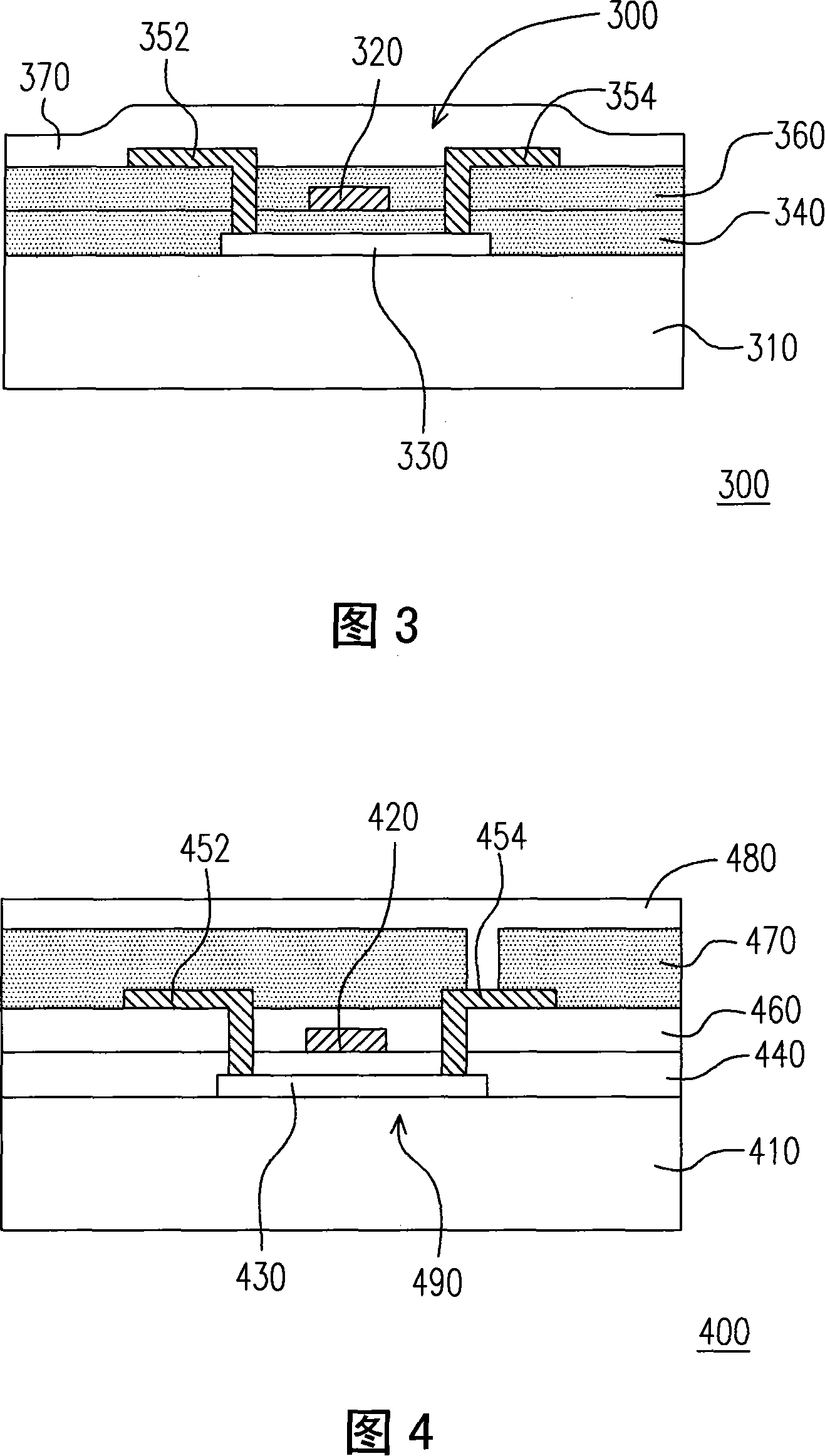

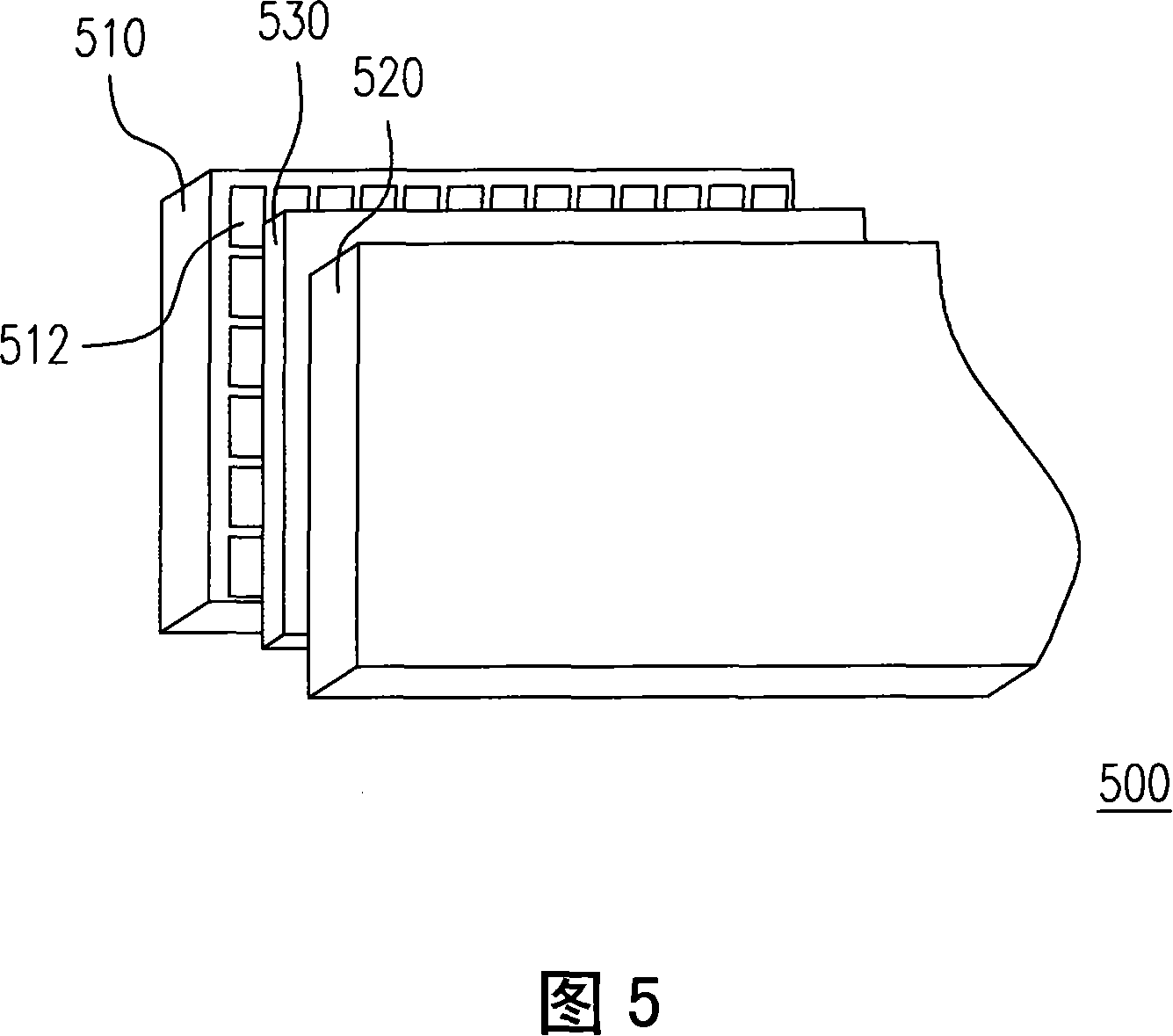

[0068] In the known thin film transistors, one or more insulating layers must be arranged to electrically insulate the gate from the source, drain and channel layers. Since there are various insulating materials that can convert light and filter light, the present invention proposes to use insulating materials that can make light appear in different colors to fabricate the insulating film layer of the thin film transistor and the pixel structure. In this way, the light can present a specific color after passing through the thin film transistor, pixel structure and related elements or display device of the present invention.

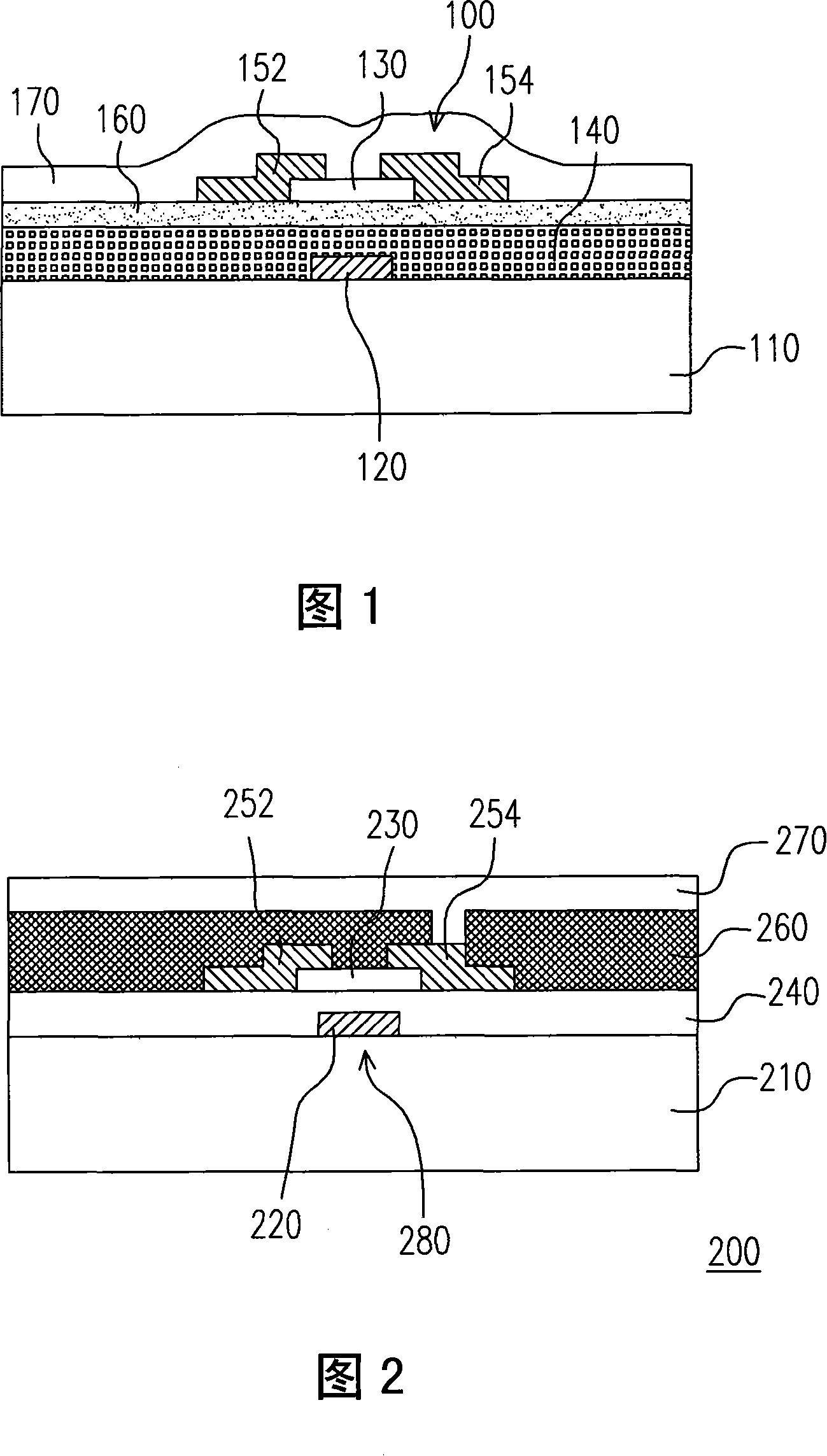

[0069] FIG. 1 shows a thin film transistor of an embodiment of the present invention. Referring to FIG. 1 , the thin film transistor 100 is disposed on a substrate 110 . The thin film transistor 100 includes a gate 120 , a semiconductor layer 130 , a gate insulating layer 140 , and a source 152 and a drain 154 . The gate insulation layer 140 is located ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com