Method for recovering tail gas of trichlorosilane production

A trichlorosilane and exhaust gas recovery technology, applied in the chemical industry, can solve the problems of high raw material consumption, uneconomical, unfavorable environmental protection, etc., and achieve the effect of strong permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

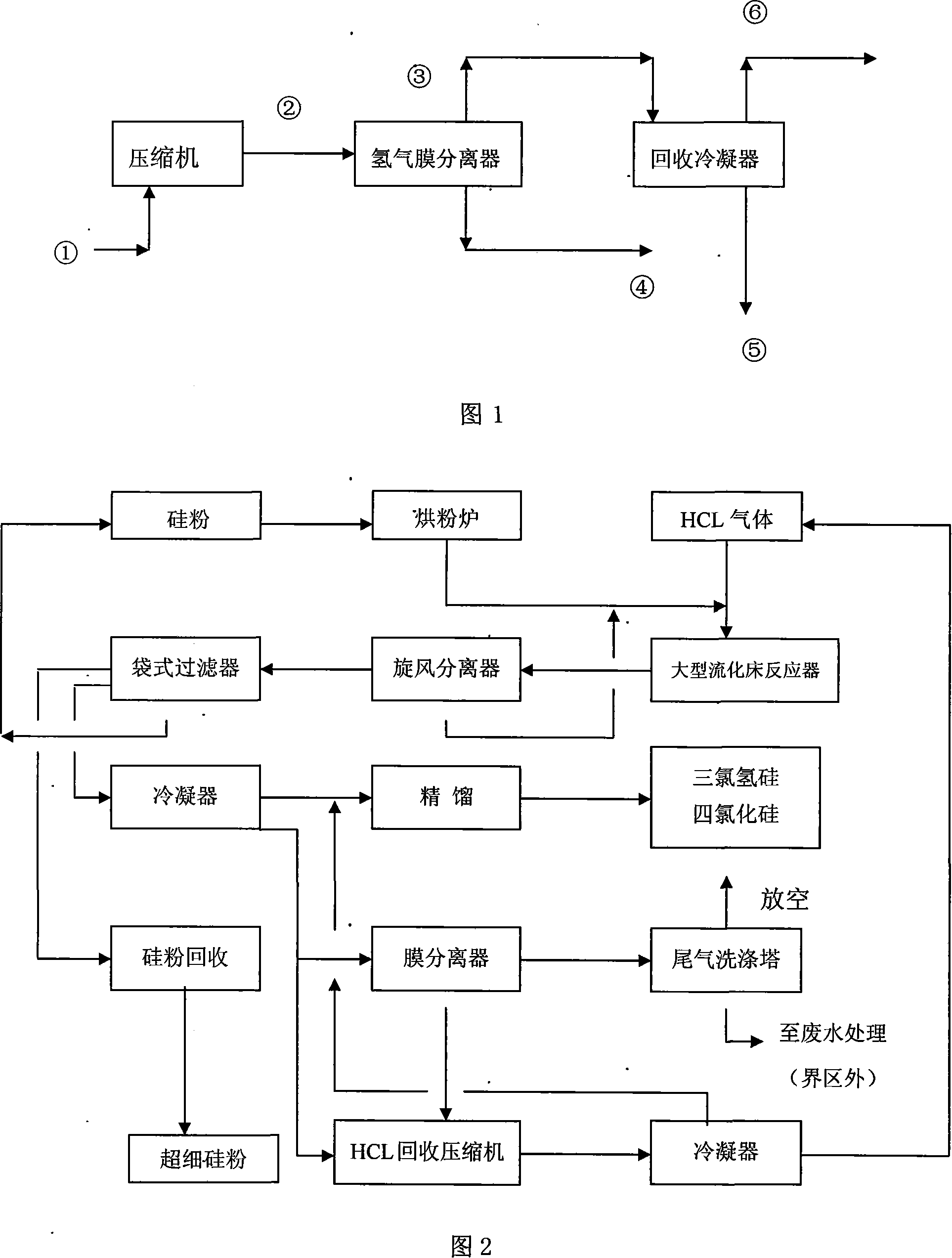

[0011] In the method of the present invention, the process of producing trichlorosilane in the existing fluidized bed reactor is subjected to dedusting, the synthetic gas adopts Freon direct evaporation and condensation process, and after cooling and condensing step by step, a part of non-condensable gas overflows, so , this part of the gas must be recovered, and the recovered hydrogen chloride can be reused as a raw material; the recovered trichlorosilane can be used as a product, and the recovered hydrogen can be used as a fuel or a raw material for the production of other products.

[0012] The applicant used the tail gas recovery method of trichlorosilane production of the present invention for the first time in the production process (Figure 1). This method utilizes the characteristics of strong hydrogen permeability, and after compression, hydrogen primary membrane separation, recompression, hydrogen secondary membrane Separation process, so that hydrogen can be easily pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com