Method for producing poly-p-benzene dicarboxylic acid trimethylene glycol ester

A technology of polytrimethylene terephthalate and terephthalic acid, which is applied in the field of preparation of polytrimethylene terephthalate, and can solve the problems of lower thermal stability of polyester melt, yellowing of color, and inability to obtain light-colored products, etc. problem, to achieve the effect of good thermal stability and good color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

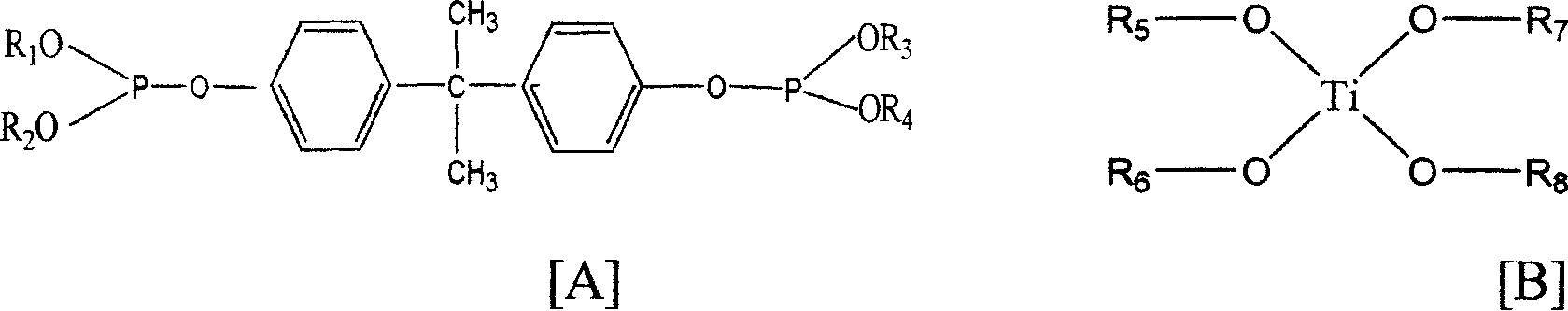

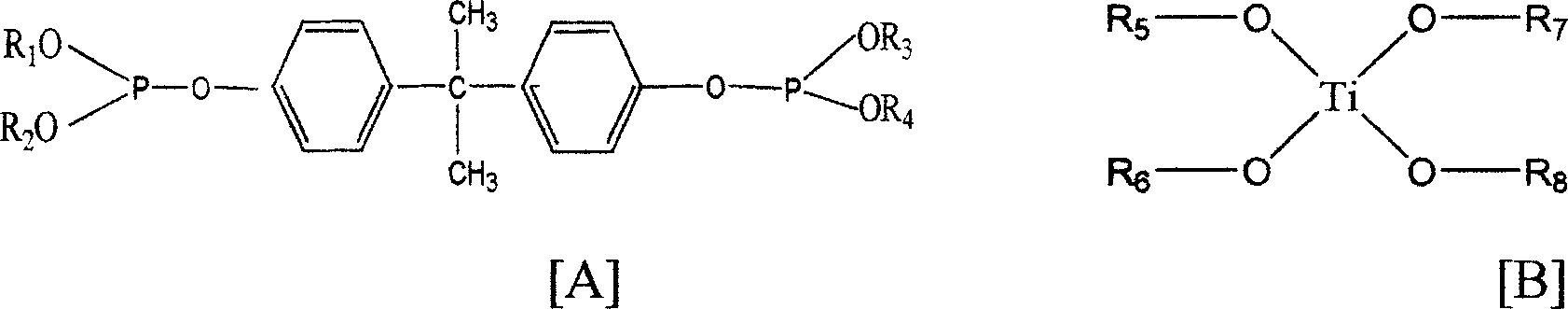

[0020] A method for producing poly(trimethylene terephthalate), comprising esterification of terephthalic acid and 1,3-propylene glycol, and polycondensation of the esterification product, wherein the esterification catalyst used is tetrabutyl titanate ester (or tetraisopropyl titanate, tetraethyl titanate, titanium sulfate hydrolyzate, organic tin catalyst), the titanium compound of the following structural formula (B) is used as a catalyst in the polycondensation reaction, and the phosphorus compound of the following structural formula (A) is used. Compounds as stabilizers:

[0021]

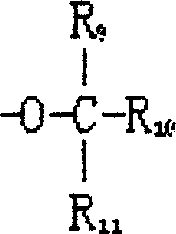

[0022] Among them, R1~R4 in the phosphorus-containing compound [A] is an alkyl, cycloalkyl or aromatic hydrocarbon group with 4 to 25 carbons; for example, R1~R4 can be 3-methyl-5-ethyloctane, 2, 5-Dimethyl-3,4-diethylhexane, lauryl, stearyl, 2,3,7-trimethyl-5-ethyloctane, 2,4-dibutylphenyl, Octylphenyl, phenylnonyl, phenylbisphenol A, phenylisodecyl, etc.

[0023] R5-R8 in the titanium co...

Embodiment 2

[0034] Relative to the final polyester product amount, the addition amount of titanium element in the polycondensation reaction catalyst is 40ppm, and the addition amount of phosphorus element in the stabilizer phosphorus compound is 40ppm. All the other are with embodiment 1.

Embodiment 3

[0036] A toner cobalt compound, cobalt acetate, is also added to the polycondensation reaction.

[0037] Relative to the final polyester product amount, the addition amount of titanium element in the polycondensation reaction catalyst is 60ppm, the addition amount of phosphorus element in the stabilizer phosphorus compound is 40ppm, the addition amount of cobalt element in the toner cobalt compound is 30ppm, and the rest are implemented in the same way example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com