Method for modifying compound film surface

A surface modification and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as practical application limitations, achieve simple and safe operation, improve pollution resistance, and improve hydrophilicity and the effect of charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

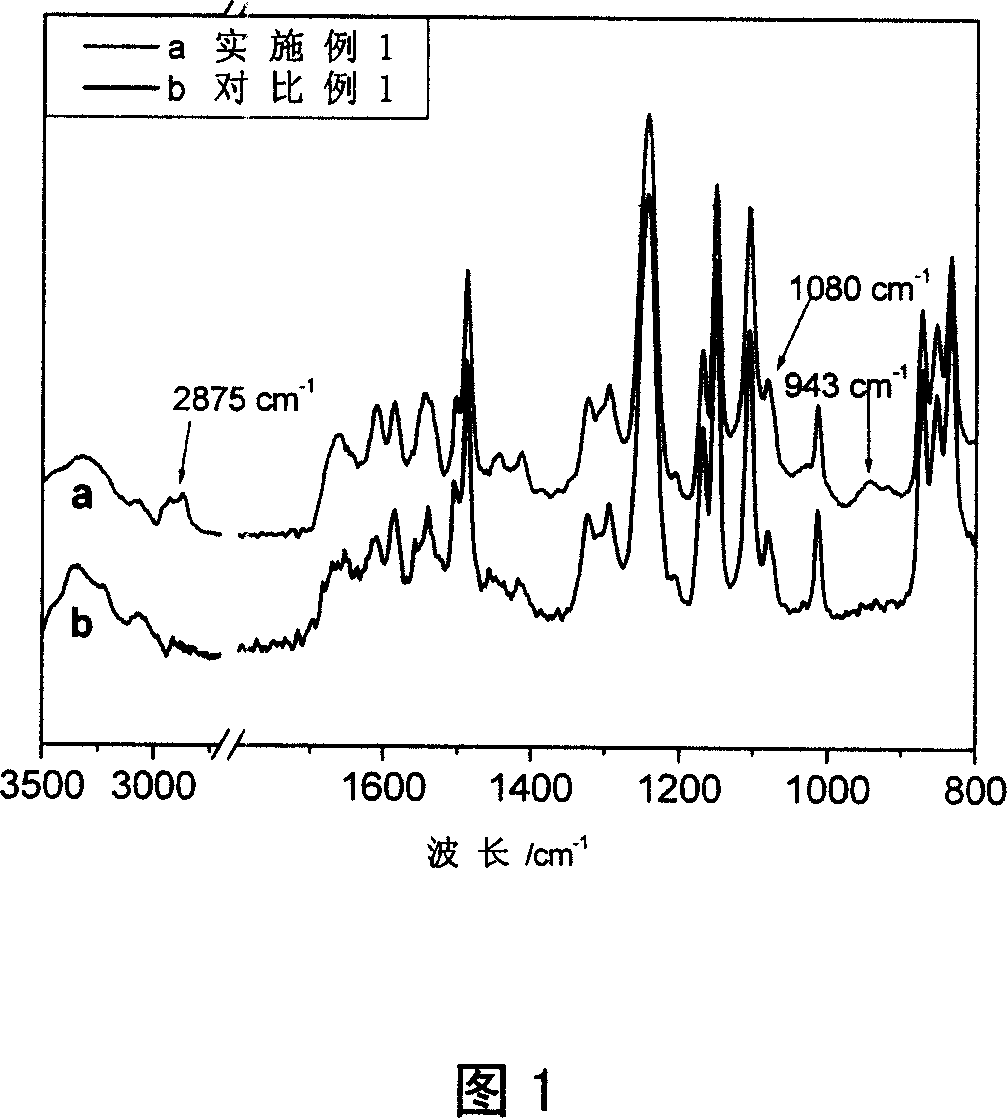

[0032] The N,N-dimethylacetamide (DMAc) solution with a polysulfone concentration of 17.5% and a methyl cellosolve concentration of 14% is made into a casting solution at 80°C, and scraped to a certain thickness on a glass plate after defoaming , hydrogel prepared support membrane. Soak the polysulfone support membrane in 2.0% m-phenylenediamine aqueous solution for 2 minutes, drain it and react it in 0.1% trimesoyl chloride for 1 minute, take out the membrane and let it dry slightly, then immerse it in 5% aminopolyethylene glycol monomethyl ether The aqueous solution of 10min, post-treatment at 60 ℃ for 5min. The prepared composite membrane was washed with deionized water and then tested for anti-fouling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com