Organic luminous component and manufacturing method therefor

A technology for a light-emitting component and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of increased manufacturing cost, complicated manufacturing of multi-layer structures, and interface reflection affects the luminous efficiency of components. Luminous efficiency, the effect of reducing interface reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

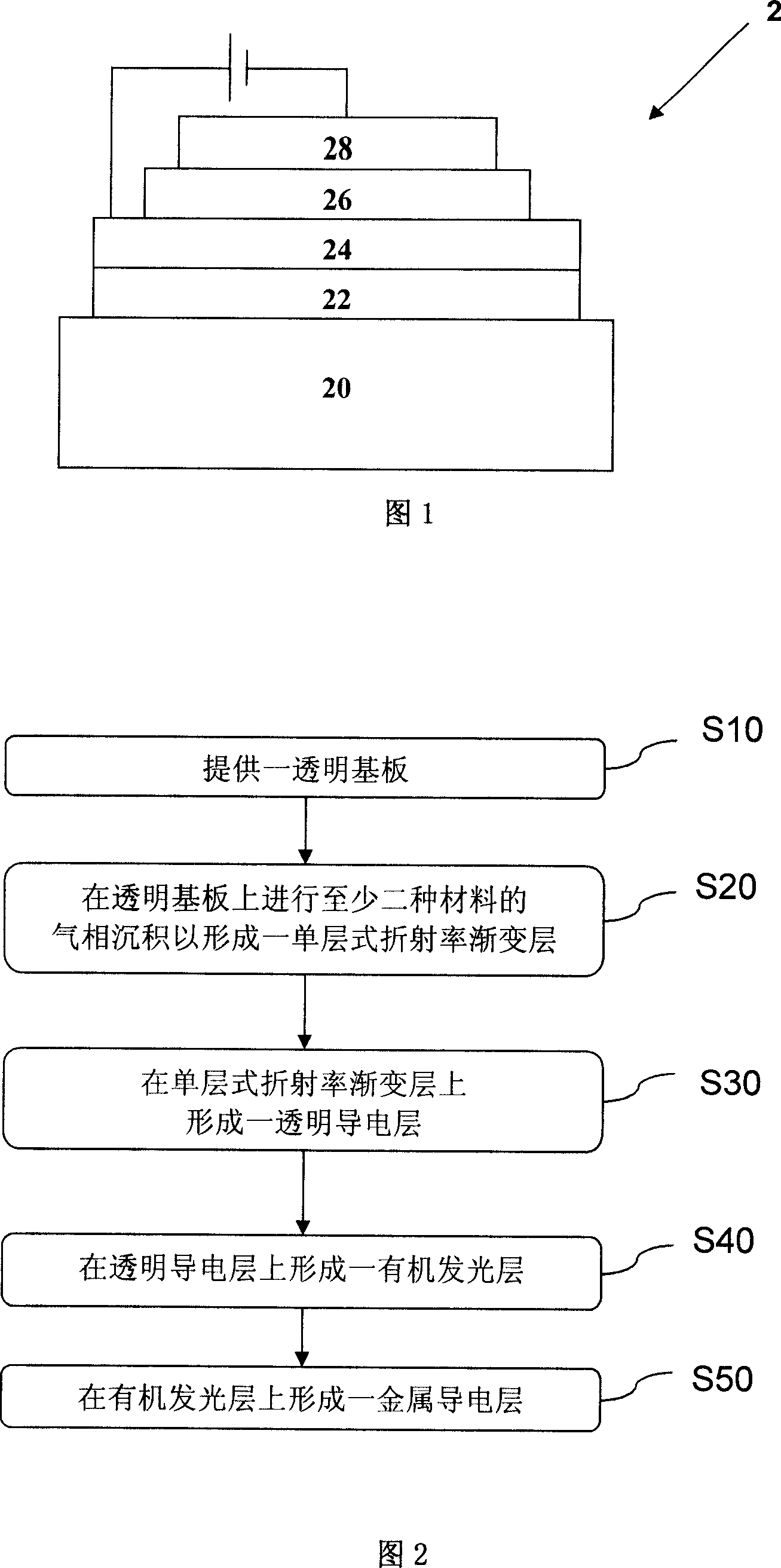

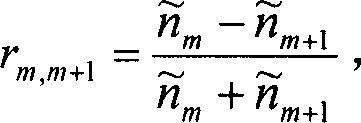

[0022] As shown in FIG. 1 , it is a schematic diagram of the three-dimensional structure of the organic light-emitting component of the present invention. The organic light-emitting component 2 includes a transparent substrate 20, which can be a glass substrate or a plastic substrate; a single-layer graded refractive index layer 22, which can be At least two materials are selected to be deposited on the transparent substrate 20 by vapor deposition. At least two materials may be composed of transparent conductive materials and at least one dielectric material with a low refractive index lower than 1.7, or at least one low refractive material with a refractive index lower than 1.7. The low refractive index dielectric material can be selected from silicon oxide, magnesium fluoride or calcium fluoride, and the high refractive index dielectric material can be selected from Titanium oxide, tantalum oxide or niobium oxide; a transparent conductive layer 24 located on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com