Intermediate transfer chamber, substrate processing system, and exhaust method for the intermediate transfer chamber

An exhaust method and technology for conveying chambers, which are used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to slow down gas flow, prevent defects, and prevent particle adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

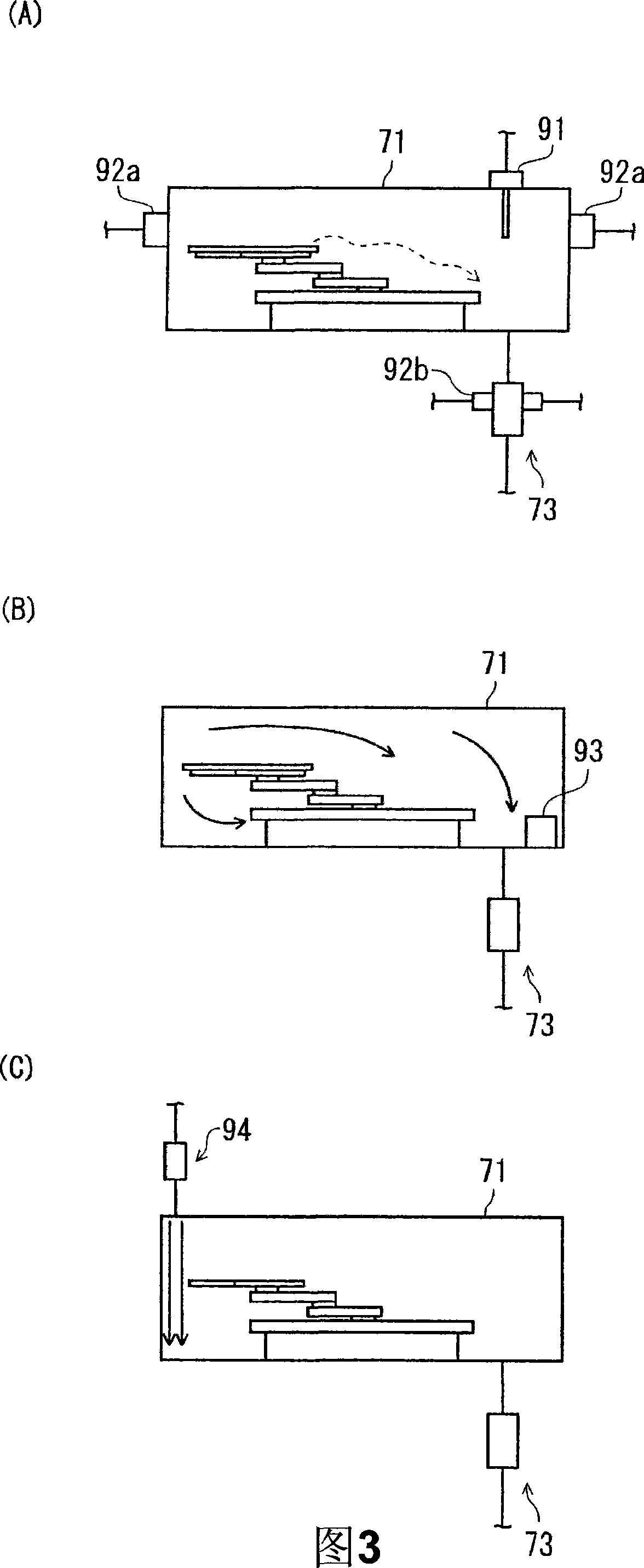

[0057] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0058] First, a substrate processing system according to an embodiment of the present invention will be described.

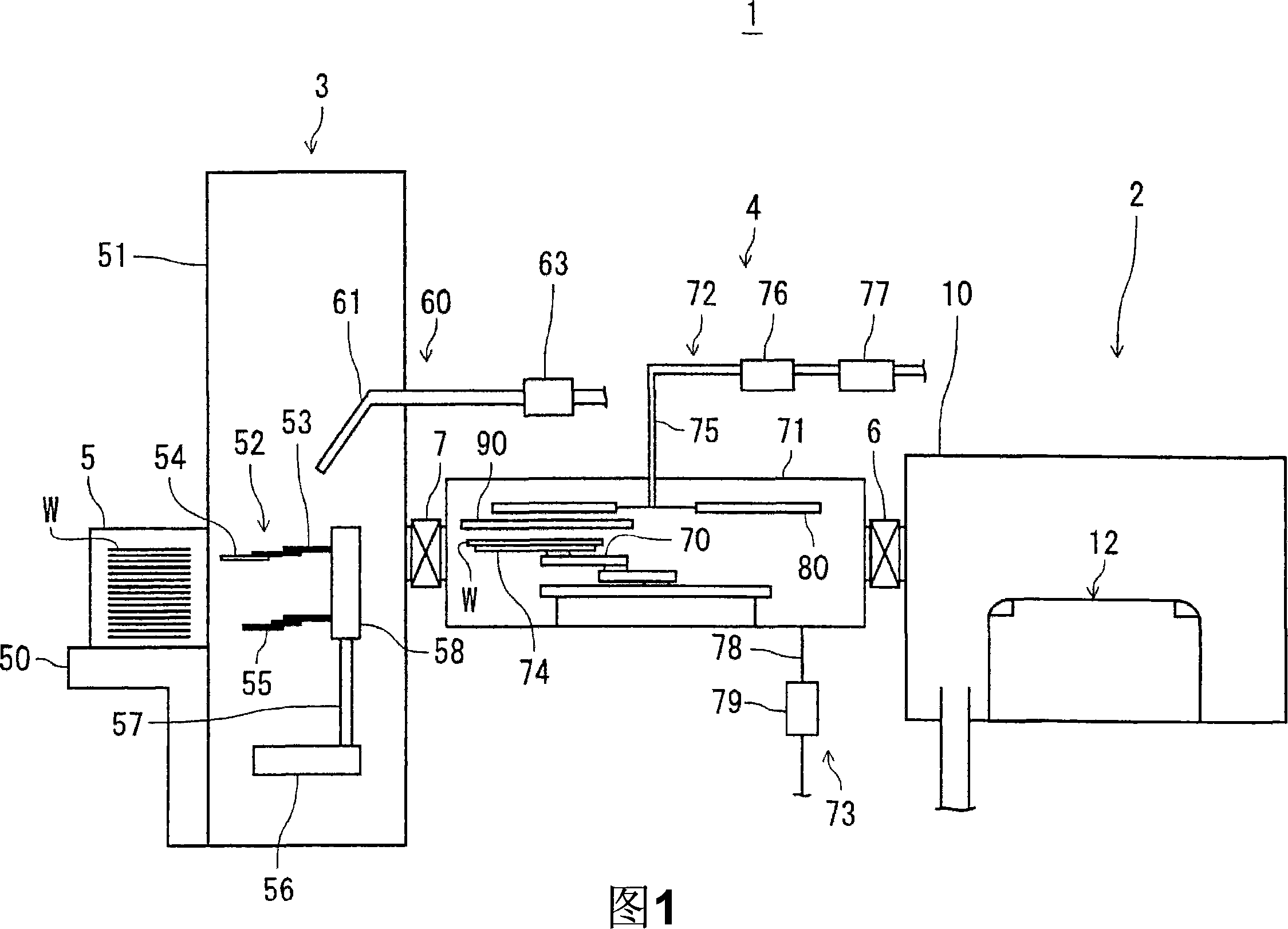

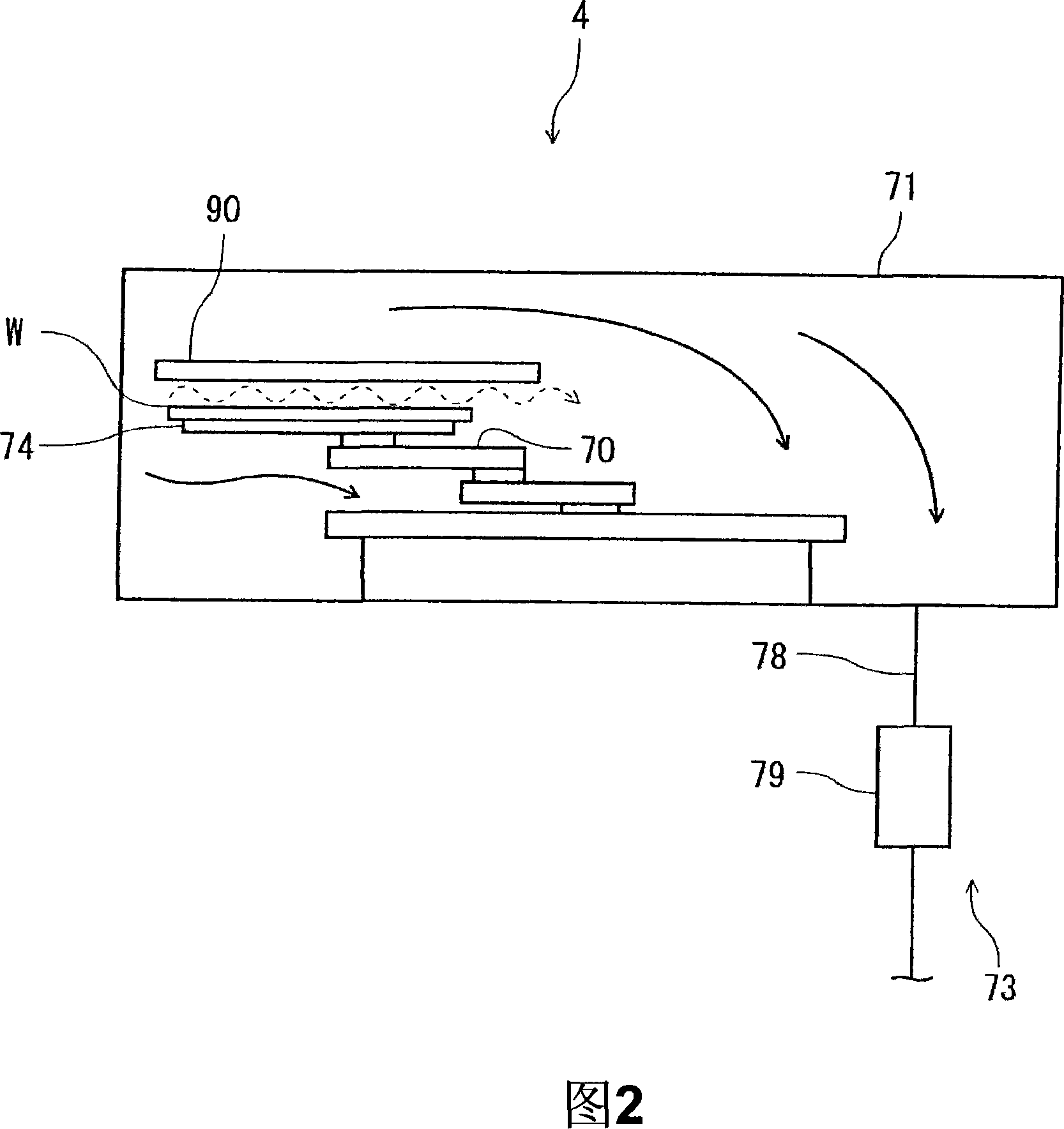

[0059] FIG. 1 is a cross-sectional view showing a schematic structure of a substrate processing system according to an embodiment of the present invention.

[0060] In FIG. 1 , a substrate processing system 1 includes a processing module for performing plasma processing such as RIE (Reactive Ion Etching) processing or ashing processing on a semiconductor wafer (hereinafter referred to as "wafer") W as a substrate. (Process Module) (hereinafter referred to as "P / M") 2; an atmospheric system for taking out the wafer W from the Front Opening Unified Pod (Front Opening Unified Pod: FOUP) 5 as a container for storing the wafer W The transport device 3; and the process of loading and unloading the wafer W from the atmospheric transport device 3 to the P / M2 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com