Organic wastewater treatment method and apparatus

A technology for organic wastewater and water treatment, applied in the field of anaerobic treatment, can solve the problems of reduced concentration of granular sludge, difficulty in continuous treatment, low COD removal rate, etc., and achieve the effect of promoting contact reaction and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

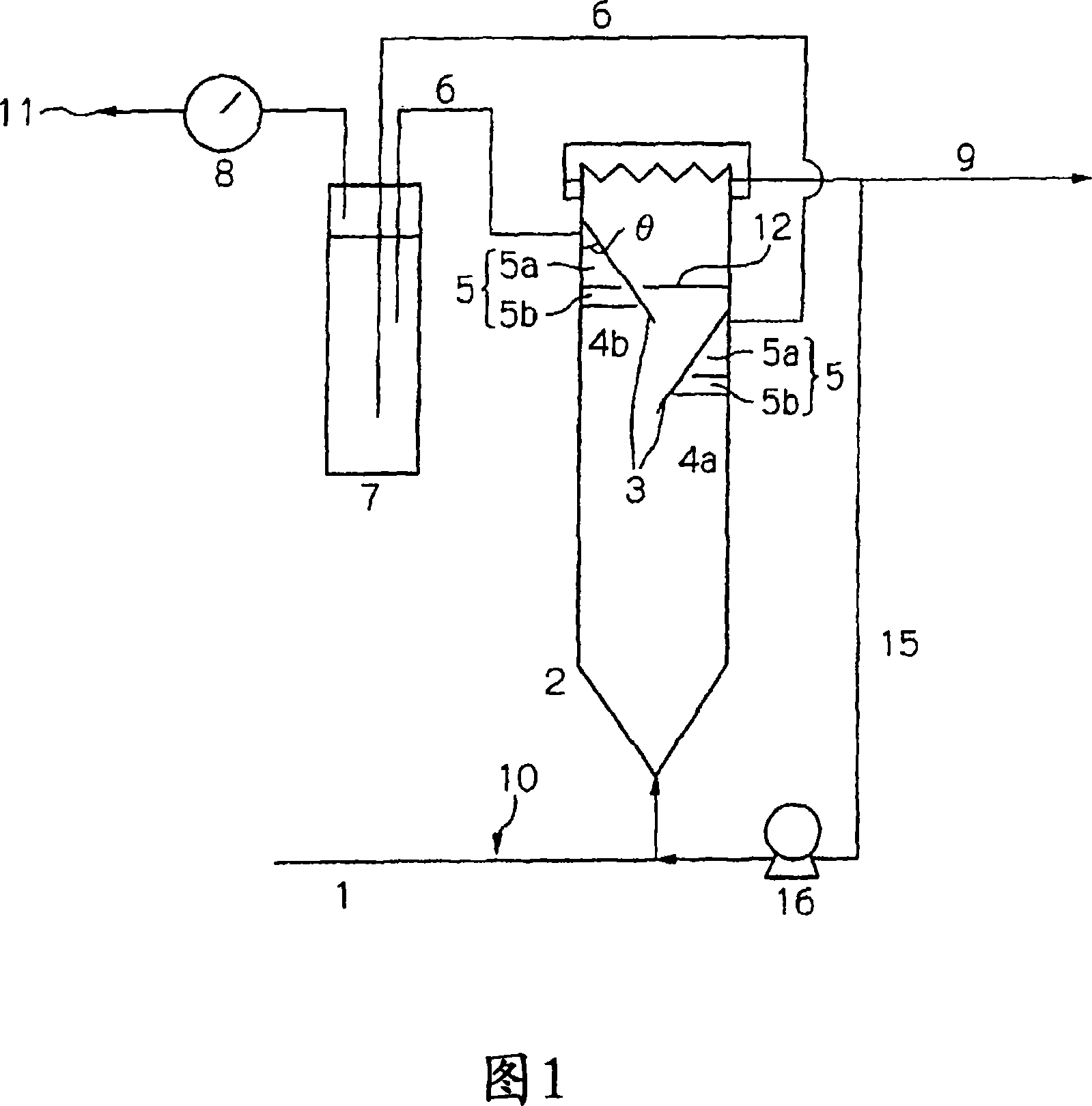

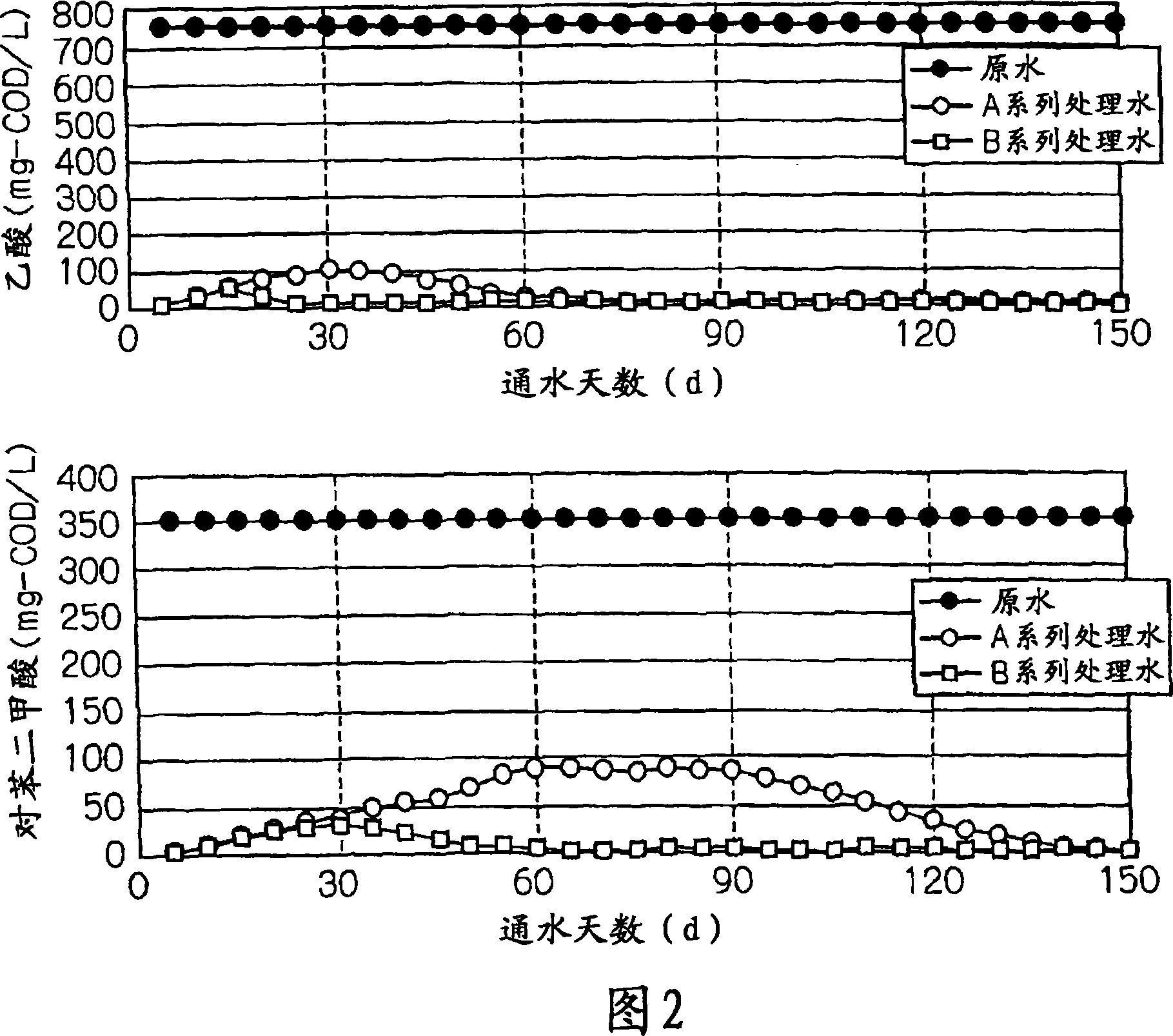

[0054] In the experiment, 2 series (A series, B series) of the upflow type anaerobic reactor filled with activated carbon as shown in FIG. 1 were used.

[0055] The devices of series A and series B have the same structure, and two inclined baffles are installed so that the angle between the side wall of the device and the baffle 3 is 30 degrees, and defoaming agent is added to the raw water. The capacity of the liquid layer part is 100 liters. The water temperature in the reactor was controlled at a temperature of 35°C. These two reactors were filled with 60 liters of granular activated carbon having an effective particle diameter of 0.3 mm and an equalization coefficient of 1.5, and 10 liters of UASB particles (MLSS concentration 5%) for treating beverage wastewater as seed sludge.

[0056] In raw water, use sodium acetate (based on COD cr Conversion, 750mg / L) and terephthalic acid (based on COD cr In conversion, it is 350 mg / liter) mixed, and inorganic nutrient salts (nit...

Embodiment 2

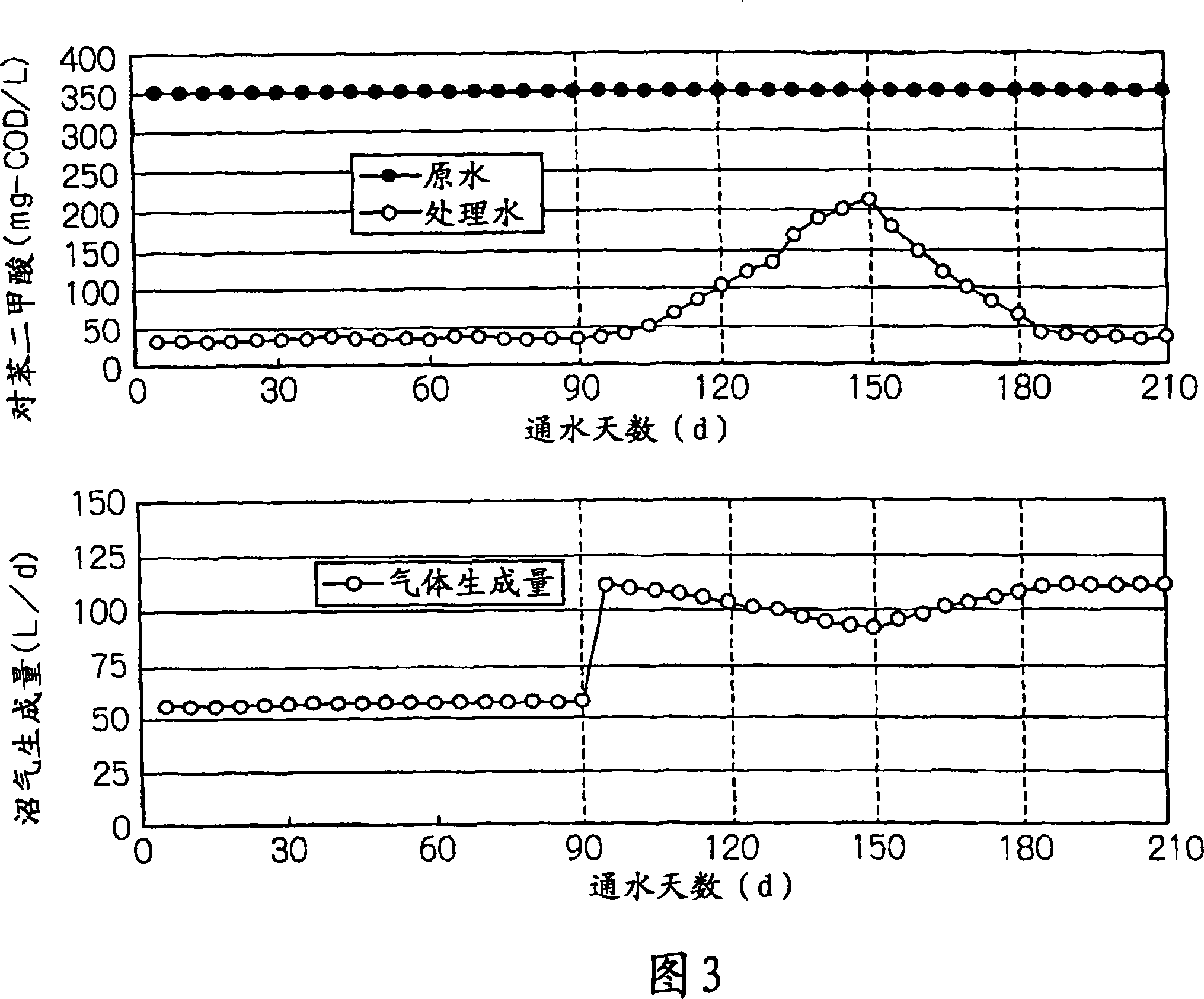

[0063] Using the B series used in Example 1 above, the experiment was started again using the raw water of Example 1. The experimental results are shown in Figure 3. By day 90, the COD load was 3kg / m 3 / day, the raw water volume is 150 liters / day, and the circulating fluid volume is 300 liters / day. The amount of biogas generated is 55 liters / day, and the COD concentration of the treated water is 35 mg / liter. After the 91st day, make the COD load 6kg / m 3 / day, the circulating liquid volume is still 300 liters / day, only the raw water volume is increased to 300 liters / day. Until the 100th day, with the increase of the load, the COD concentration of the treated water was 35mg / L, and there was almost no change. Although the gas generation amount of the treated water increased, but after that, it was found that the concentration of terephthalic acid hindered, and at the 150th day day, the amount of biogas production is reduced to 90 liters / day. Calculated from the amo...

Embodiment 3

[0065] The upflow anaerobic reactor filled with activated carbon shown in Fig. 1 was used in the experiment. The internal structure of the reactor, the filled activated carbon and the kind of sludge are the same as in Example 1. As raw water, glycol wastewater from a chemical factory is used. COD of the raw water cr The concentration is about 10,000mg / liter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com