Elevator control apparatus

A technology for elevator control and equipment, applied in elevators, transportation and packaging, etc., can solve the problems of consuming regenerative energy, increasing the size of elevator control equipment, increasing the manufacturing cost of elevator control equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

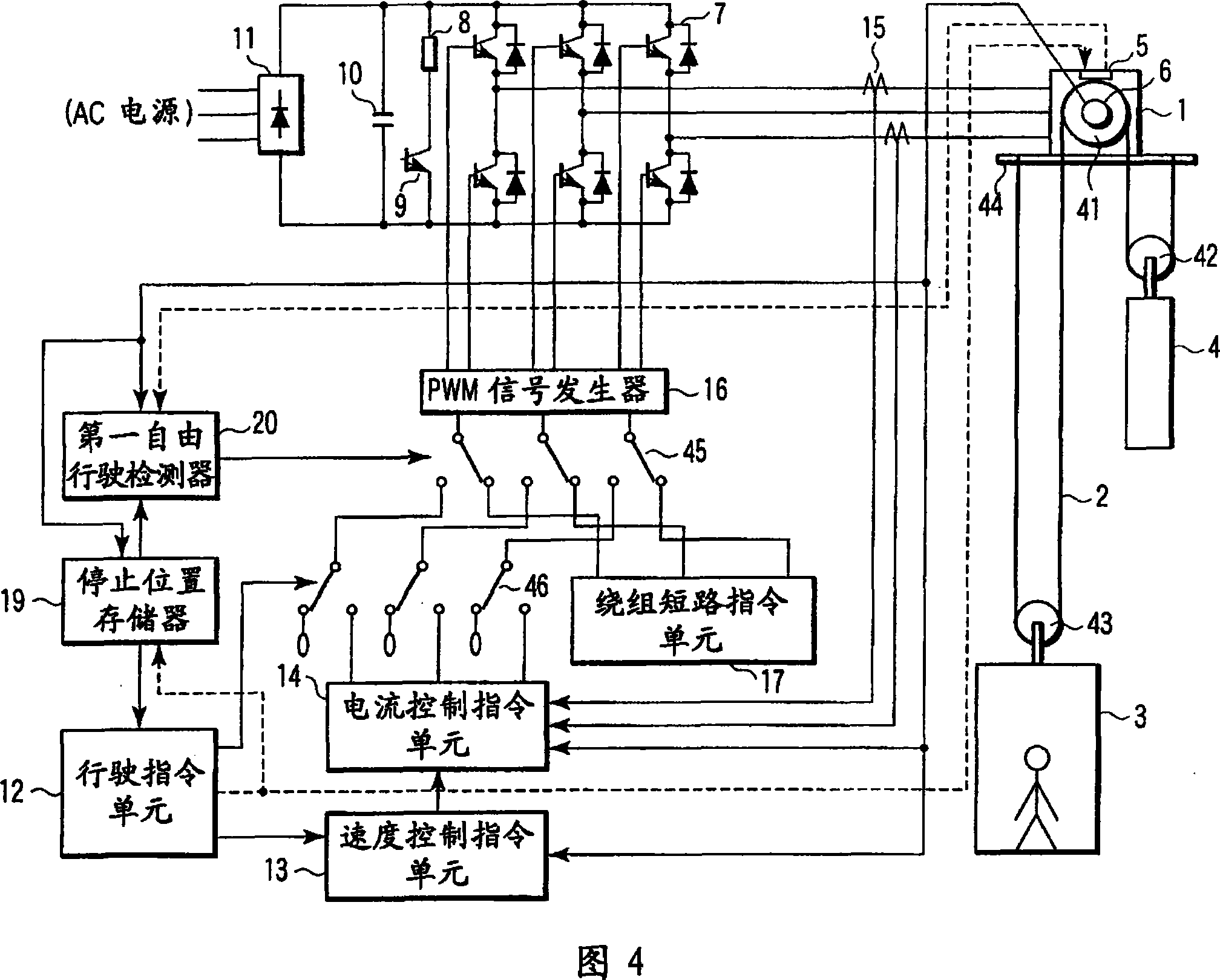

[0022] A first embodiment of the present invention will be explained.

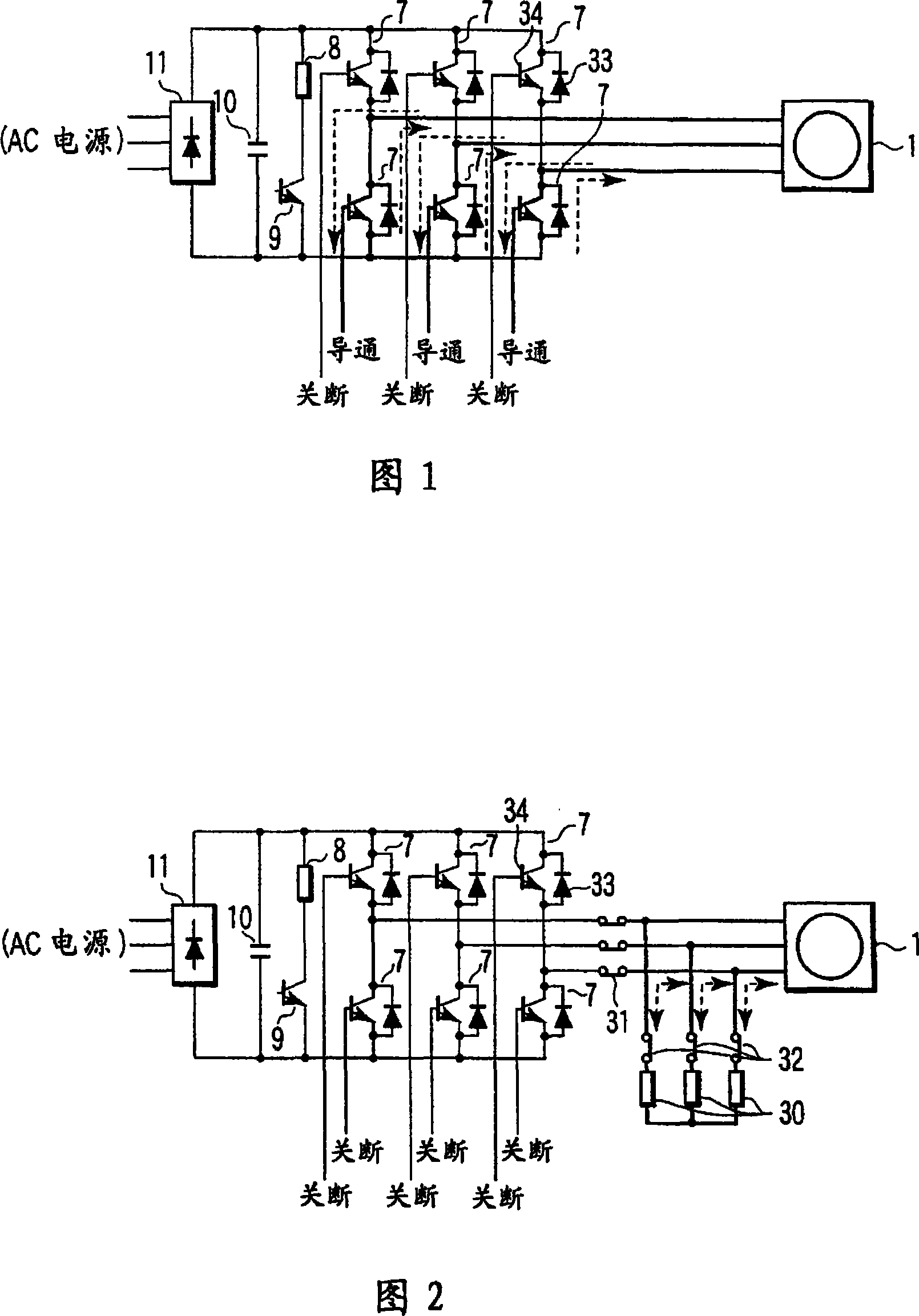

[0023] Dynamic braking will be explained first. Fig. 1 shows a configuration example of dynamic braking of an elevator control apparatus according to a first embodiment of the present invention.

[0024] In the dynamic braking shown in FIG. 1 , the three-phase alternating current supplied from the AC power source is full-wave rectified by the rectifier circuit 11 into direct current. Ripples in the rectified direct current are absorbed by the smoothing capacitor 10, and the direct current is supplied to the inverter circuit. At both ends of the smoothing capacitor 10, a series circuit composed of a damping resistor 8 and a damping resistor energization element 9 is provided.

[0025] In the inverter circuit, six parallel circuits 7 composed of diodes 33 and switching elements 34 are connected in bridge form. By energizing and interrupting each switching element 34 of the inverter circuit with a pulse wi...

Embodiment 2

[0053] A second embodiment of the present invention will be explained. Among the components of the elevator control apparatus according to the following embodiments, the explanation of the same components as those shown in FIG. 1 is omitted. In the operation of the elevator control apparatus according to the following embodiments, operations from the start of normal operation to implantation are almost the same as those explained in the first embodiment, and detailed explanation thereof is omitted.

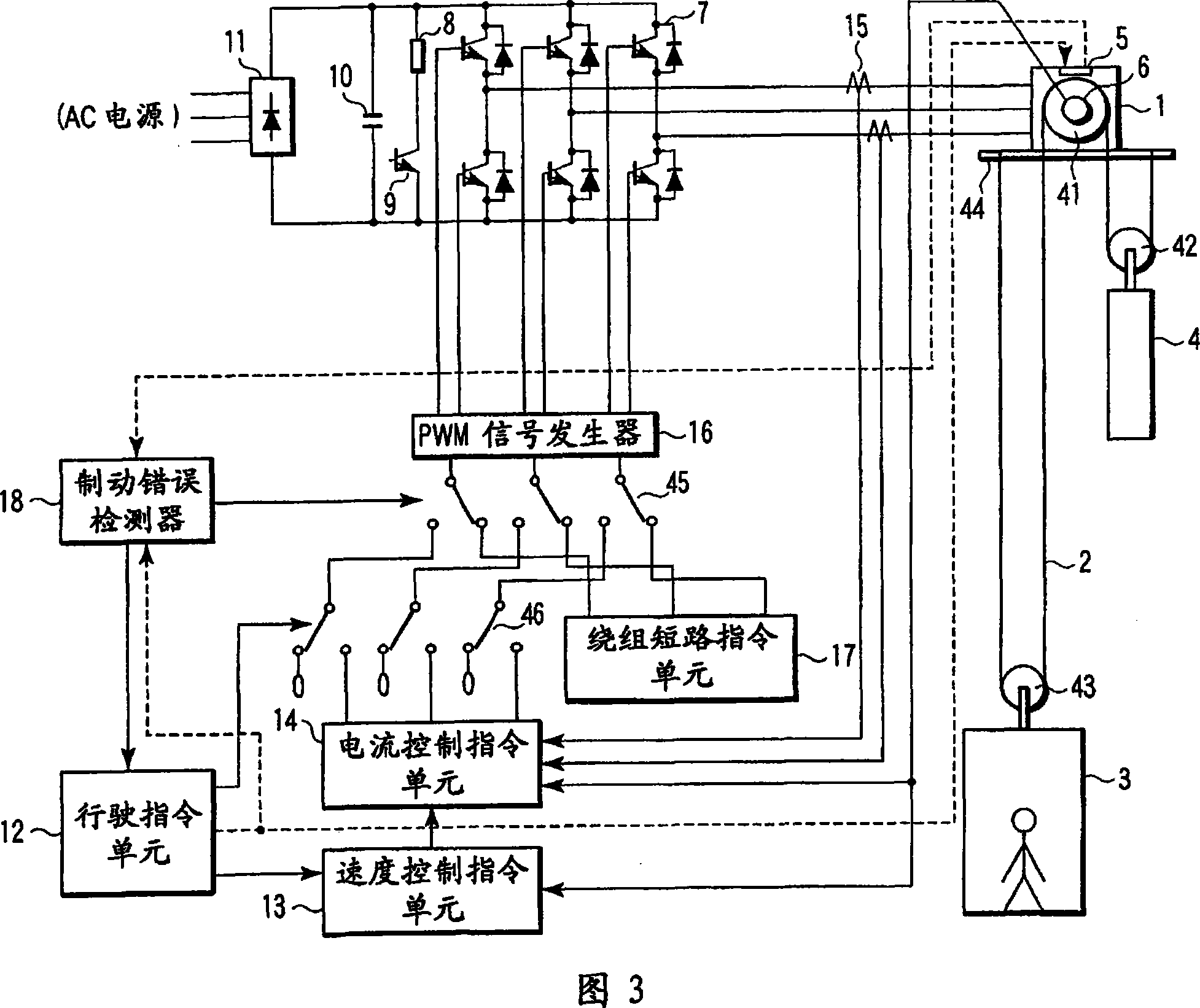

[0054] Fig. 4 shows a configuration example of an elevator control apparatus according to a second embodiment of the present invention.

[0055] As shown in FIG. 4, the elevator control apparatus according to the second embodiment of the present invention has a stop position memory 19 and a first free running detector 20 instead of the braking error detector 18 explained in the first embodiment.

[0056] When running the elevator car 3 , the travel command unit 12 outputs a brake...

Embodiment 3

[0068] A third embodiment of the present invention will be explained. Fig. 5 shows a configuration example of an elevator control apparatus according to a third embodiment of the present invention.

[0069] As shown in FIG. 5, the elevator control apparatus according to the third embodiment of the present invention has a second free running detector 21 instead of the braking error detector 18 explained in the first embodiment.

[0070] When running the elevator car 3 , the travel command unit 12 outputs a brake disconnection signal, and connects the second switch 46 to the current control command unit 14 .

[0071] In addition, the running command unit 12 outputs a brake release signal to the second free running detector 21 . The second free running detector 21 has the function of switching the first switch 45 and connects the first switch 45 to the current control command unit 14 when receiving the brake disconnection signal from the travel command unit 12 .

[0072] When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com