Built-in coupling optical ring cavity device

A technology of annular cavity and coupling light, applied in the direction of coupling of optical waveguide, etc., can solve the problems of complex process, and achieve the effect of simplifying film structure, improving coupling efficiency and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further illustrate the present invention below in conjunction with accompanying drawing.

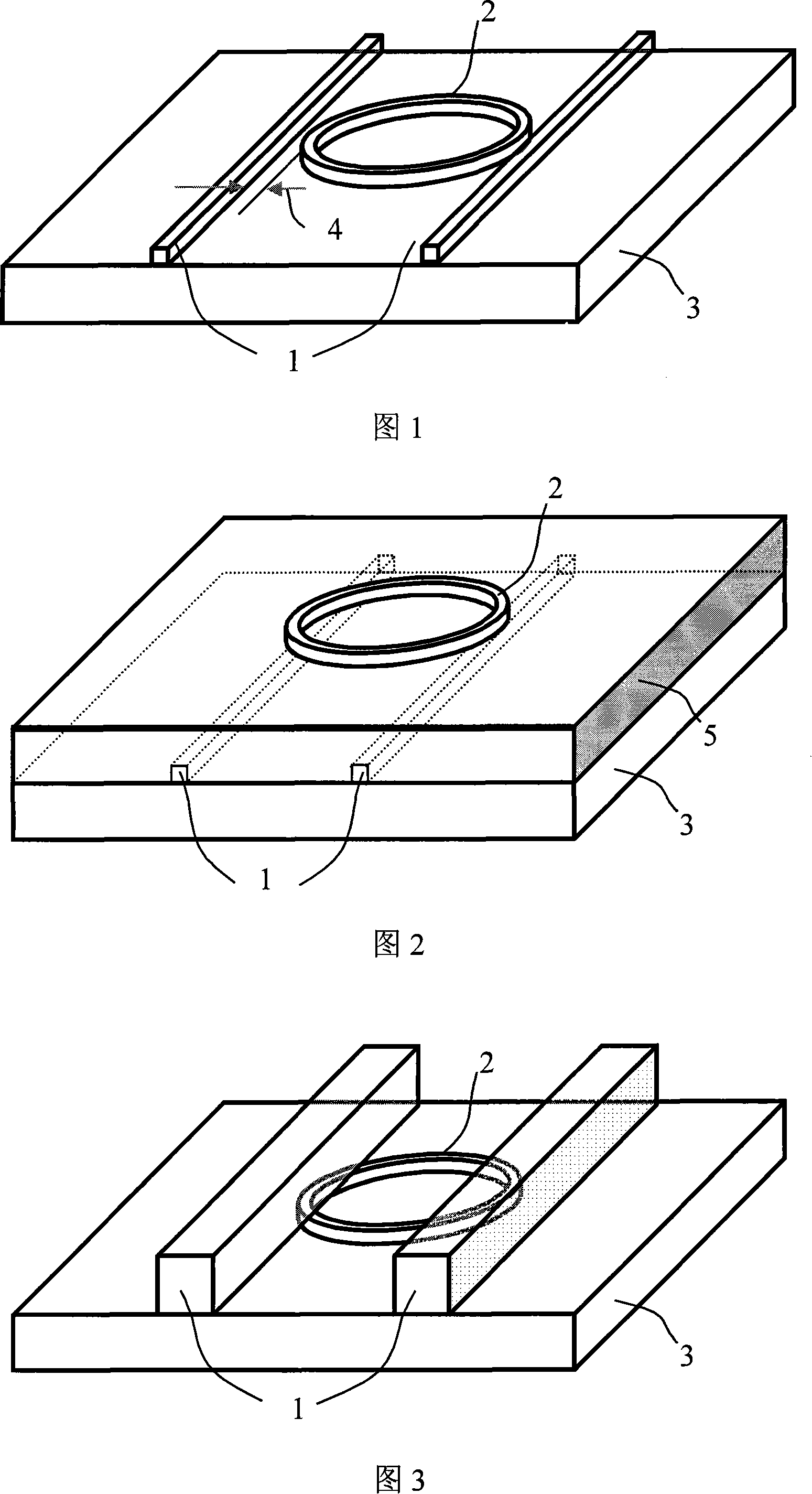

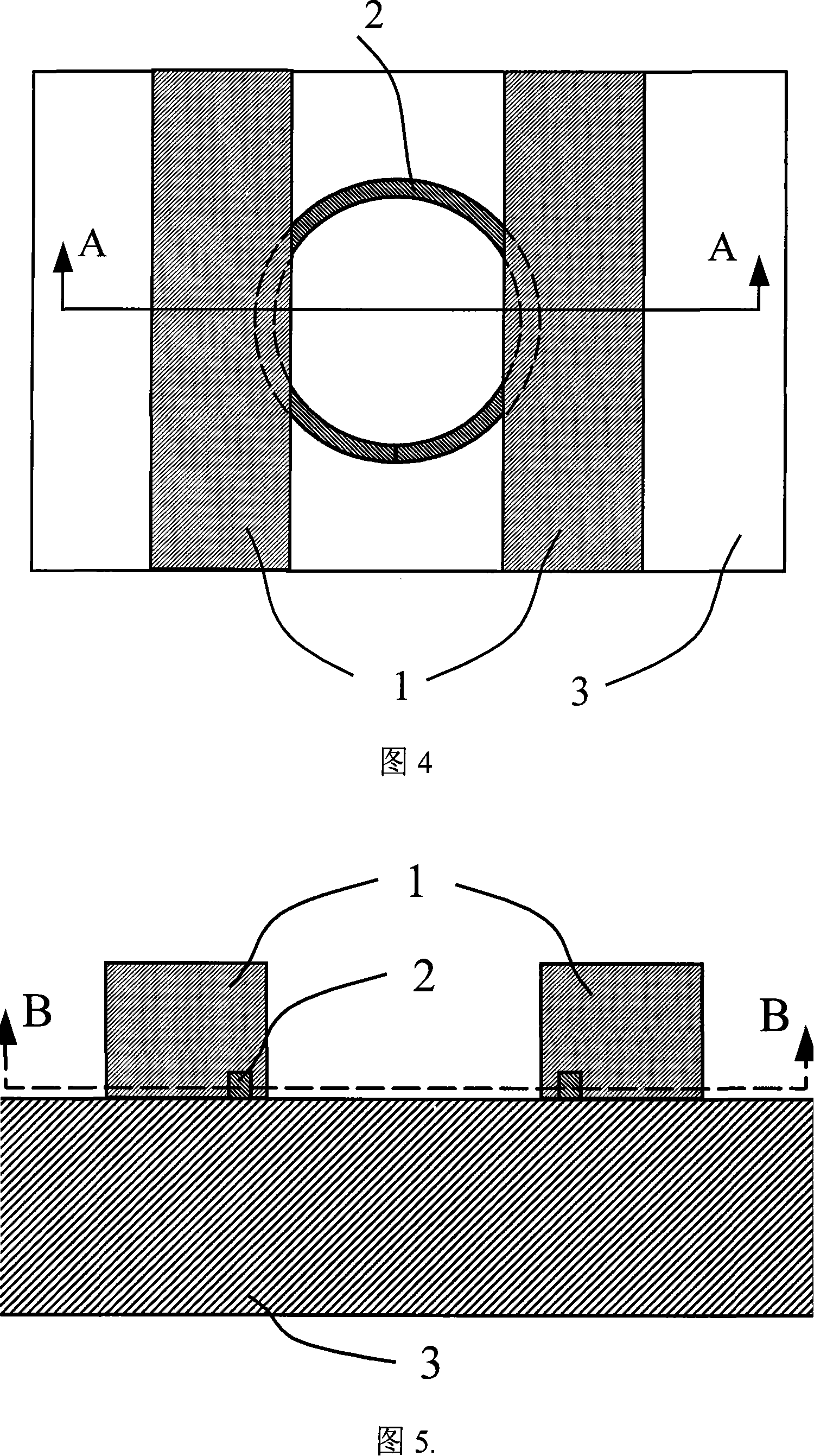

[0018] Referring to FIGS. 3 to 6 , the embedded coupling optical ring cavity device of the present invention includes a coupling optical waveguide 1 , a ring cavity optical waveguide 2 and a substrate isolation layer 3 . The coupling optical waveguide 1 and the ring cavity optical waveguide 2 share the substrate isolation layer 3 , and the ring cavity optical waveguide 2 is embedded in the coupling optical waveguide 1 in the coupling region between the ring cavity optical waveguide 2 and the coupling optical waveguide 1 .

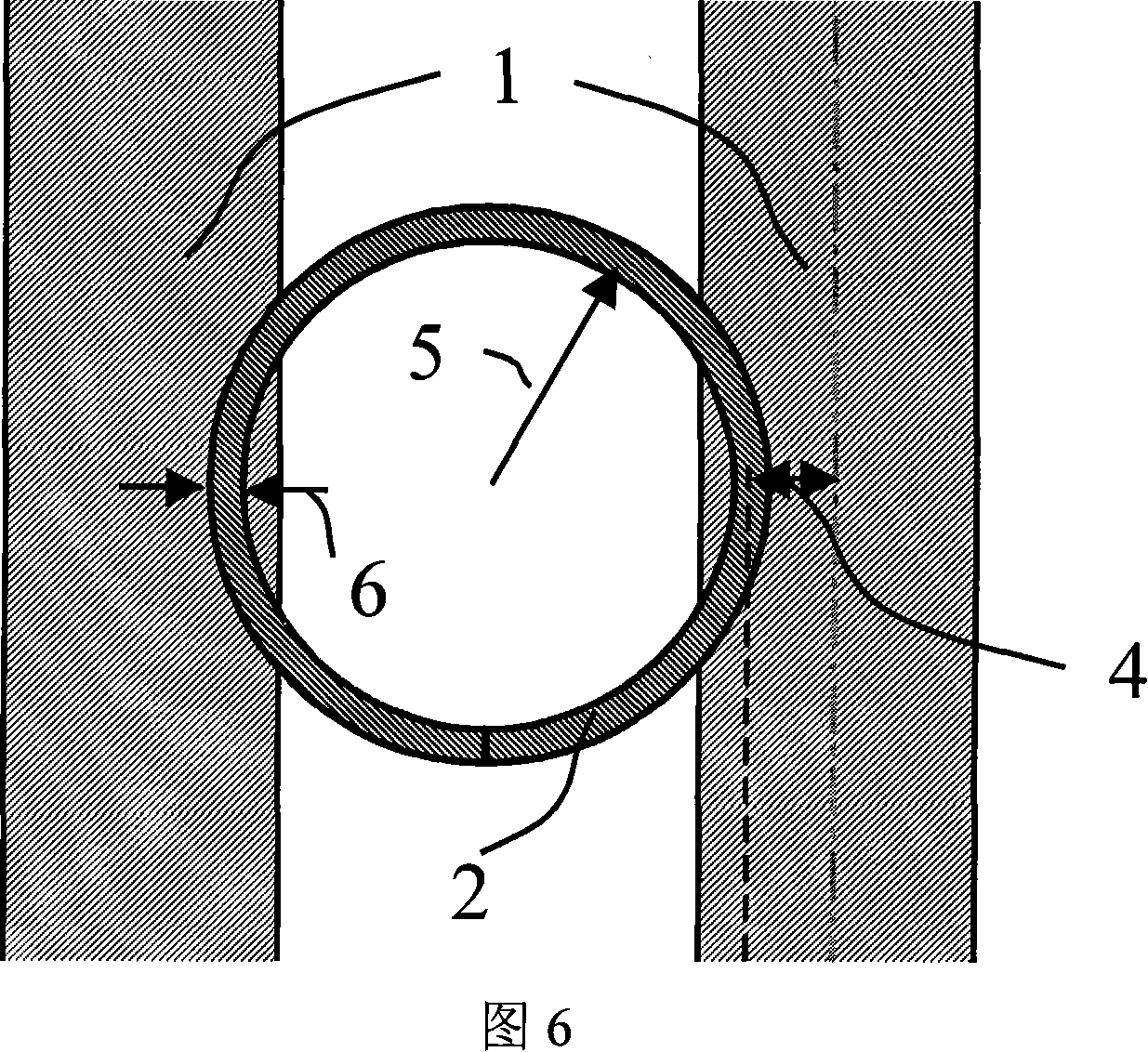

[0019] By changing the center distance 4 between the coupling optical waveguide 1 and the ring cavity optical waveguide 2 (see FIG. 6 ), different coupling coefficients between the ring cavity optical waveguide 2 and the coupling optical waveguide 1 can be obtained.

[0020] By changing the bending radius 5 of the ring cavity optical waveguide 2 (see FIG. 6 ), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com