Method and device for making consistence of anvil-roller and knife roller linear velocity

A technology of line speed and anvil roller, which is applied in the direction of transportation and packaging, packaging, rigid/semi-rigid container manufacturing, etc., and can solve the problems of irreconcilable purchase cost and use cost of die-cutting machines, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

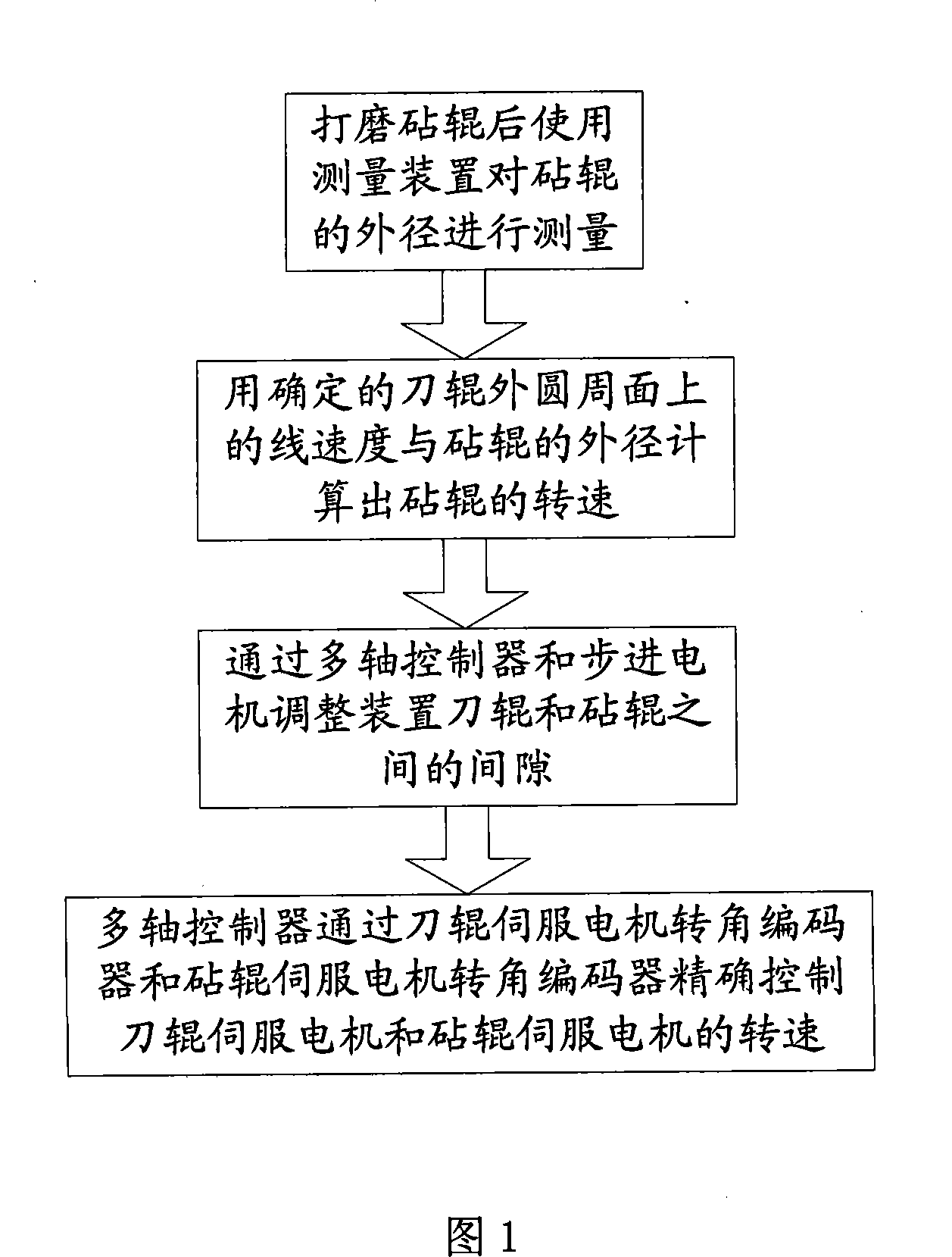

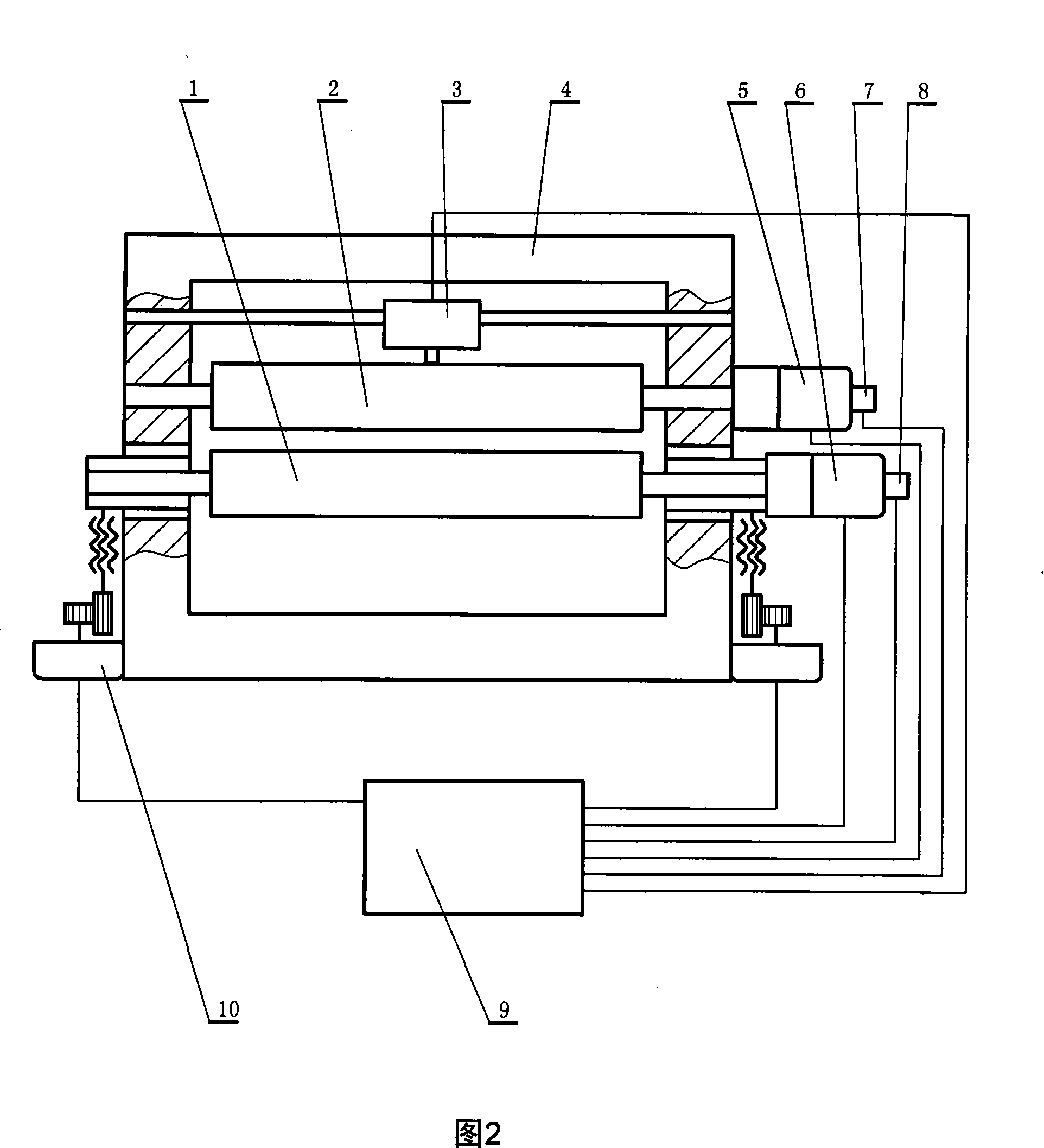

[0016] This embodiment is a method for making the anvil roll and knife roll linear speed consistent, and its process is shown in figure 1 The schematic block diagram. The devices used in this method are figure 2 As shown, it includes: knife roll 1, knife roll servo motor 6 driving the knife roll, knife roll servo motor angle encoder 8, anvil roll 2, anvil roll servo motor 5 driving the anvil roll, anvil roll servo motor angle encoder 7 3. The device for measuring the diameter of the anvil roll 3, the stepper motor adjustment device 10 for adjusting the gap between the anvil roll and the knife roll, the multi-axis controller 9, the steps of the method:

[0017] After grinding the anvil roll, use a measuring device to measure the outer diameter of the anvil roll. After grinding the anvil roll, it can be measured manually, using traditional measuring tools, such as micrometers, calipers or calipers, etc., as long as the accuracy meets the requirements. Input the measured data...

Embodiment 2

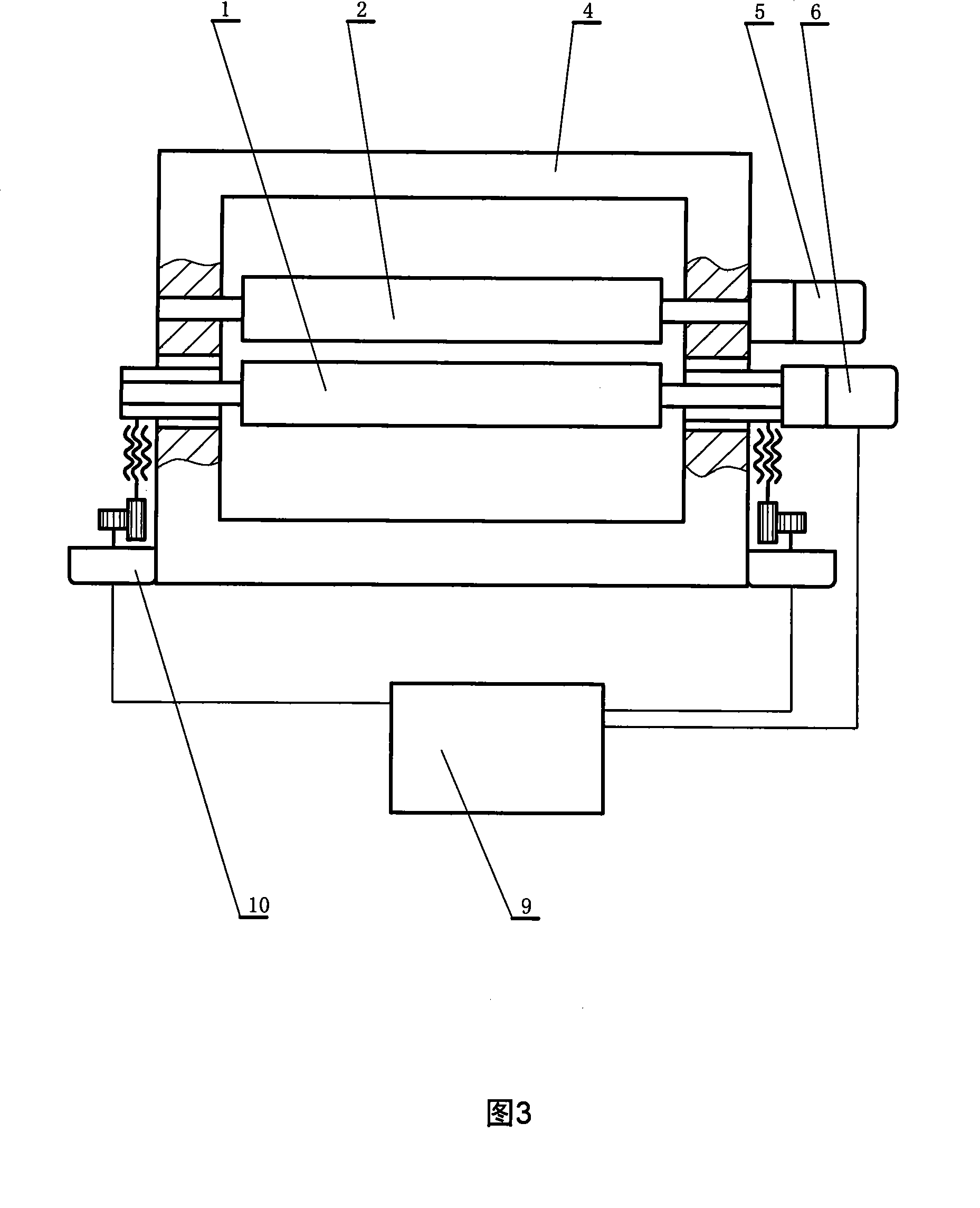

[0022] This embodiment is a device that makes the linear speeds of the anvil roll and the knife roll consistent, and is a device for realizing the method described in Embodiment 1. The device is as follows: image 3 shown.

[0023] The present embodiment includes a frame 4 as the whole machine skeleton.

[0024] The anvil roller 2 installed on the frame, the surface of the anvil roller is flexible rubber or plastic, has good wear resistance and elasticity, and the surface friction force is relatively large, which can drive the cardboard to move forward.

[0025] Below the anvil roll, the knife roll 1 is installed on the frame through a stepping motor adjustment device 10 for adjusting the gap between the knife roll and the anvil roll. The knife roller is the main device for the die-cutting machine to make creases on the cardboard. By cooperating with the anvil roller, on the one hand, it drives the cardboard to move forward, and at the same time, it uses the protruding ribs o...

Embodiment 3

[0030] This embodiment is an improvement of Embodiment 2, and the structure is as follows Figure 4shown. One end of the shaft end of the anvil roller servo motor 5 that is not connected to the speed reducer is connected with an anvil roller servo motor rotary angle encoder 7 for measuring the rotational angle of the anvil roller servo motor. One end of the shaft end of the cutter roller servo motor 6 that is not connected to the reducer is connected with a cutter roller servo motor rotation angle encoder 8 for measuring the rotation angle of the cutter roller servo motor. An anvil roller servo motor rotation angle encoder, a knife roller servo motor rotation angle encoder are electrically connected to the multi-axis controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com