Triangle bended plate type piezoelectric straight line ultrasound electric motor

A linear ultrasonic motor, triangular technology, applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of high cost, complicated process, and many parts, and achieve The effect of low cost, small horizontal size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

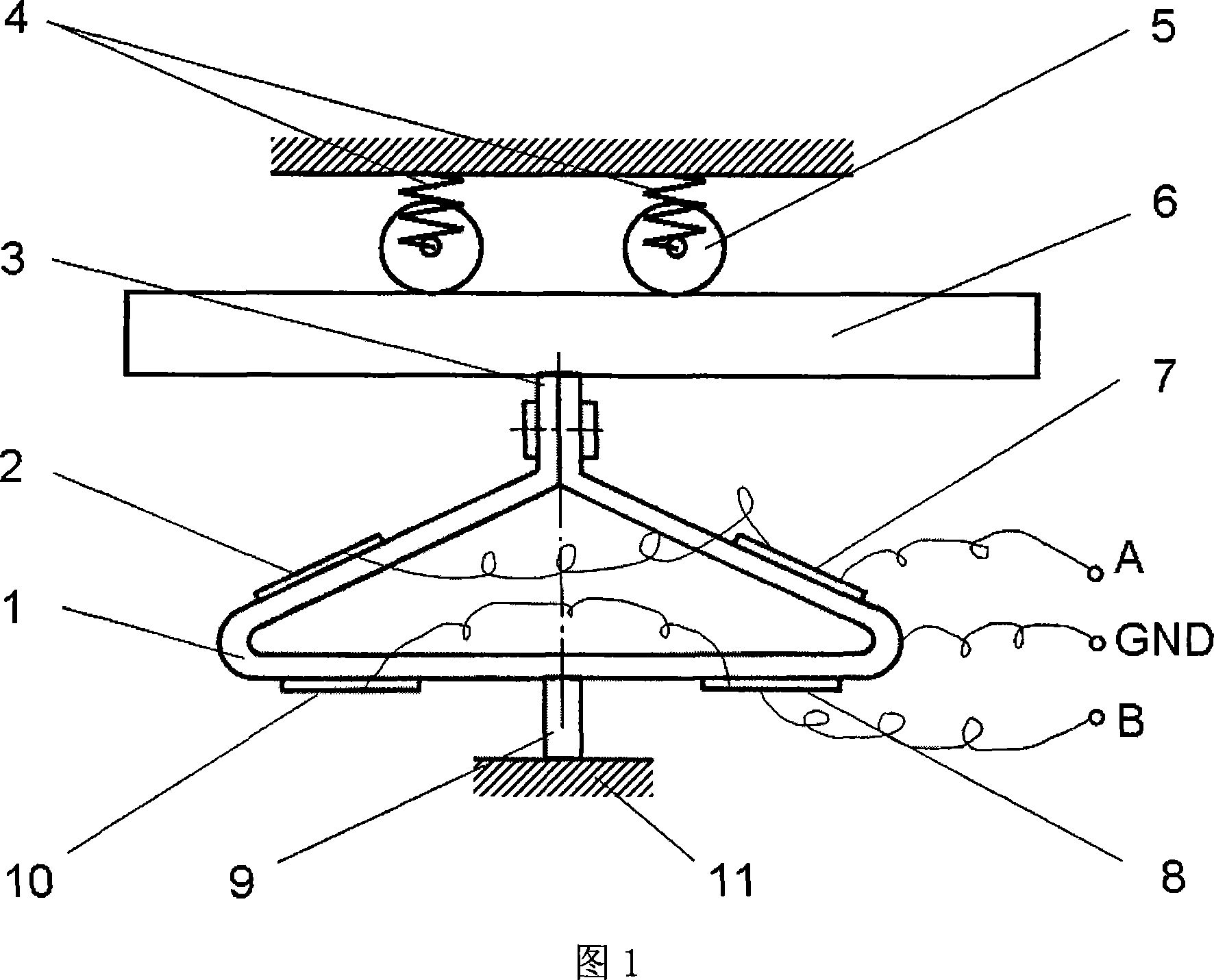

Embodiment 1

[0027] Referring to Fig. 1, the triangular bent-plate piezoelectric linear ultrasonic motor includes a stator and a mover, the mover is a linear guide rail 10, and the upper part is supported by two parallel guide wheels 5 with spring legs 4, while the lower part is supported by the stator , the stator consists of a hollow triangular elastic body frame 1 and piezoelectric actuators 2, 7, 8, 10 pasted on its outer surface. The elastic body can be carbon steel, hard aluminum alloy, copper and other metal materials, and can also be other non-metallic materials or composite materials with better elasticity and higher hardness. The piezoelectric actuator used is a piezoelectric ceramic sheet uniformly coated with silver electrodes on the upper and lower sides and polarized along the thickness direction, so the piezoelectric actuator is referred to as a piezoelectric ceramic sheet hereinafter. The stator is a left-right symmetrical structure. There is a raised portion 3 above the s...

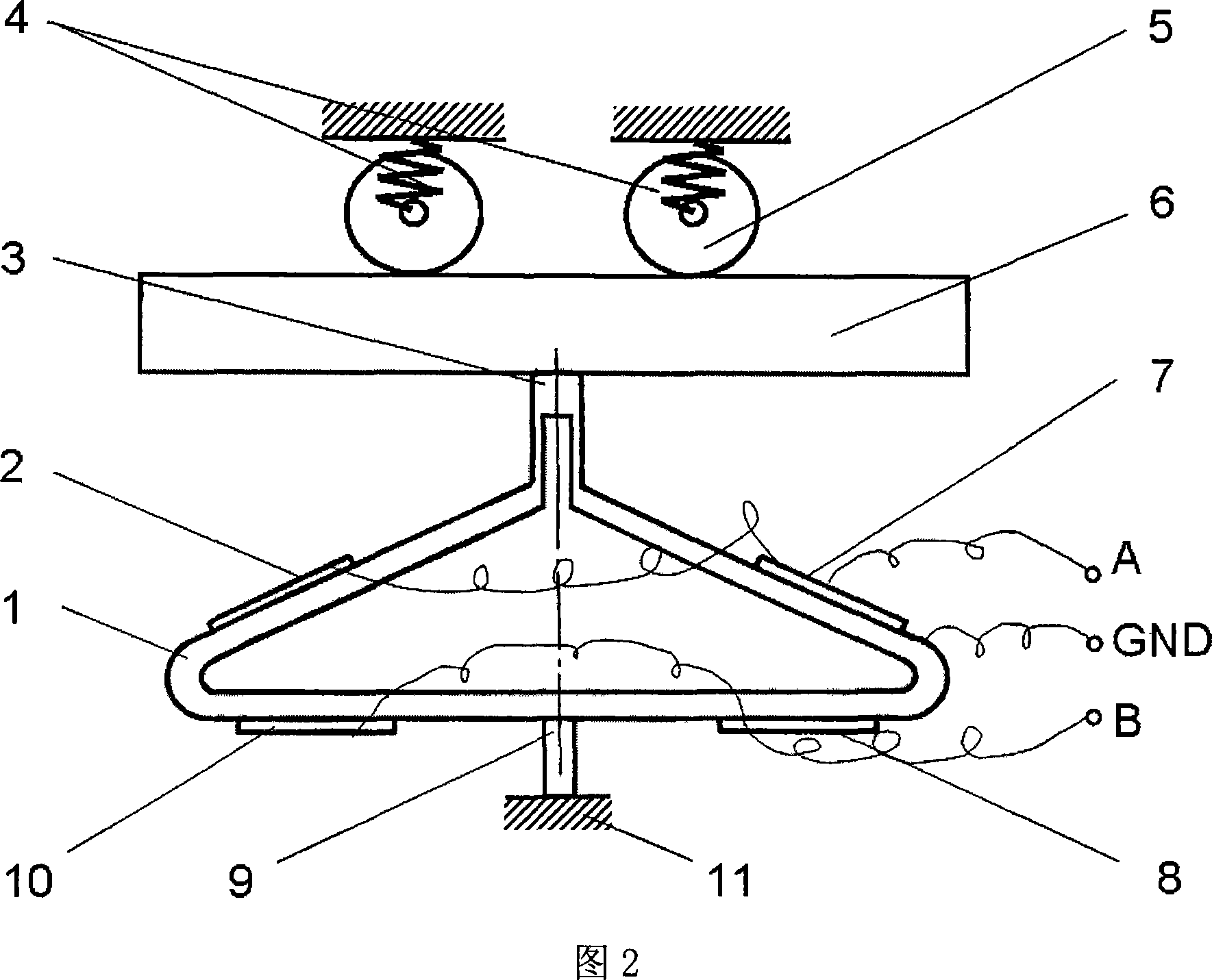

Embodiment 2

[0031] Referring to Fig. 2, the structure of the triangular bent-plate piezoelectric linear ultrasonic motor is basically the same as the above-mentioned embodiment, the difference is that the original mover becomes relatively stationary, while the original stator moves in a straight line, that is: the stator It is a linear guide rail (6) above which is supported by two guide wheels 5 with spring legs 4 arranged in parallel. The linear guide rail 6 is relatively horizontally positioned with the base 11. The mover is made of a hollow triangular elastic body frame 1 and pasted outside it. The piezoelectric actuators 2, 7, 8, 10 on the surface are composed, and the triangular vertex of the hollow triangular elastic body frame 1 has a raised part 3 that interferes with the bottom surface of the linear guide 6, and its triangular bottom has a clamper 9 slidingly supported on the base 11. The above-mentioned hollow triangular elastic body frame 1 is a block wire-cut molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com