Hole-digging and temperature-reducing drilling tool for outburst coal seam and drilling method thereof

A technology for protruding coal seams and drilling tools. It is applied in the field of drilling and cooling drilling tools. It can solve problems such as drill sticking, excessive heat generation by friction of drill pipes, and large equipment, so as to improve the effect and prevent gas burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

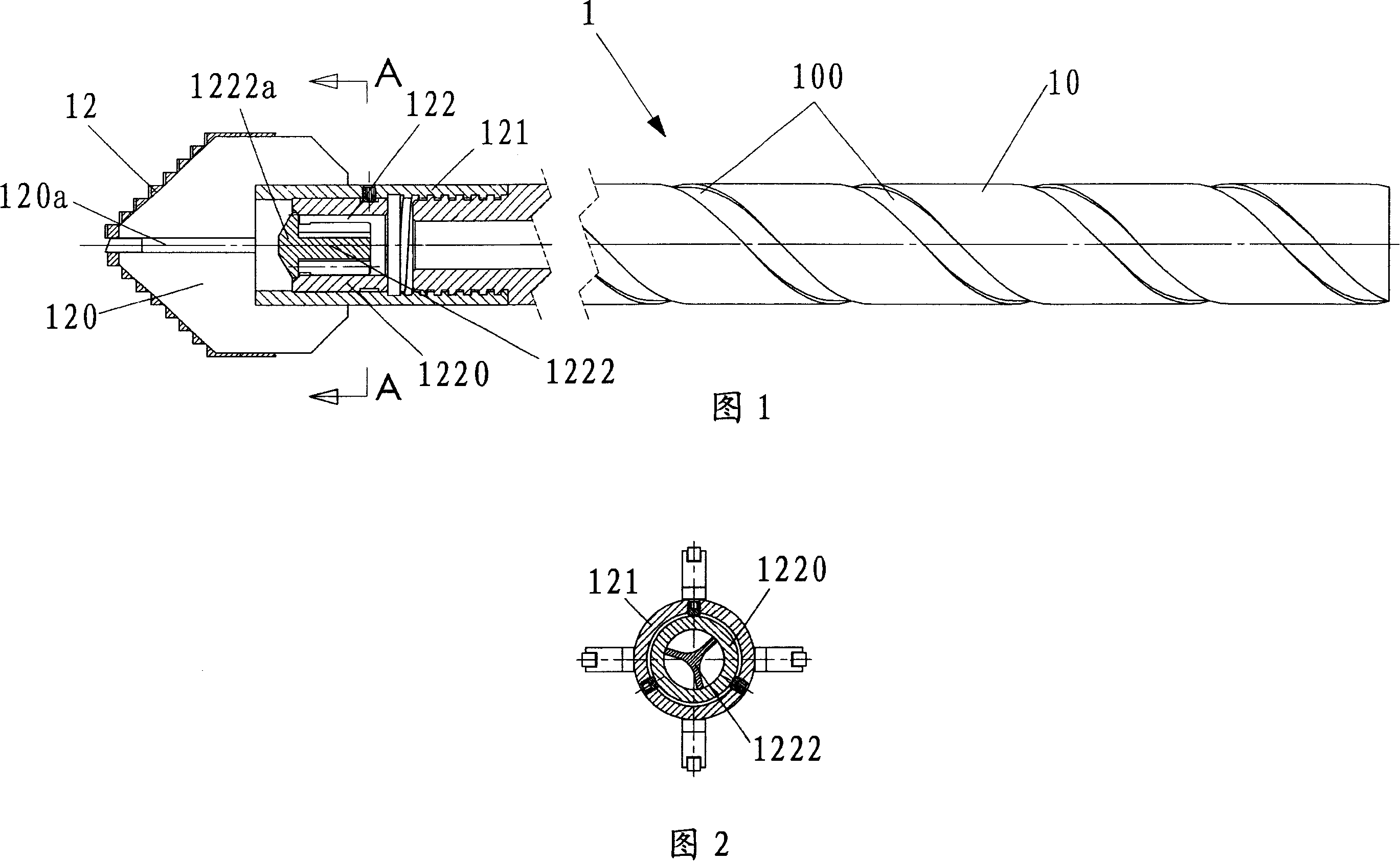

[0019] Please refer to FIG. 1 , the outburst coal seam grilling and cooling drilling tool 1 of the present invention includes a grilling and cooling drill rod 10 and an anti-blocking drill bit assembly 12 arranged at one end of the grilling and cooling drill rod 10 .

[0020] Please refer to FIG. 1 and FIG. 2 in conjunction, the drill pipe 10 for drilling and cooling has an inner hole for passing high-pressure airflow, and a spiral conveying groove 100 is provided on its outer surface for conveying coal cinders to the outside. There are two methods for forming the spiral conveying trough 100: one is to cut the spiral conveying trough 100 on the outer circle of the drilling rod 10; the other is to weld the spiral steel belt on the outer circle of the drilling rod 10 to form a spiral conveying groove 100. The spiral conveying trough 100 on the grilled cooling drill pipe 10 can be single or multiple, and its parameters such as number, width, depth and helix angle can be adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com