Temperature control device of etching equipment and its method for controlling wafer temperature

A technology of etching equipment and temperature control device, which is applied in the field of temperature control system, can solve the problems that the edge of the wafer cannot be cooled, the gas volume cannot be controlled and measured, and the pressure of the back cooling gas is affected, so as to change the heat dissipation effect and structure. Simple, temperature-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

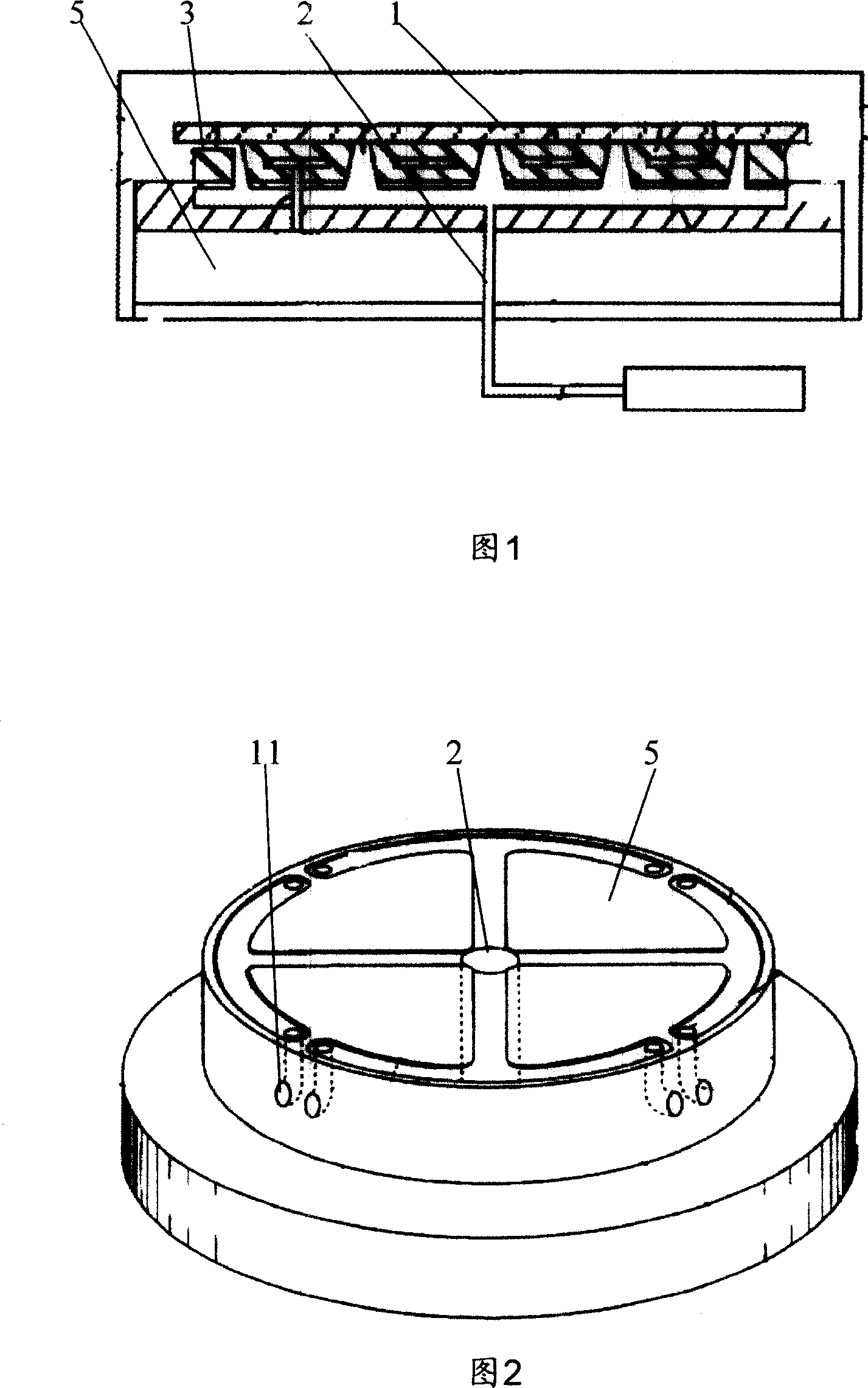

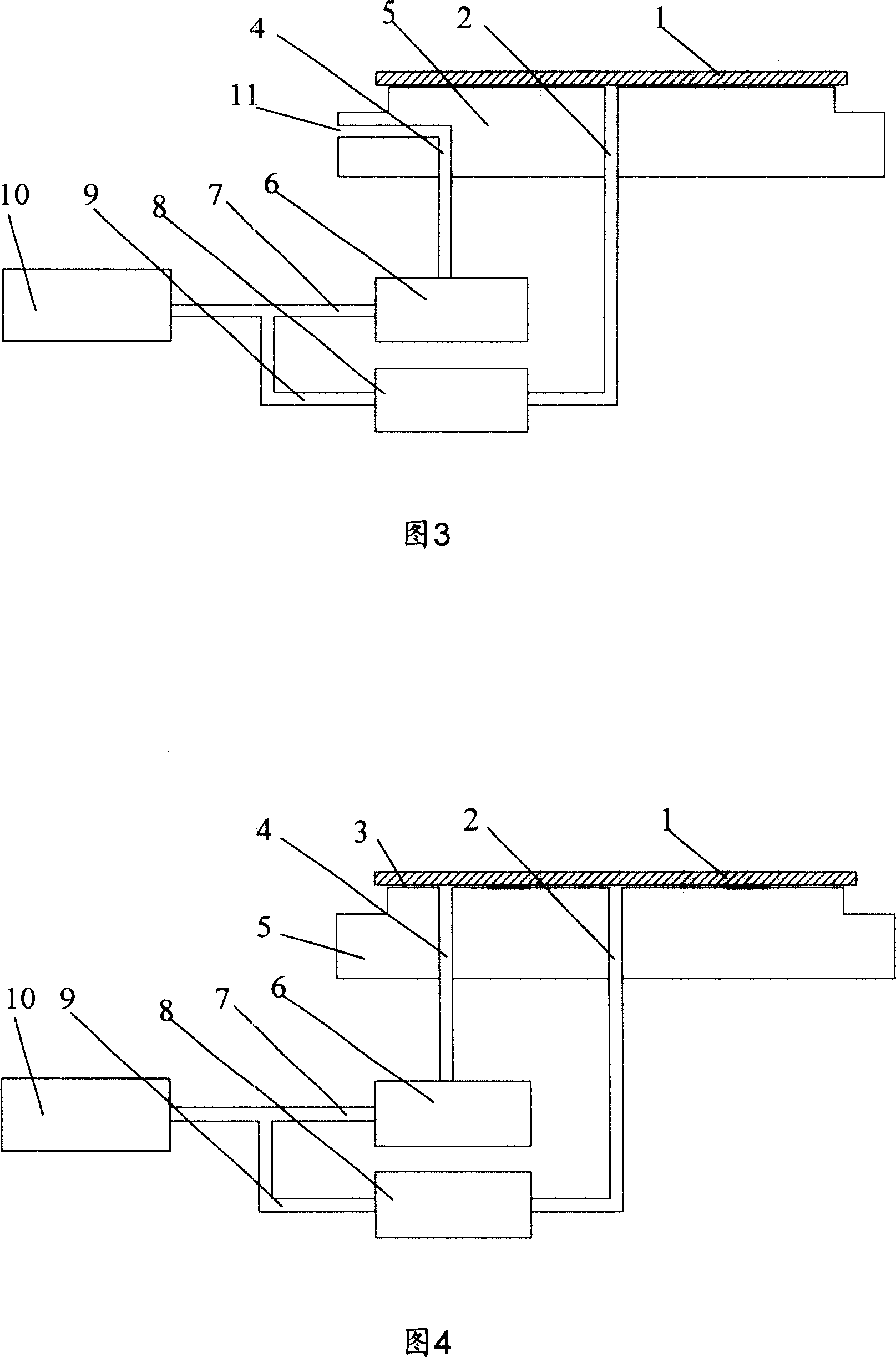

[0041] For this reason, preferred specific implementation mode 1 that the present invention adopts, as shown in Figure 3:

[0042] One or more back cooling gas leakage holes 11 are provided on the edge of the electrostatic chuck 5 , the back cooling gas leakage holes 11 communicate with the edge back cooling gas channel 4 , and the back cooling gas can leak along the edge back cooling gas channel 4 partly.

[0043] The first preferred specific implementation mode adopted by the present invention, as shown in Figure 4:

[0044] At the edge of the electrostatic chuck 5 , specifically at the edge of the edge back cooling gas channel 4 , the part of the contact surface 3 that is in contact with the wafer 1 is slightly rough, and the back cooling gas can leak along the rough surface 3 .

[0045]The central back-cooled gas channel 2 is connected to the central gas path 9 , and the edge back-cooled gas channel 4 is connected to the edge gas path 7 . A pressure controller 8 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com