Method and apparatus for producing three-dimensional structure

A technology of three-dimensional structure and manufacturing method, which is applied in the direction of microstructure devices, manufacturing microstructure devices, microelectronic microstructure devices, etc., and can solve problems such as inapplicable, difficult to realize, and incapable of three-dimensional stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

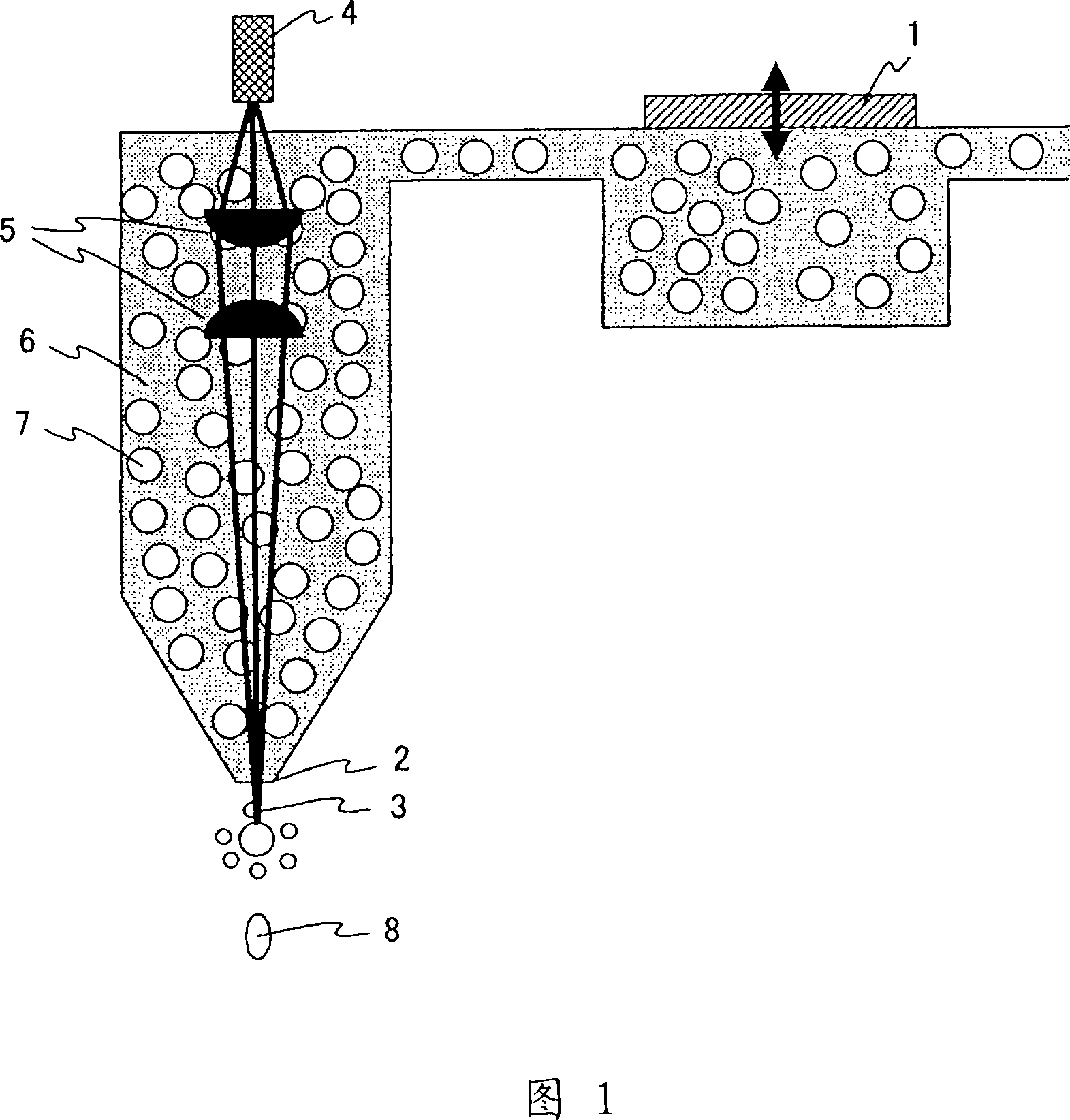

[0078] FIG. 1 shows an example of an inkjet head, which is a part of an apparatus for manufacturing a three-dimensional structure. 1 denotes a piezoelectric element, 2 denotes a nozzle, 3 denotes a laser, 4 denotes a laser, 5 denotes a lens, 6 denotes a solvent, 7 denotes a polymer particle, and 8 denotes a liquid droplet whose viscosity has been increased.

[0079] The piezoelectric element 1 is vibrated at a high speed, and the solvent 6 and the polymer particles 7 are ejected from the nozzle 2 as droplets. Laser light 3 is oscillated from laser 4 (for example, YAG laser, semiconductor laser, or ultraviolet laser, etc.), and laser light 3 is converted into parallel light by lens 5, and then, the focal point of laser light 3 that has been converted into parallel light is focused on the nozzle. on the droplet.

[0080]Using a focused laser light, the ejected droplets are heated to evaporate the solvent and melt the polymer particles contained in the solution. As a result, th...

Embodiment approach 2

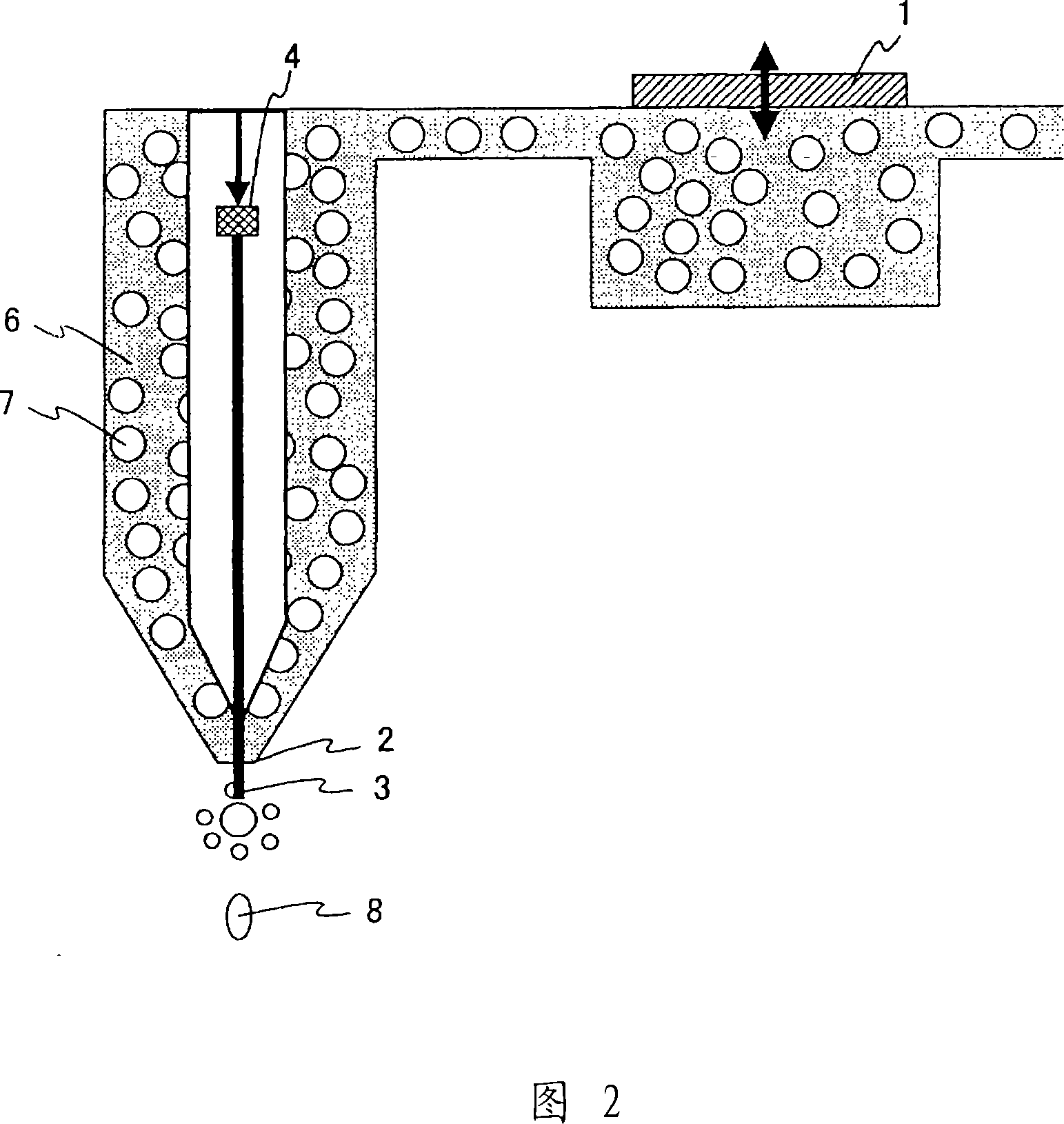

[0084] FIG. 2 shows another example of an inkjet head, which is a part of the apparatus for manufacturing a three-dimensional structure. In FIG. 2 , the same reference numerals are used for the same components as those in FIG. 1 , and explanations thereof are omitted.

[0085] The liquid droplets of the solution containing the polymer particles 7 are ejected by vibrating the piezoelectric element 1 provided in the inkjet head at high speed. The laser 4 is provided in a cylinder provided at a central position inside the inkjet head. Also, keep the solution from flowing into the cylinder.

[0086] In order to facilitate the ejection of the solution, gas may also flow out from a cylinder provided inside the inkjet head. The gas, which can be hot air, is used to change the viscosity of the sprayed liquid droplets.

[0087] When the laser 3 is irradiated on the ejected liquid droplets, the solvent (such as water) evaporates, and the polymer particles contained in the liquid drop...

Embodiment approach 3

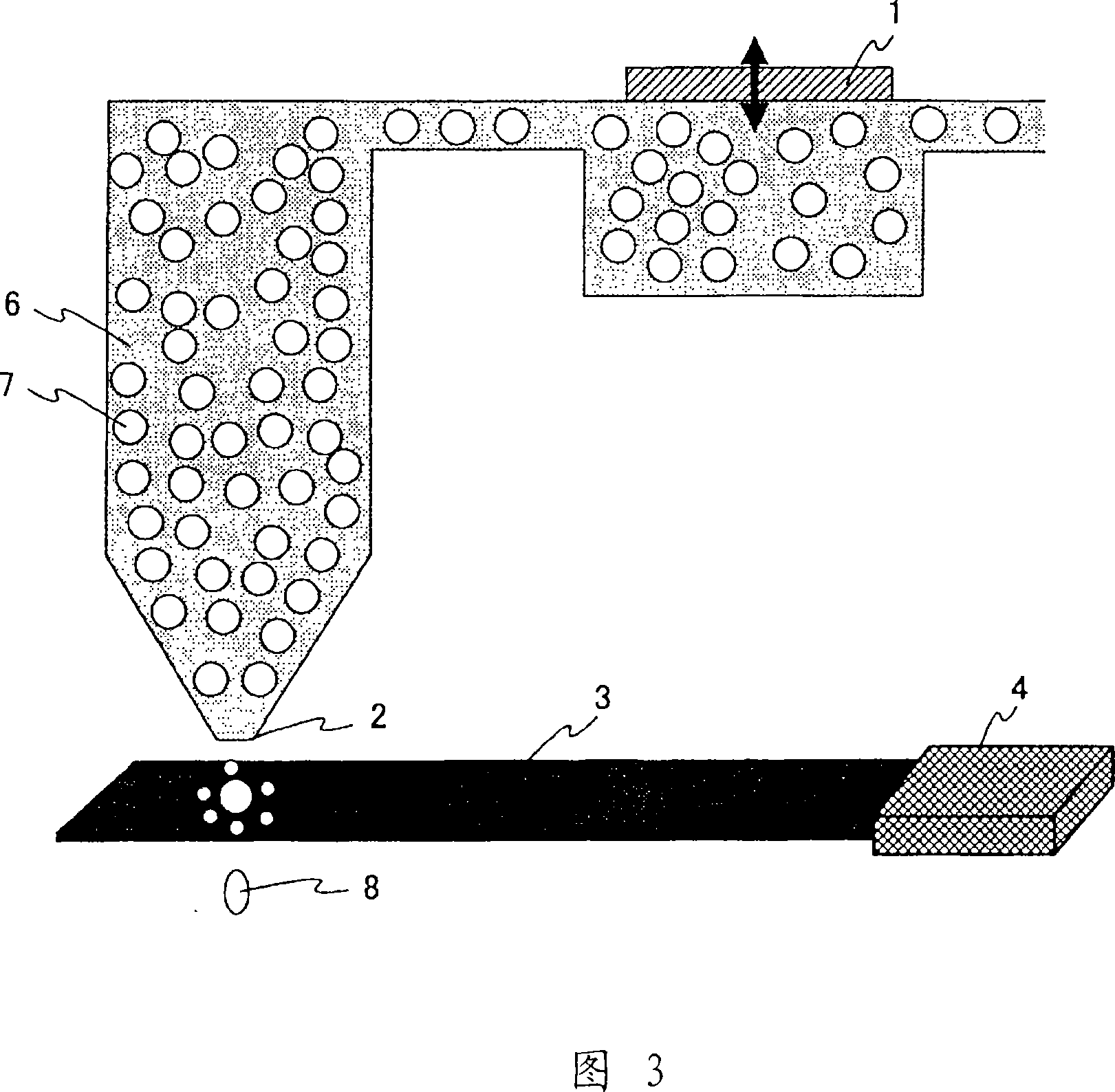

[0090] 3 and 4 show another example of an inkjet head, which is an apparatus for manufacturing a three-dimensional structure in the present invention. In FIGS. 3 and 4 , the same reference numerals are used for the same constituent elements as those in FIG. 1 , and description thereof will be omitted.

[0091] By vibrating the piezoelectric element 1 inside the inkjet device at high speed, droplets of the solution containing the polymer particles 7 can be ejected. The laser 4 is arranged outside the inkjet head. In FIG. 3 , it is arranged at a position substantially horizontal to the nozzle; in FIG. 4 , it is arranged at an oblique upper part of the nozzle. As shown in the figure, if the laser beam 3 has a planar shape, it is relatively easy to irradiate the ejected polymer particles.

[0092] At this time, it is also possible to condense the laser light and irradiate the liquid droplets containing the polymer particles from the side. When the ejected liquid droplets are irr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com