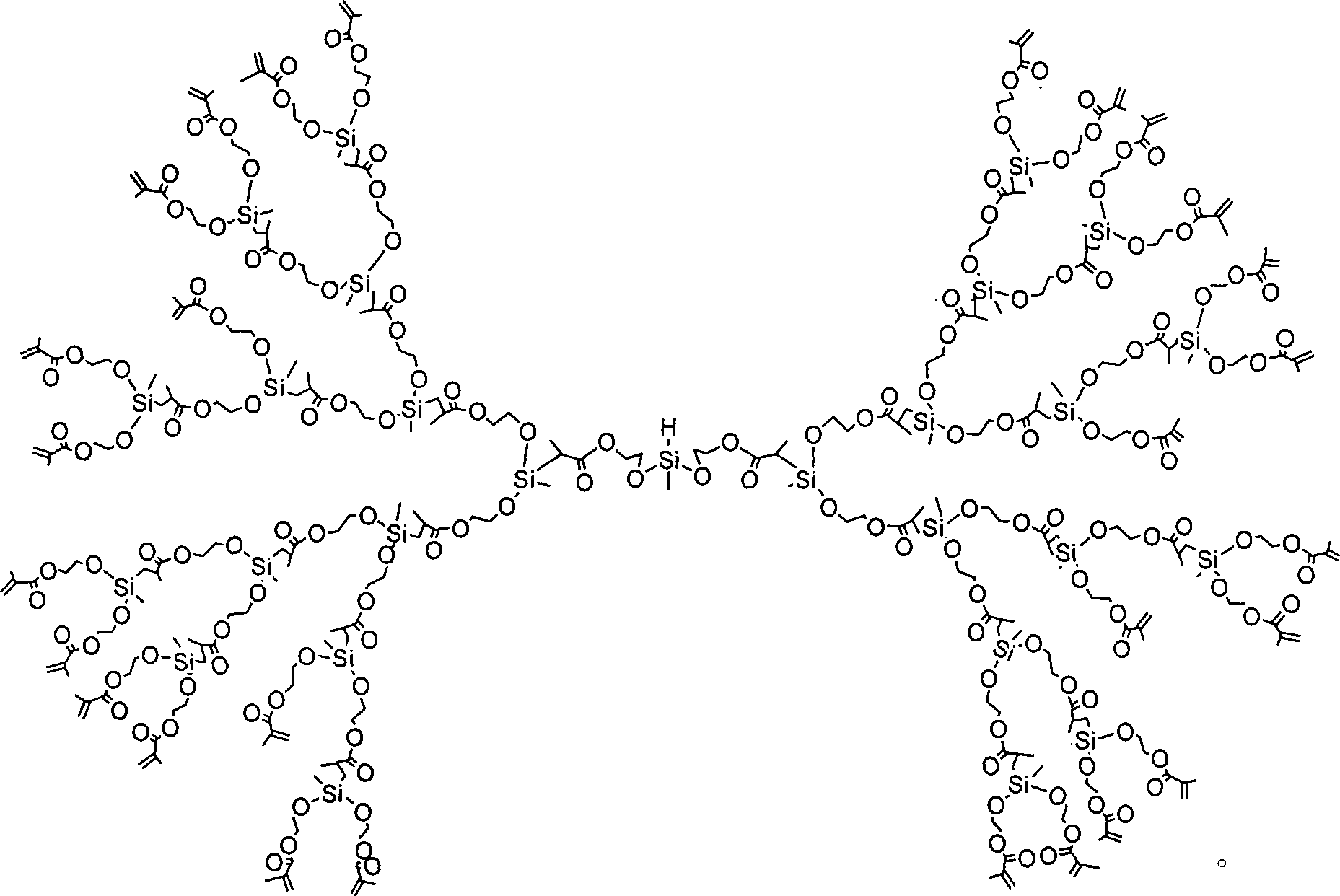

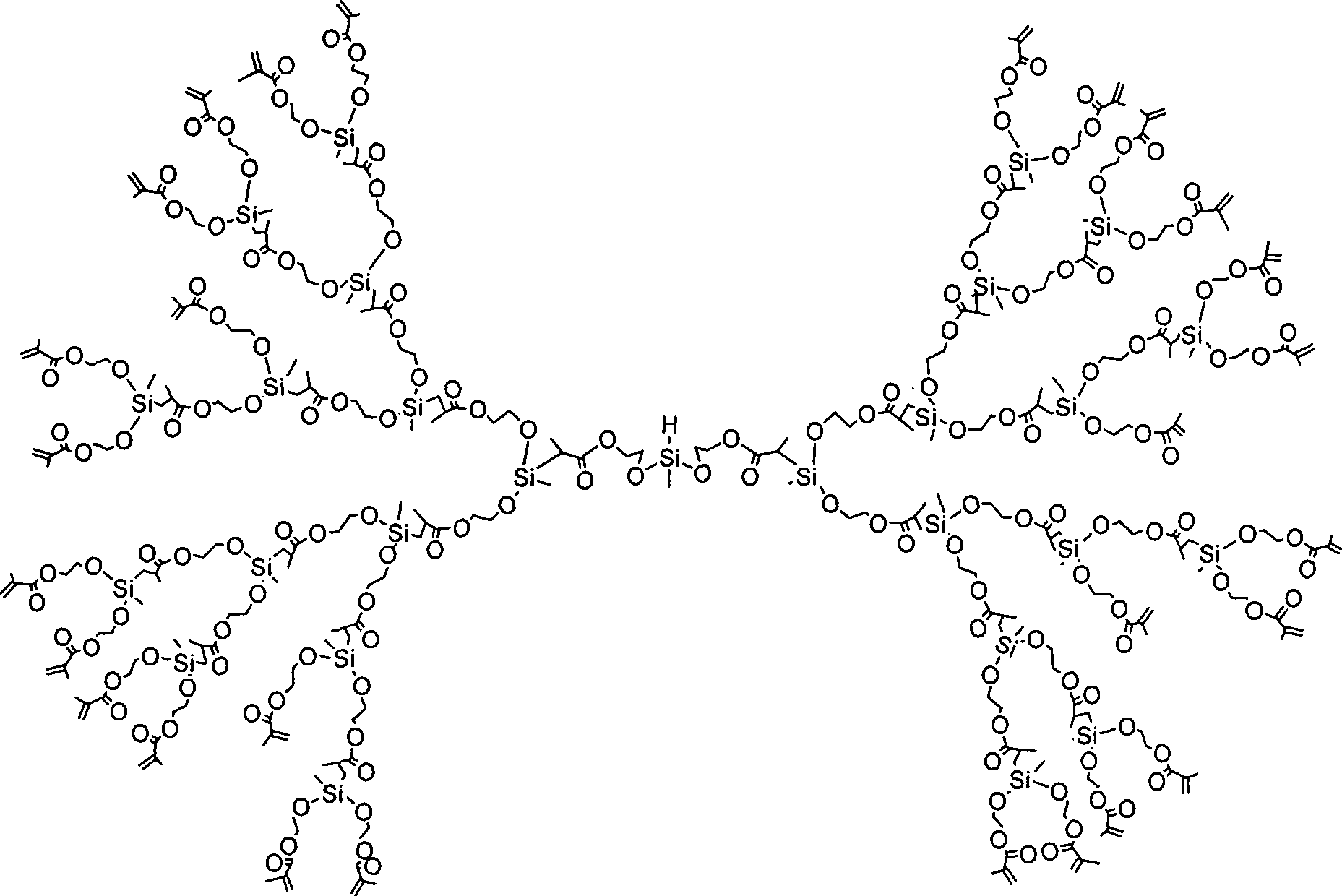

Superbranched poly-siloxane base photoresist

A polysiloxane-based and polysiloxane technology, applied in the field of photoresist, can solve the problems that the cured product cannot be converted into a functional device, and the viscosity of the photo-cured resin is high, so as to achieve excellent heat resistance and good heat resistance , the effect of high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 2g hyperbranched polysiloxane, 0.5g monofunctional monomer and 75mg photoinitiator Darocur 1173 were magnetically stirred at room temperature for 10min in the dark to obtain a photoresist.

Embodiment 2

[0016] 2g of hyperbranched polysiloxane, 1g of difunctional monomer and 100mg of photoinitiator IHT-PI 185 were magnetically stirred at room temperature for 10min in the dark to obtain a photoresist.

Embodiment 3

[0018] 2g of hyperbranched polysiloxane, 1g of monofunctional monomer, 50mg of photoinitiator IHT-PI 185 and 40mg of photoinitiator Darocur 1173 were magnetically stirred at room temperature for 10 minutes in the dark to obtain a photoresist.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com