Positioning embedded bricklaying

An embedded, bricklaying technology, applied in water conservancy projects, artificial islands, infrastructure projects, etc., can solve the problems of slow project progress, difficult to control project quality, unfavorable project costs, etc., to enhance longitudinal tension and lateral thrust, reduce The use of bonding materials, the effect of reducing the construction cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

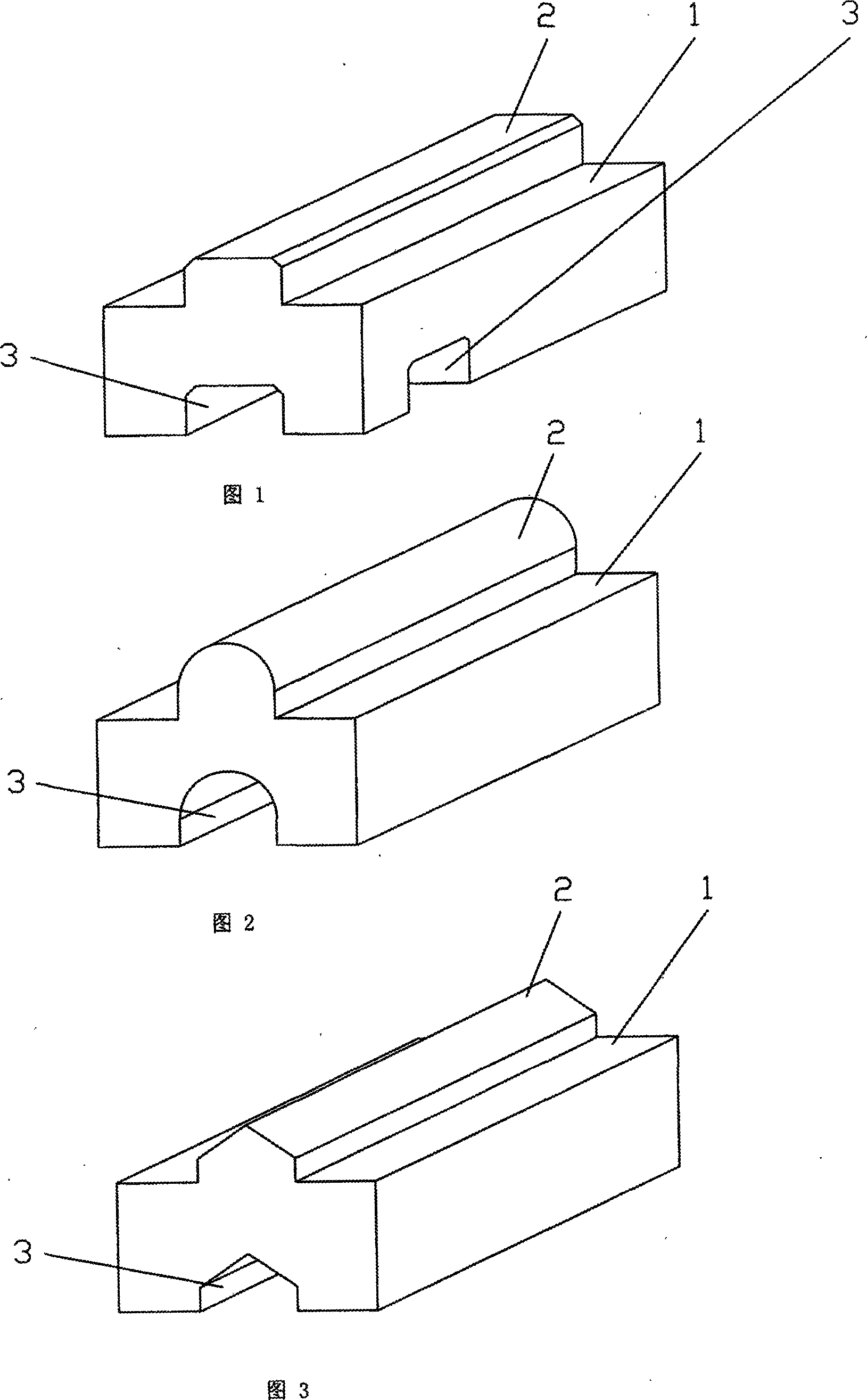

Embodiment 1

[0019] Embodiment 1: a kind of positioning embedded bricklaying, comprising existing brick-making materials and unburned bricks, fired bricks, hollow bricks, solid bricks, semi-hollow bricks and stone bricks made by existing production methods, on one side of the brick body 1 There is at least one "one" shape or "ten" shape or "well" shape or the convex body 2 of the table shape, and at least one "one" shape or "ten" shape is provided at the corresponding position on the other side of the brick body Or the groove 3 of " well " shape body or platform shape body, convex body 2 and groove 3 are rectangles among Fig. 1, convex body 2 and groove 3 are arcuate body among Fig. 2, convex body 2 and groove 3 among Fig. 3 The groove 3 is a triangle, and the protrusion 2 and the groove 3 are trapezoids in FIG. 4 .

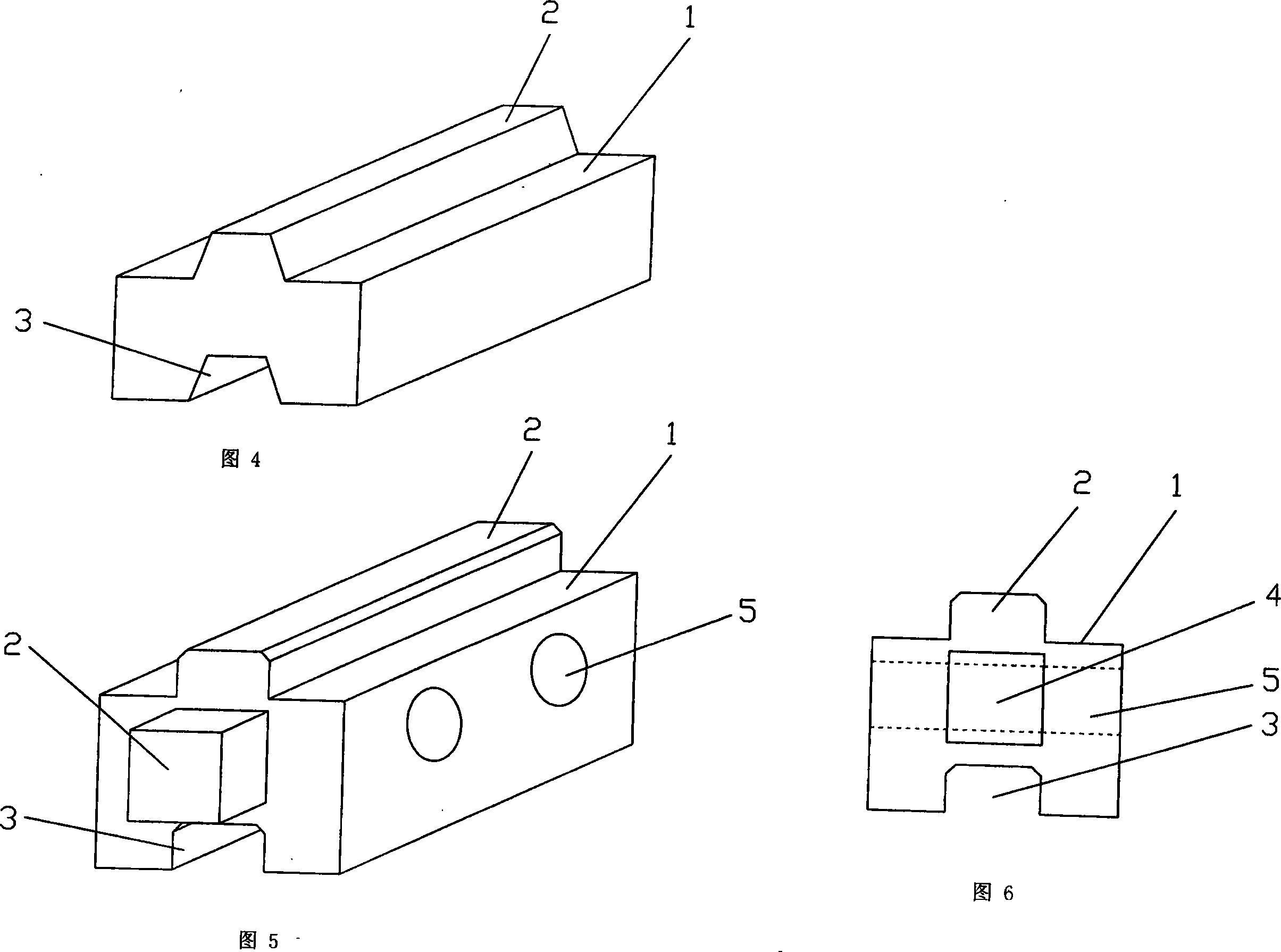

Embodiment 2

[0020] Embodiment 2: Referring to Fig. 5 and Fig. 6, a positioning embedded bricklaying, including unburned bricks, fired bricks, hollow bricks, solid bricks, semi-hollow bricks and stone bricks made by existing brick-making materials and existing production methods At least one "one" shape or "ten" shape or "well" shape or platform-shaped convex body 2 is provided on the adjacent two sides of the brick body 1, and the corresponding adjacent two sides of the brick body 1 are provided with At least one groove 3 of "one" shape or "ten" shape or "well" shape or table shape is provided with at least one hole 5 in the brick body 1. The hole 5 is a blind hole or a through hole. Or the cross-sectional shape of the through hole is square or polygonal or closed arc; at least one convex body 2 is provided on one side of the brick body 1, and a concave position 4 is provided at the other end of the brick body corresponding to the convex body 2.

[0021] In the present invention, two corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com